Combined type phase-change energy accumulation solar water heater

A solar water heater and phase change energy storage technology, applied in the directions of solar thermal energy, solar thermal power generation, solar heating systems, etc., can solve the problems of limited hot water, limited use range of solar water heaters, and impossible to have too much volume, etc. Heat utilization, processing and safety and reliability, the effect of increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

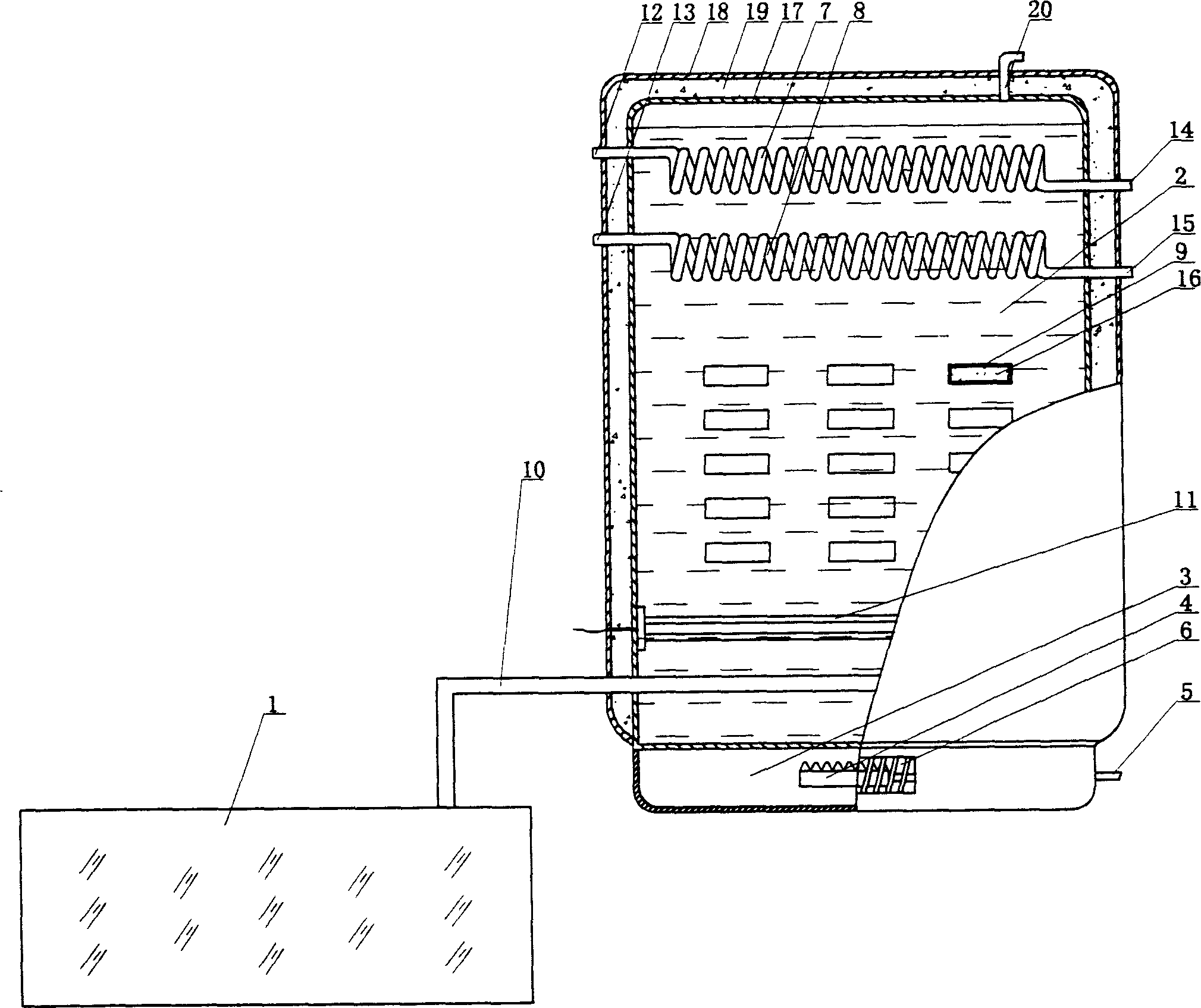

[0024] as attached figure 1 Shown, the composite phase change energy storage solar water heater of the present invention, its structure is made of heat collector 1 and water tank, wherein:

[0025] The heat collector 1 adopts a flat plate heat collector;

[0026] The water tank is composed of a water storage and heat preservation chamber 2 filled with a liquid heat exchange medium (water or oil) and a gas heating chamber 3 . The gas heating chamber 3 is arranged at the lower part of the water storage and heat preservation chamber 2, and a gas heating device 4 is arranged inside, and the gas connection pipe 5 protrudes to the outside of the casing of the gas heating chamber 3, and an air vent 6 is opened on the casing of the gas heating chamber 3 The top of the water storage and heat preservation chamber 2 is provided with two coil heat exchangers 7,8, and a plurality of phase change heat accumulators are arranged under the heat exchangers 7 and 8 in the water storage heat pre...

