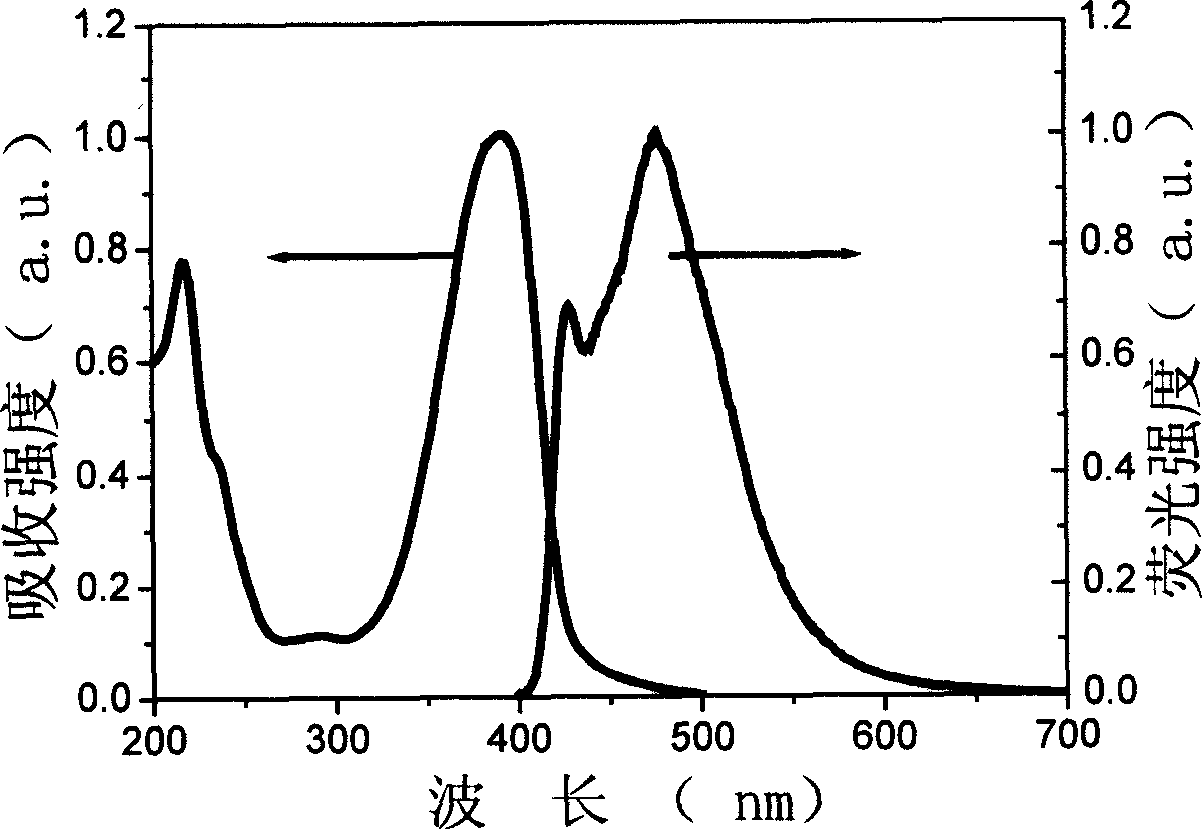

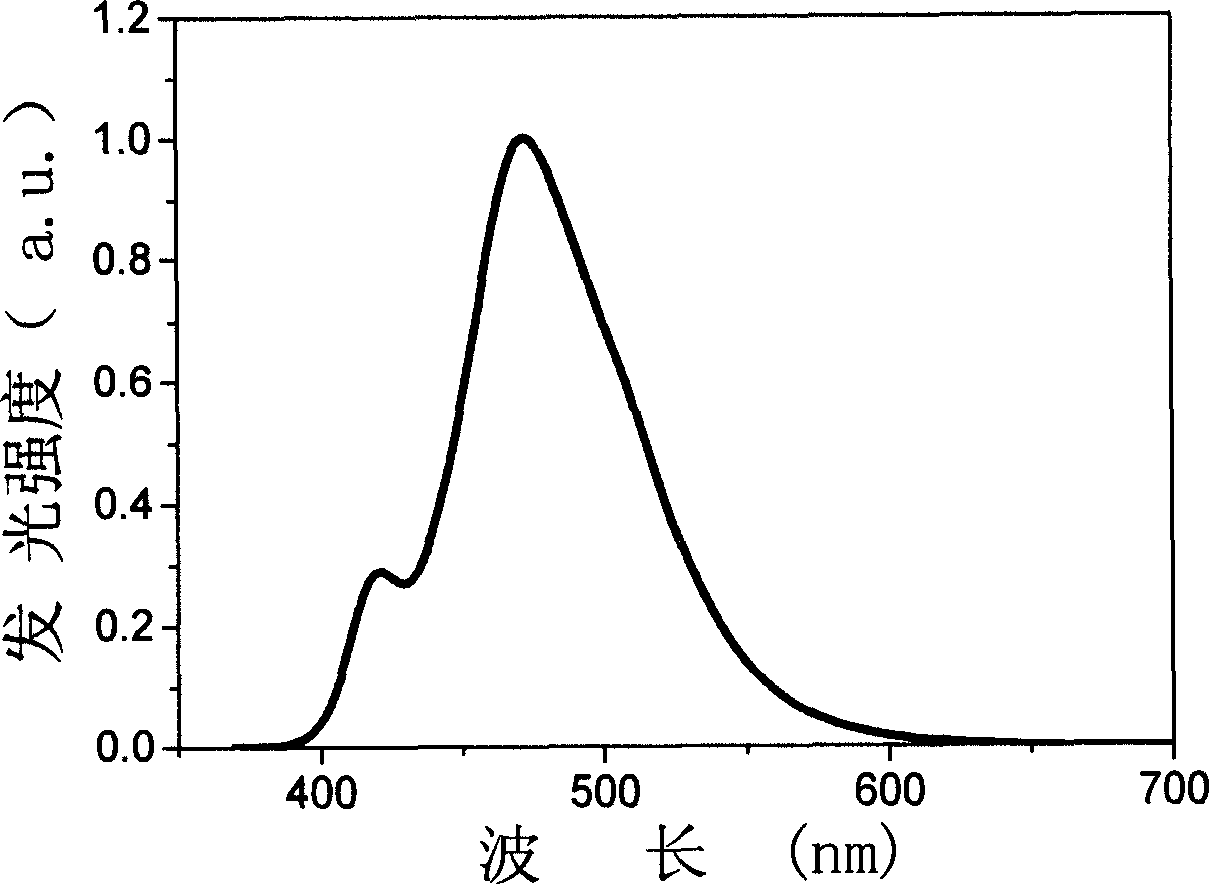

Blue light-emitting electroluminescent polyfluorene material and its prepn process

A polymer material and luminescent technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the practical gap, restrict the problems of polymer luminescent display screens, etc., and achieve the effect of enhancing luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

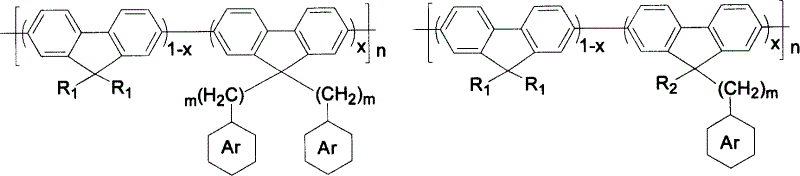

Method used

Image

Examples

Embodiment 1

[0056] Example 1: 2,7-dibromo-9-decyl-9-(2-(4-amino-1,8-naphthalimide-9-)ethyl-1-)fluorene

[0057] Under the protection of a nitrogen atmosphere, 2.12g (10.0mmol) of 4-amino-1,8-naphthalimide was dissolved in 60ml of dimethyl sulfoxide, and then 0.84g (15.0mmol) of powdered Potassium hydroxide, react at 50°C for ten minutes under electromagnetic stirring, then gradually add 3.426g (6.0mmol) 2,7-dibromo-9-decyl-9-(2-bromoethyl-1-) to the system fluorene. Reacted for 14 hours, washed repeatedly after chloroform extraction, dried, filtered, and column chromatography separated the product to obtain the pure intermediate product 2,7-dibromo-9-decyl-9-(2-(4-amino-1,8-naphthalene Imide-9-)ethyl-1-)fluorene 2.99g, yield 71%.

Embodiment 2

[0058] Example 2: 2,7-dibromo-9-decyl-9-(2-(4-dimethylamino-1,8-naphthalimide-9-)ethyl-1-)fluorene

