Testing device for magnetic field and magnetic force in three-dimensional space

A three-dimensional space and testing device technology, which is applied in the use of superconducting devices to measure the magnetic field, the size/direction of the magnetic field, etc., can solve the problem of not forming a testing system, and achieve the effects of reasonable design, simple operation and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

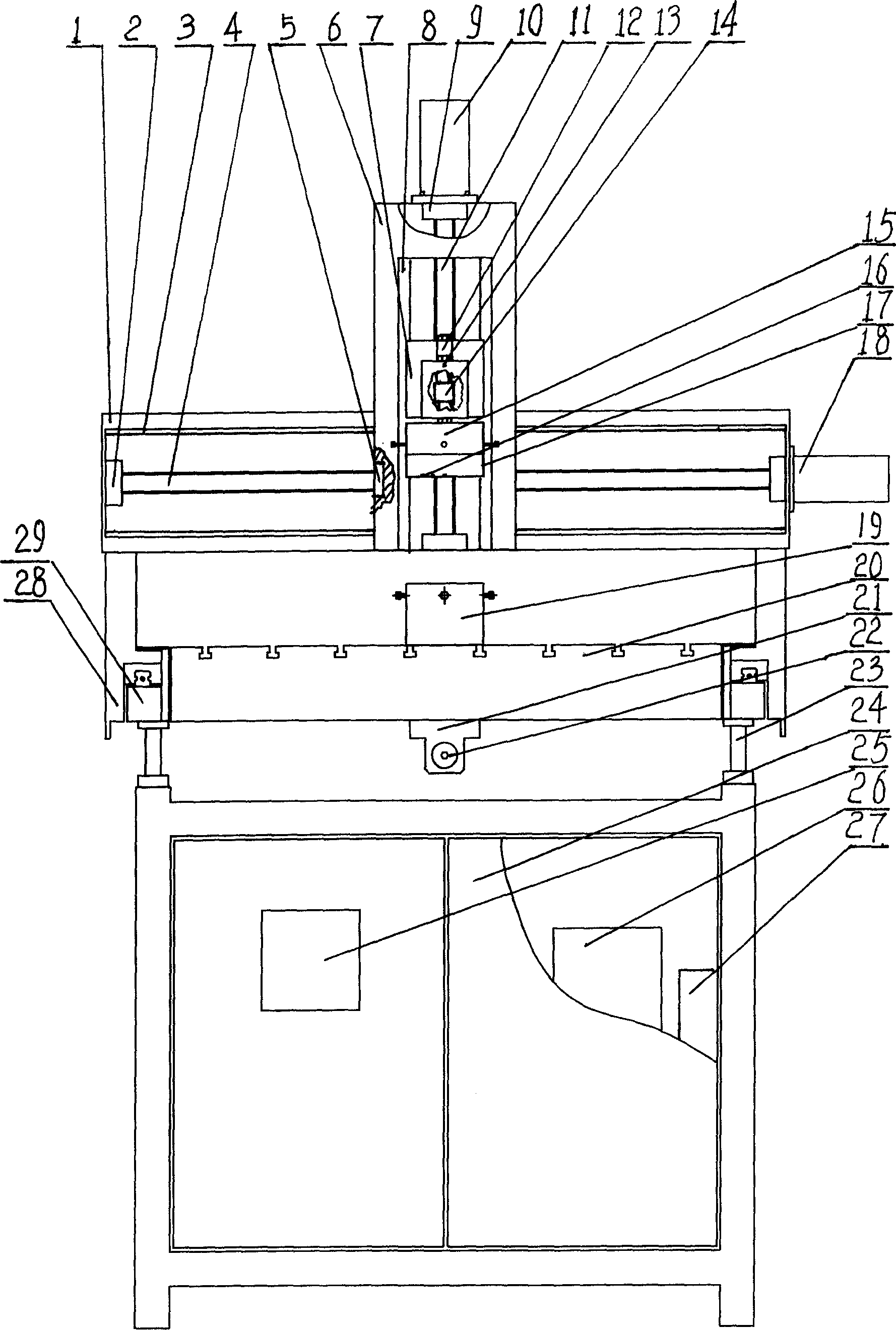

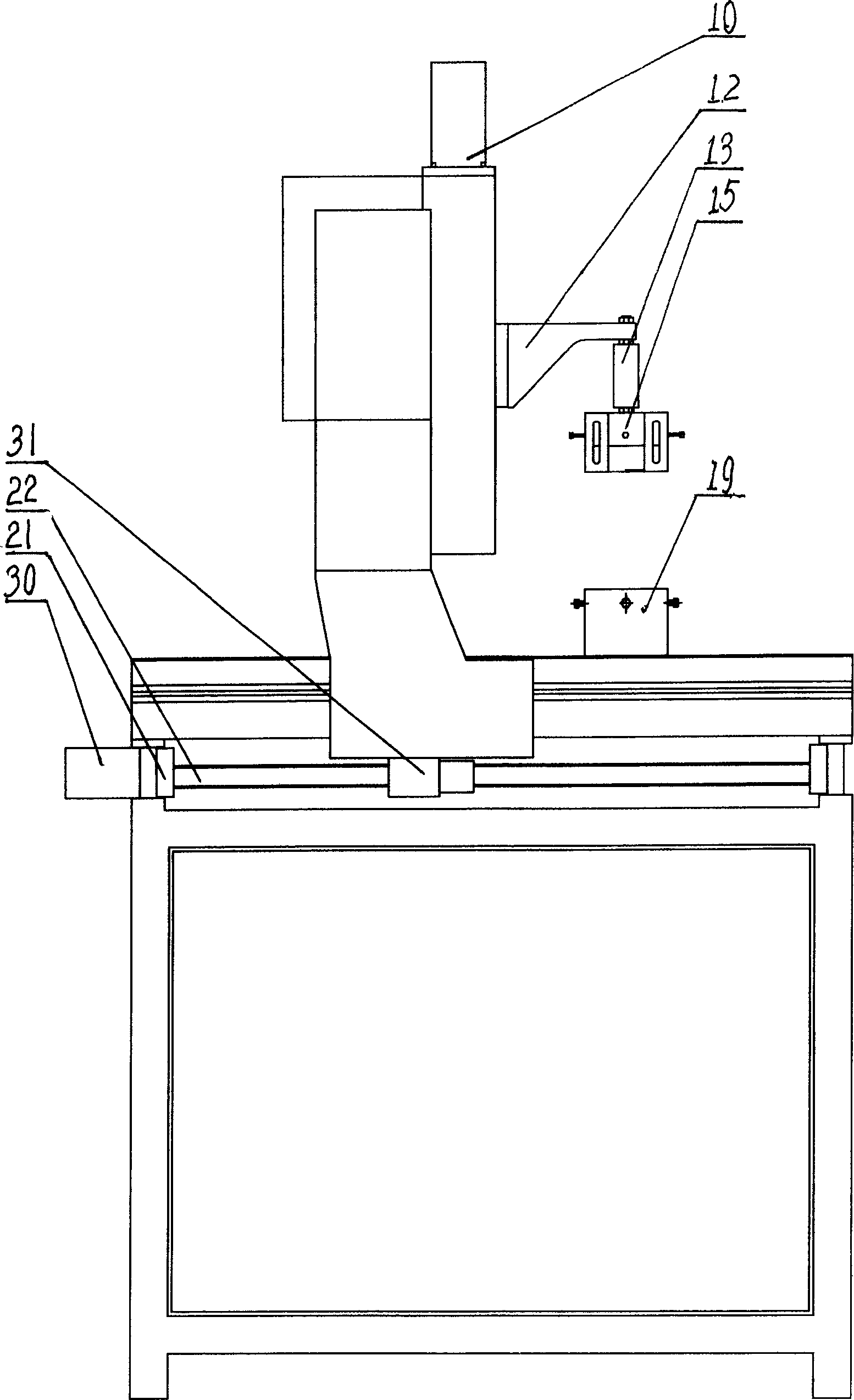

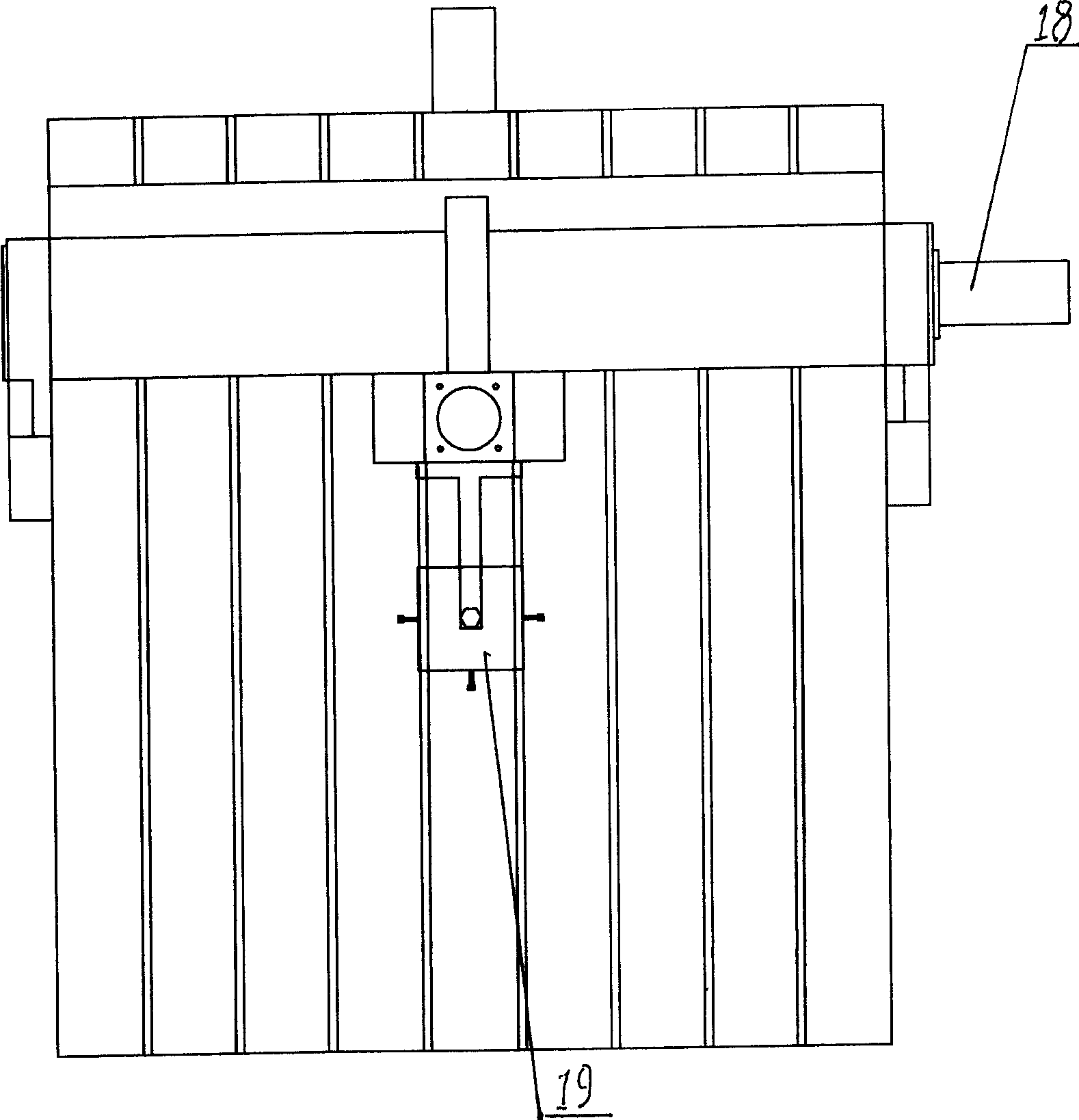

[0030] exist figure 1 , 2 , 3, the three-dimensional space magnetic field and the magnetic force testing device of the present embodiment are composed of beam 1, horizontal screw shaft sleeve 2, lateral moving track 3, horizontal screw mandrel 4, horizontal coupling sleeve 5, lateral moving support 6, vertical Moving support 7, vertical moving