Tire noise reducing system

A tire and noise technology, applied in the field of tire noise reduction system, can solve problems such as harshness and increased sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

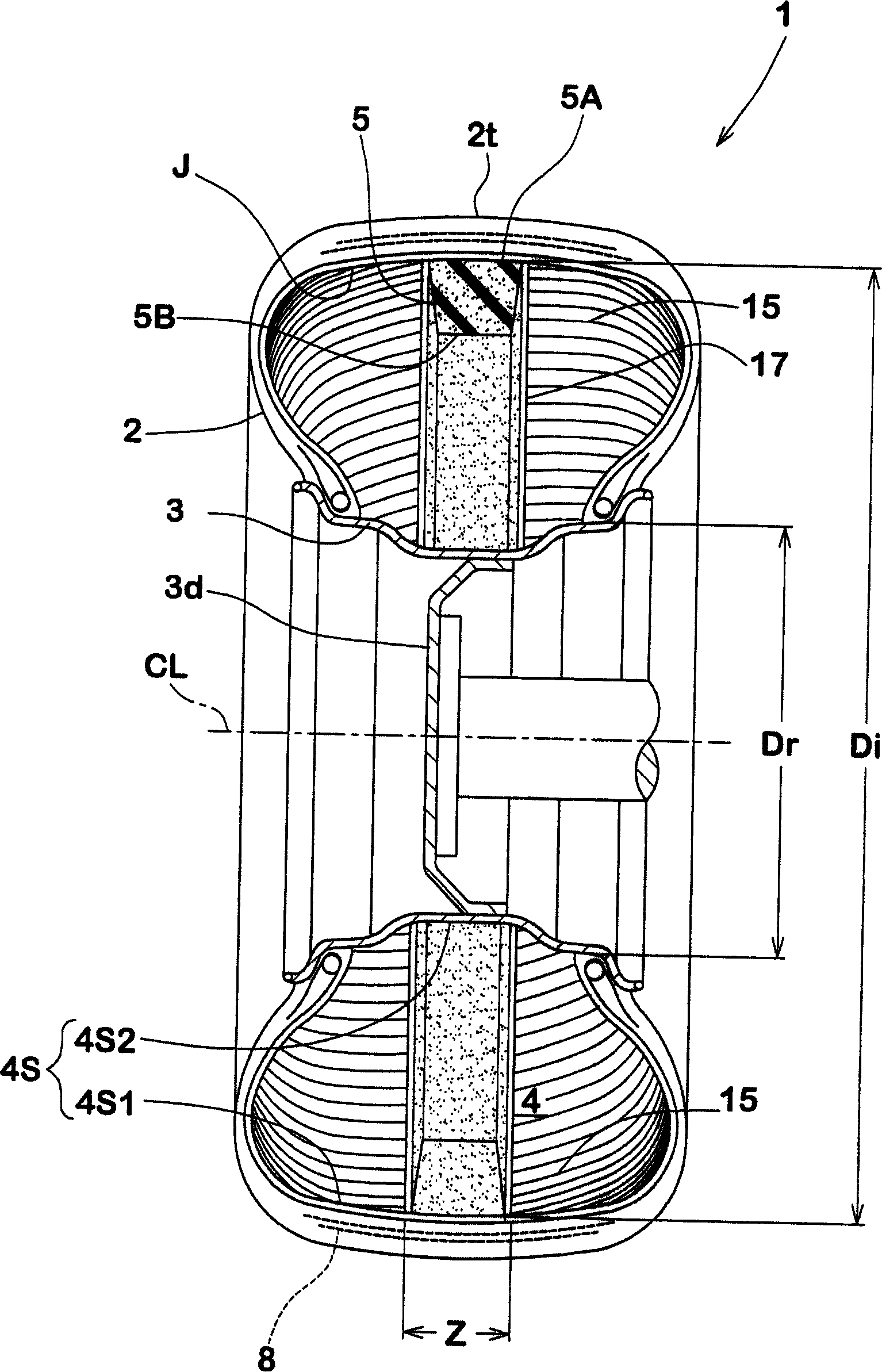

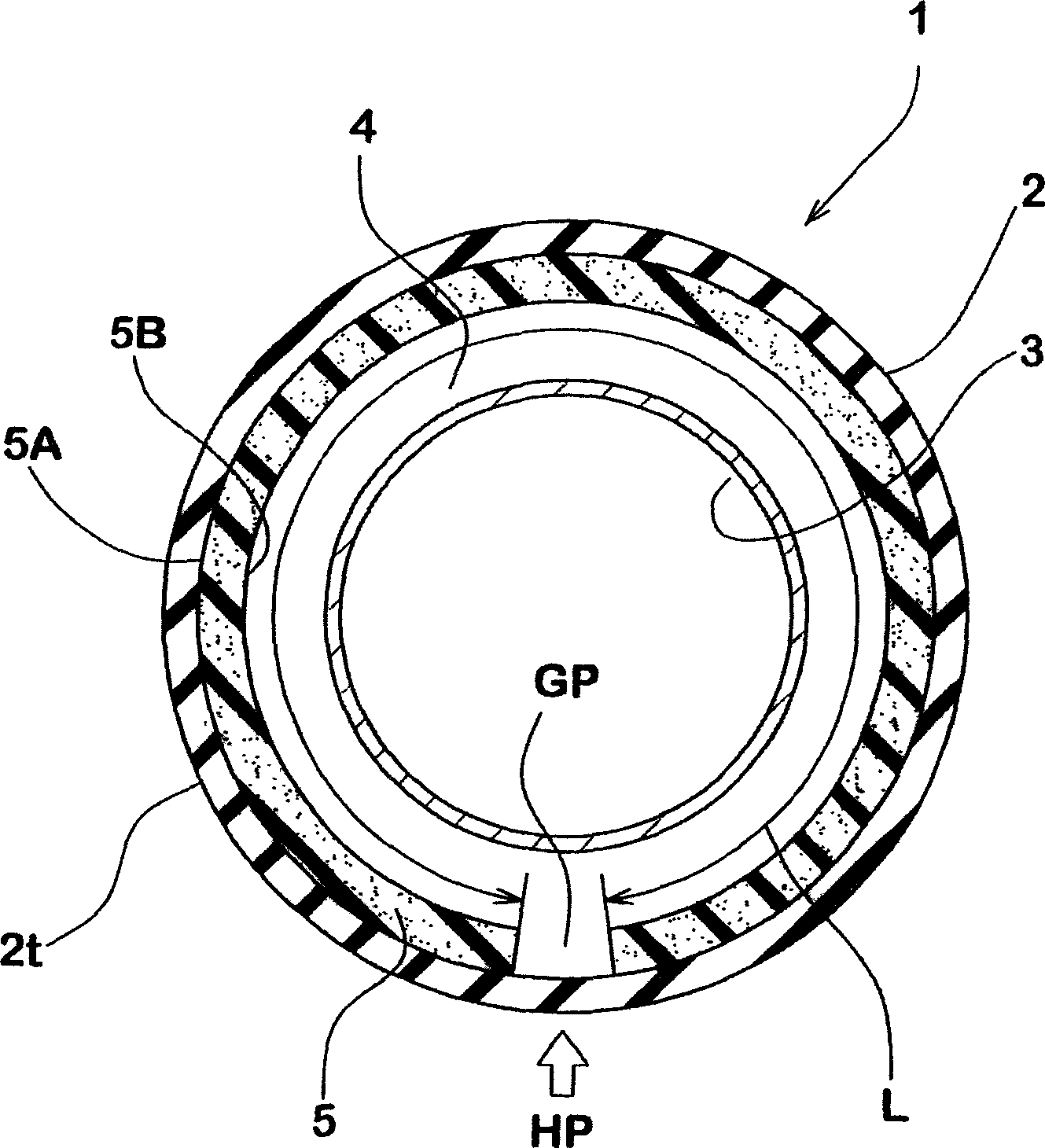

[0030] According to the invention, a muffler 5 is arranged in the cavity 4 of the assembly pneumatic tire 2 and rim 3 .

