Steel structure dwelling house assembly

A steel structure and residential technology, applied in residential construction and other directions, can solve problems such as unfavorable industrial production, complex component connection, unclear force, etc., to achieve excellent fire performance, improve project quality, and good overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

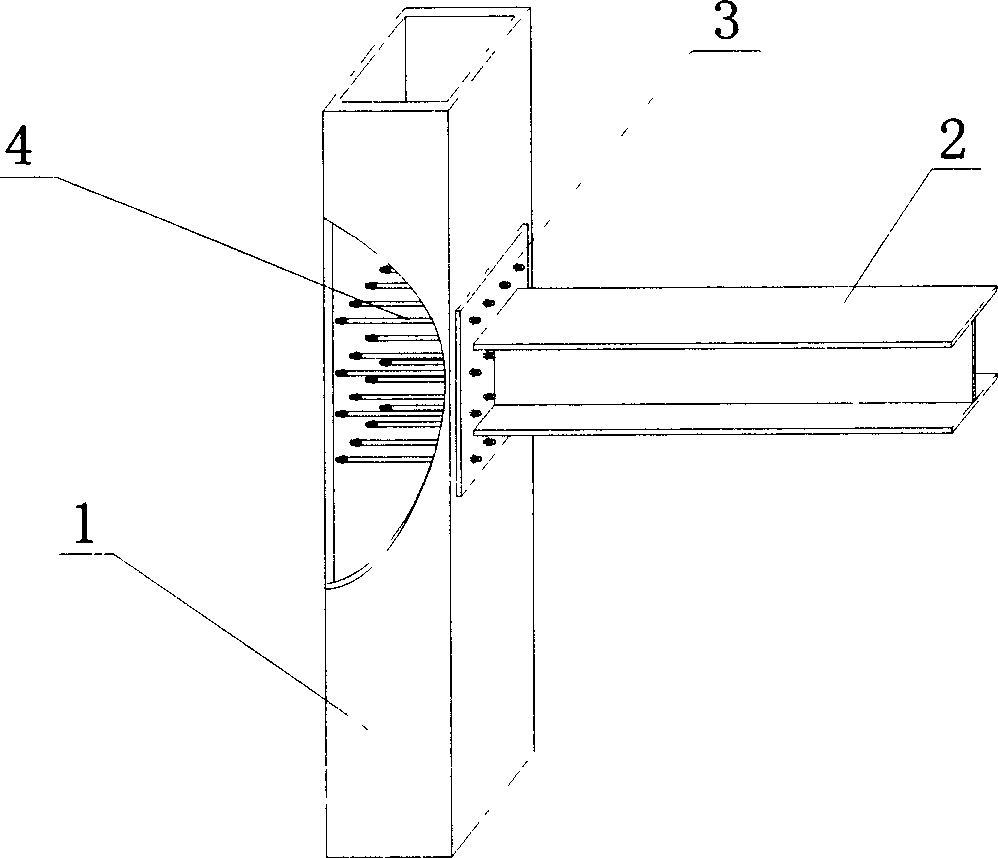

[0026] With reference to the accompanying drawings, a steel structure residential assembly includes a steel pipe concrete column 1, a steel beam 2, a support 6, a beam-column node between the steel tube concrete column 1 and the steel beam 2, a connection node between the support 6 and the beam-column, a floor 14 and The wall body 15 and the floor slab 14 are laid on the steel beams, and the wall body 15 is arranged between the columns.

[0027] The concrete-filled steel tube column 1 adopts a rectangular steel pipe with built-in high-strength concrete, and the steel beam 2 is an H-shaped steel beam; The long bolt 4 runs through the rectangular steel pipe concrete column 1; the end of the support 6 is fixed on the support connecting plate 7, the supporting connecting plate 7 is fixed on the end plate 3, the steel beam 2 is fixed on the end plate 3, and the end plate 3 passes through The long bolts 4 are connected to the rectangular steel pipe concrete column 1 , and the long b...