[0059] Under the protection of nitrogen atmosphere, 0.351g (0.5mmol) 2,7-dibromo-9-decyl-9-(2-(4-amino-1,8-naphthalimide-9-)ethyl- 1-) Dissolve fluorene in 10 ml of dimethyl sulfoxide, then add 0.040 g (1 mmol) of 60% sodium hydride to the solution, react at 0°C for 10 minutes under electromagnetic stirring, and then add 0.71 g (5.0 mmol) to the system Iodomethane, reacted for 3 hours, washed repeatedly after chloroform extraction, dried, filtered, and the product was separated by column chromatography to obtain pure intermediate product 2,7-dibromo-9-decyl-9-(2-(4-dimethylamino -1,8-Naphthoimide-9-)ethyl-1-)fluorene 0.356 g, yield 92%.

Embodiment 3

[0060] Example 3: 2,7-dibromo-9,9-(10-(4-amino-1,8-naphthalimide-9-)decyl-1-)fluorene

[0061] Under the protection of a nitrogen atmosphere, 2.12g (10.0mmol) of 4-amino-1,8-naphthalimide was dissolved in 60ml of dimethyl sulfoxide, and then 0.56g (10.0mmol) of powdered Potassium hydroxide, reacted at 150°C for ten minutes under electromagnetic stirring, then gradually added 0.381g (5.0mmol) 2,7-dibromo-9,9-(10-bromodecyl-1-)fluorene to the system, and reacted After 14 hours, chloroform was extracted and washed repeatedly, dried, filtered, and the product was separated by column chromatography to obtain the pure intermediate product 2,7-dibromo-9,9-(10-(4-amino-1,8-naphthalimide- 9-)decyl-1-)fluorene 2.867g, yield 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com