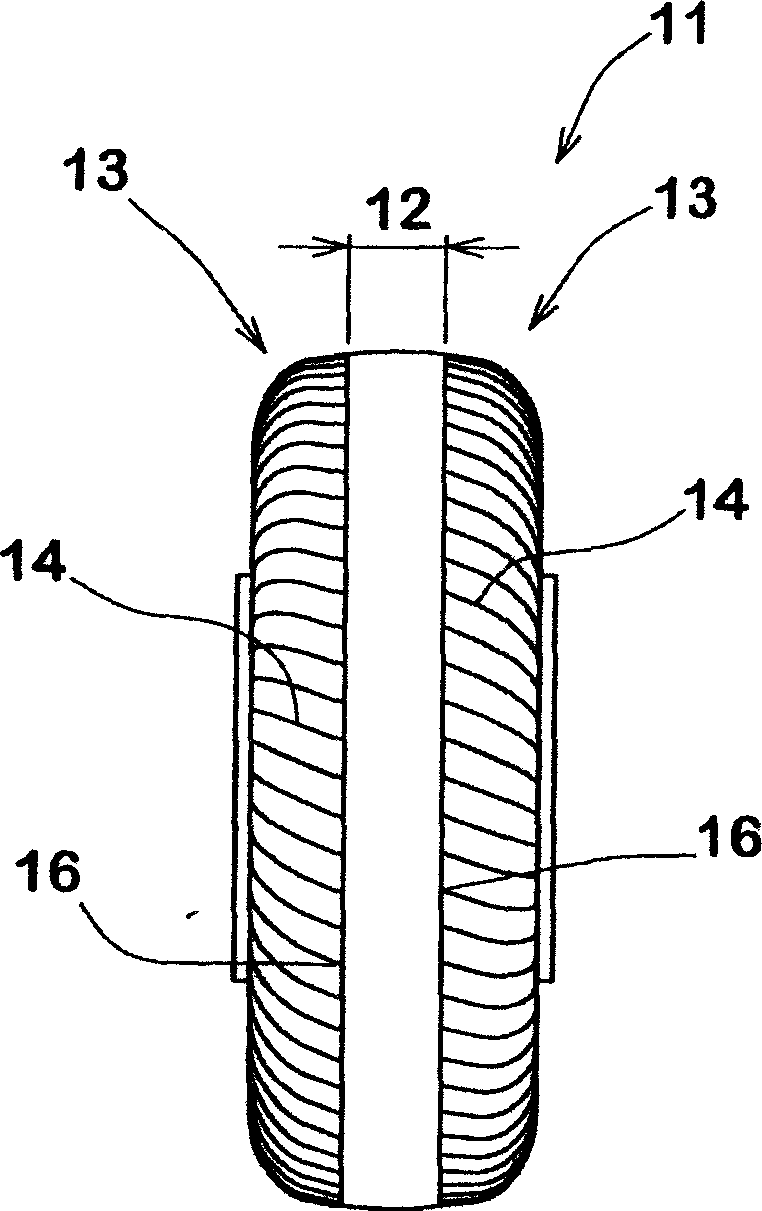

[0031] The pneumatic tire 2 has a tread portion 2t, a pair of sidewall portions 2s, and a pair of axially spaced bead portions 2b, thereby having a toroidal and annular tire hollow.

[0032] The rim 3 includes a pair of bead seats 3b for the beads 2b, a pair of flanges 3f extending radially outward from the bead seats 3b, and a bead seat located between the bead seats 3b. Between the rim well (rim well) 3w for tire installation.

[0033] When the tire hollow is closed by the rim, the rim 3 and the tire 2 mounted thereon form an annular cavity 4 . Here, the cavity surface 4s is defined as the surface facing said cavity 4, ie, the inner surface 4s1 of the tire and the inner surface 4s2 of the rim.

[0034] In this embodiment, the tire 2 is a radial tire for passenger cars. The rim 3 may be a specially designed rim, but in this embodiment a standard rim is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com