Embodiment 2

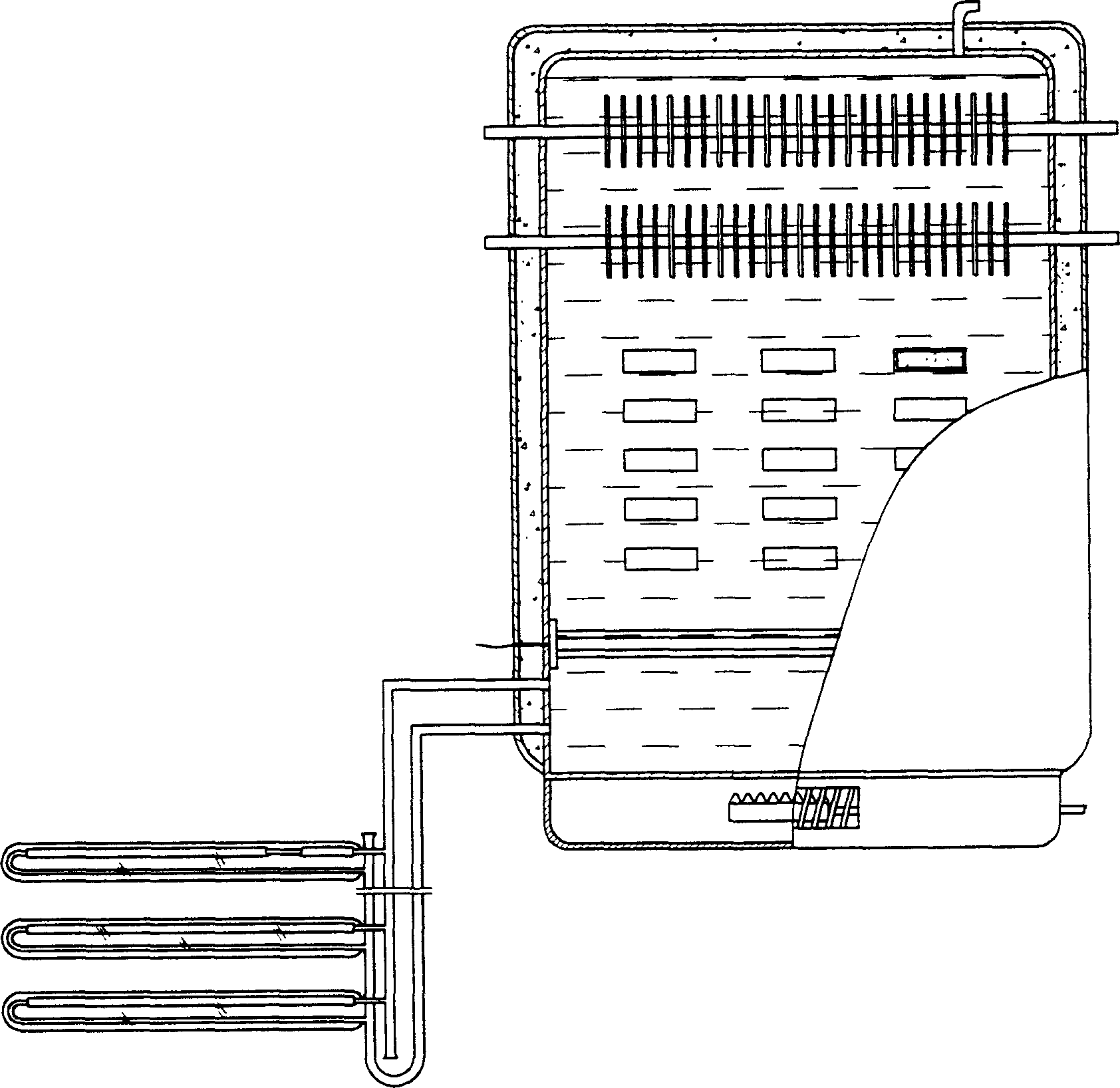

[0031] as attached figure 2 As shown, the heat exchanger in the water storage and heat preservation room adopts a fin heat exchanger; the heat collector is a vacuum tube heat collector; the heat collector and the water tank are connected by a medium microcirculation, and the heat medium of the heat collector Both ends of the circulation pipe are connected to the bottom of the water tank.

[0032] When the heat pipe is used to connect the heat collector and the water storage insulation room, the liquid heat exchange medium in the water storage insulation room absorbs the heat released from the condensation end of the heat pipe and does not enter the heat collector; the heat collector and the water storage are connected in the form of medium microcirculation In the heat preservation chamber, the liquid heat exchange medium in the water storage heat preservation chamber and the heat exchange medium in the heat collector circulate in order to achieve thermal balance, and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com