Composite cylinder cap with air filter

A technology of air filter and cylinder head cover, which is applied in the direction of cylinder head, cylinder, machine/engine, etc. It can solve the problem that the effective ventilation area and effective filtration area of the filter element are not large enough, which affects ventilation, filtering effect and dust removal ability, air Inconvenient cleaning of the filter element, etc., to achieve the effect of saving installation and layout space, reducing weight and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

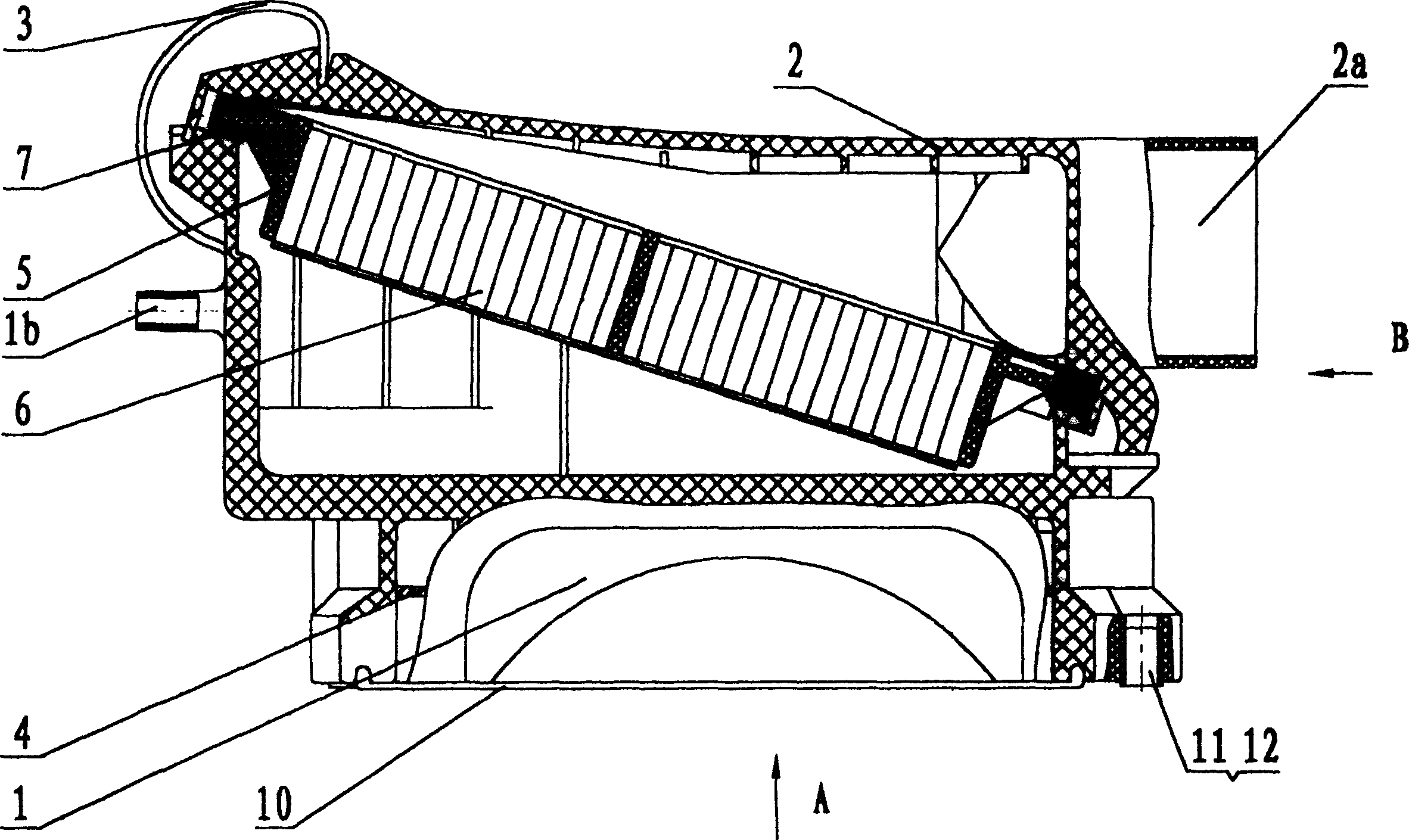

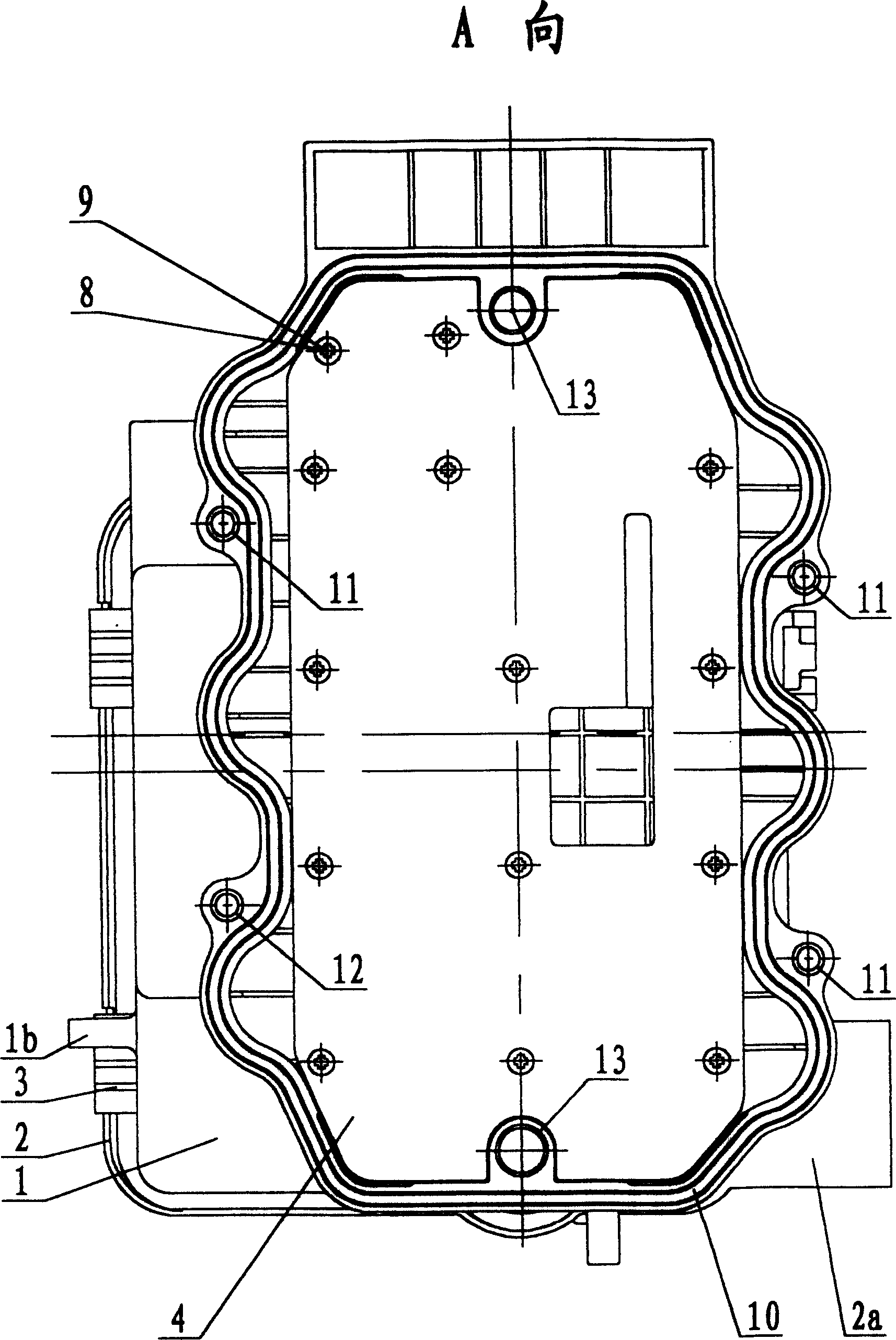

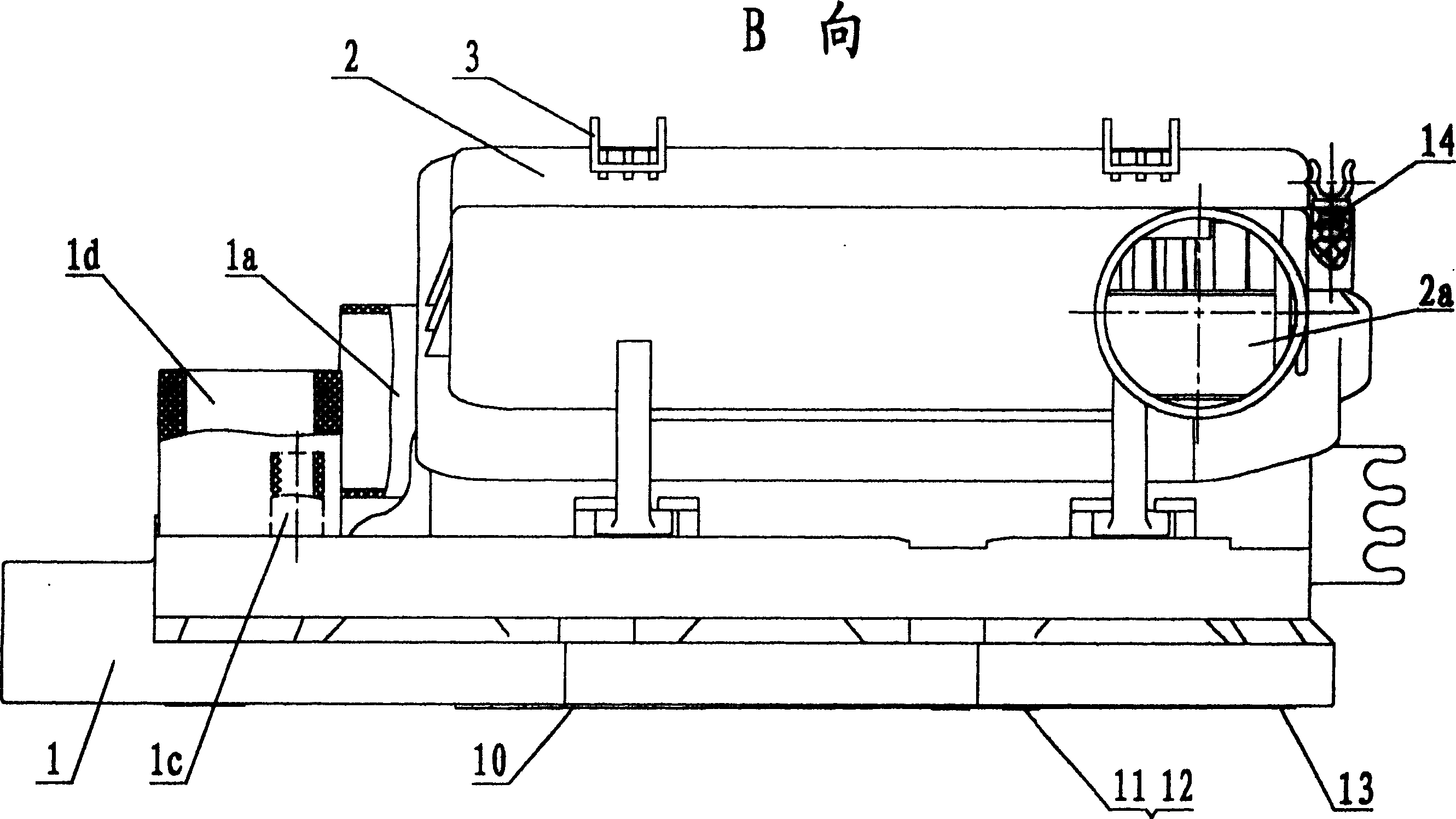

[0018] Embodiment: A kind of composite cylinder head cover with air filter (see Figure 1-3 ), comprising a cylinder head cover and an air filter, characterized in that the said cylinder head cover and the air filter are combined into one, which consists of: a cylinder head cover base 1, a cylinder head cover 2, a shell clip 3 , oil filter cover plate 4, filter element support 5, filter paper 6, filter element rubber ring 7, line card 8, sealing ring 9, screw 10, washer 11, and bolt metal bushing 11, 12, 13; The cylinder head cover base 1 and the cylinder head cover 2 of the filter element support 5, filter element rubber ring 7 and filter paper 6 of the filter have a sufficiently large hexahedral volume occupying the effective space of the front compartment of the automobile engine, and the filter element support 5 in the hexahedron The space is placed diagonally; the air intake hole 2a is placed on the cylinder head cover 2, the air outlet 1a, the vacuum air intake hole 1b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com