track 8, vertical screw bushing 9, vertical moving motor 10, vertical screw 11, cantilever 12, tension and pressure sensor 13, vertical connecting bushing 14, magnetic body fixture 15. Three-dimensional Hall probe 16, three-dimensional Hall probe frame 17, lateral movement motor 18, fixture for the measured part 19, working platform 20, longitudinal screw bushing 21, longitudinal screw 22, adjusting screw 23, control box 24, Computer 25, controller 26, programmable controller 27, longitudinal movement support 28, longitudinal movement track 29, longitudinal movement motor 30, longitudinal coupling axle sleeve 31 are connected and consti...

Embodiment 2

[0039] In this embodiment, one three-dimensional Hall probe 16 is fixedly installed on the three-dimensional Hall probe frame 17 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0041] The magnetic material clamp 15 of the present embodiment is: on the front, rear, left, and right inner sides of the clamp box 15-1, eight pressure sensors 15-10 are fixedly connected with the screw fastening connector and the connecting piece 15-9, each inner side Connect 2 pressure sensors 15-10. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0042] Working process of the present invention is as follows:

[0043] During the test, a corresponding constant voltage or constant current is supplied to the pull-pressure sensor 13, the pressure sensor 15-10 and the Hall plate 16-2. When the tension and pressure sensor 13 and the pressure sensor 15-10 are subjected to force, they will respectively convert the received force into a corresponding voltage signal and output it to the programmable controller 27, and then transmit the digital signal to the computer 25 after analog-to-digital conversion. Recording; when the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com