Embodiment 2

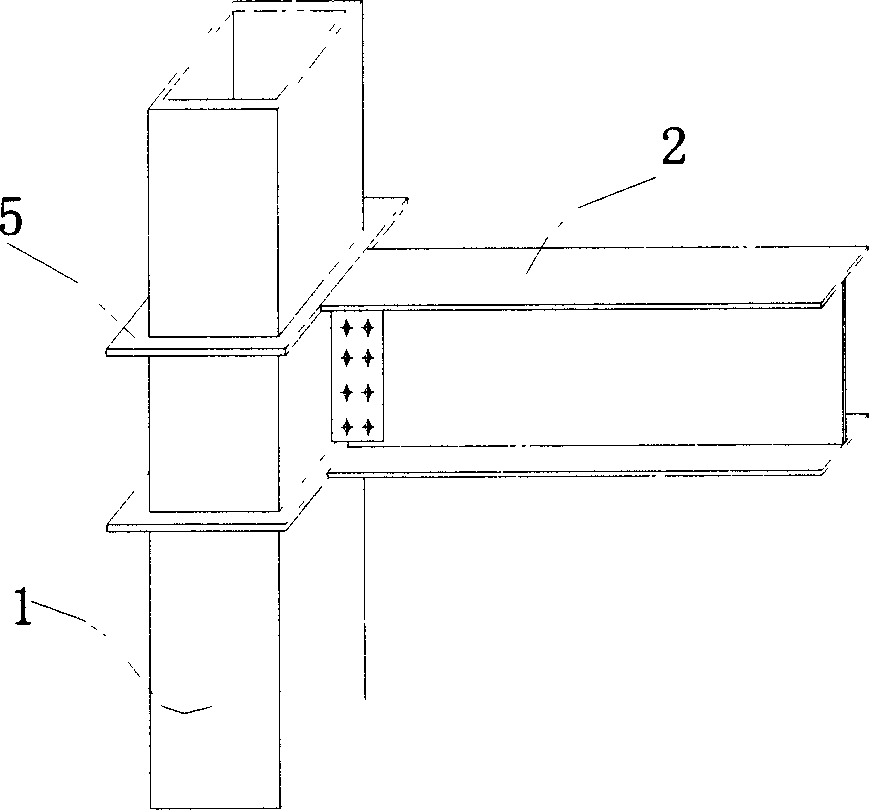

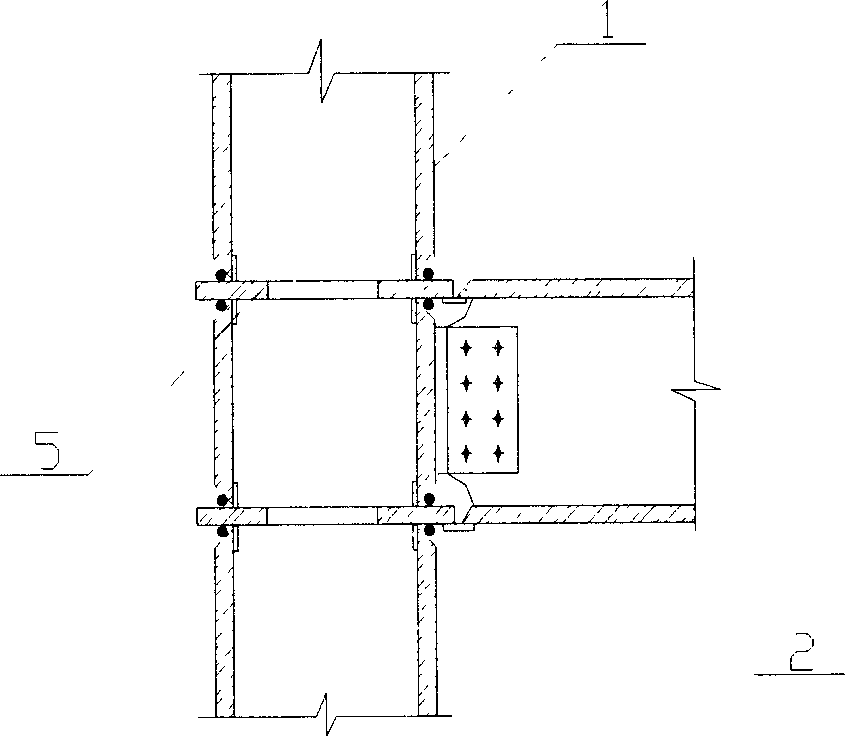

[0031] With reference to the accompanying drawings, a steel structure residential assembly includes a steel pipe concrete column 1, a steel beam 2, a support 6, a beam-column node between the steel tube concrete column 1 and the steel beam 2, a connection node between the support 6 and the beam-column, a floor 14 and The wall body 15 and the floor slab 14 are laid on the steel beams, and the wall body 15 is arranged between the columns.

[0032] The concrete-filled steel pipe column 1 adopts rectangular steel pipes with built-in high-strength concrete, and the steel beam 2 is an H-shaped steel beam; the beam-column joints are provided with an overhanging diaphragm 5, which has a hole in the center and connects with the rectangular concrete-filled steel pipe column. 1. Fixed connection, the overhanging transverse partition 5 includes upper and lower overhanging transverse partitions, and the upper and lower overhanging transverse partitions are fixedly connected with the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com