High light gain penetration reflective plate of liquid crystal display and its producing process

A liquid crystal display and reflector technology, which is applied in the field of penetrating reflectors, can solve the problems that the backlight cannot be fully utilized, the light transmission area cannot be too large, and the backlight is wasted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

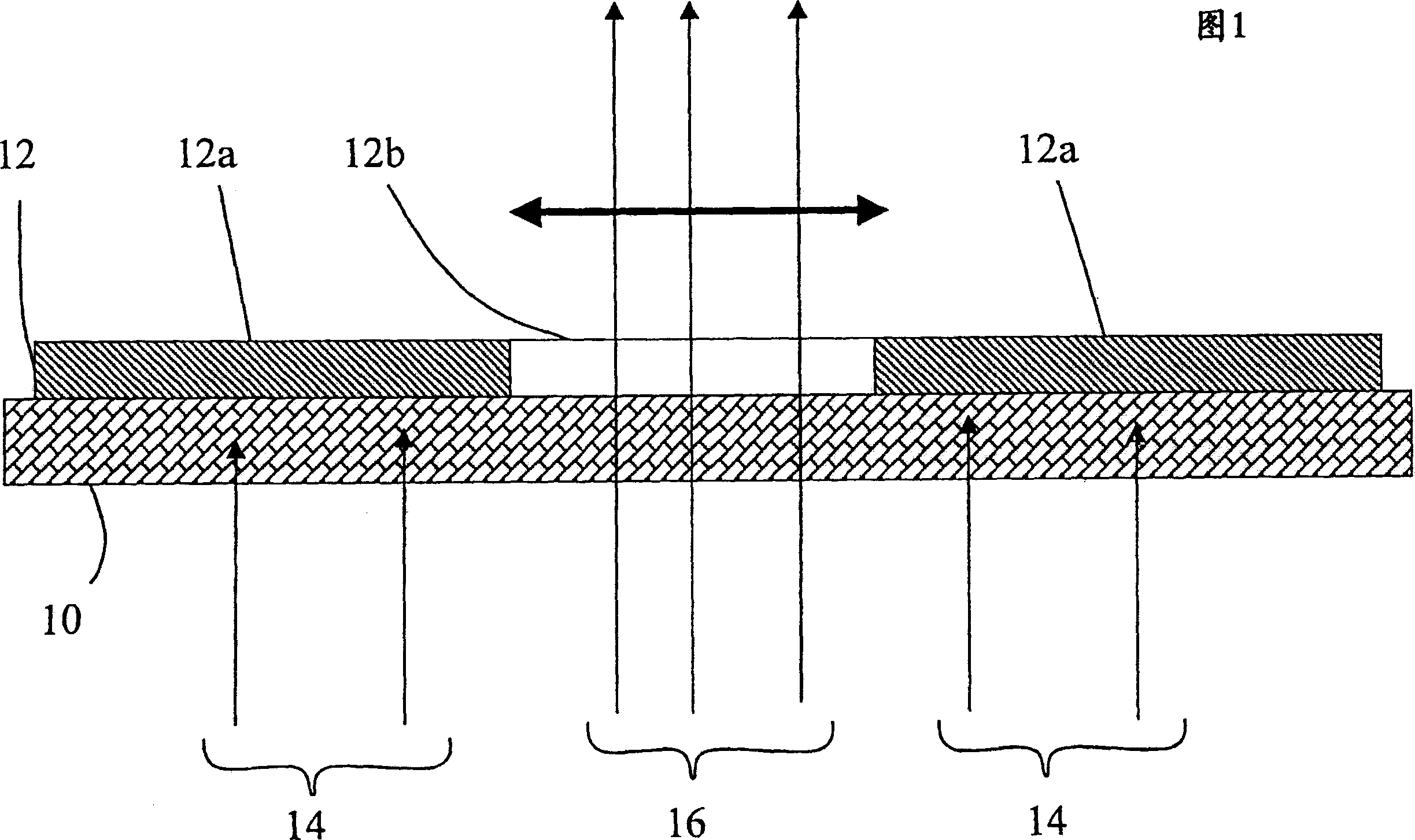

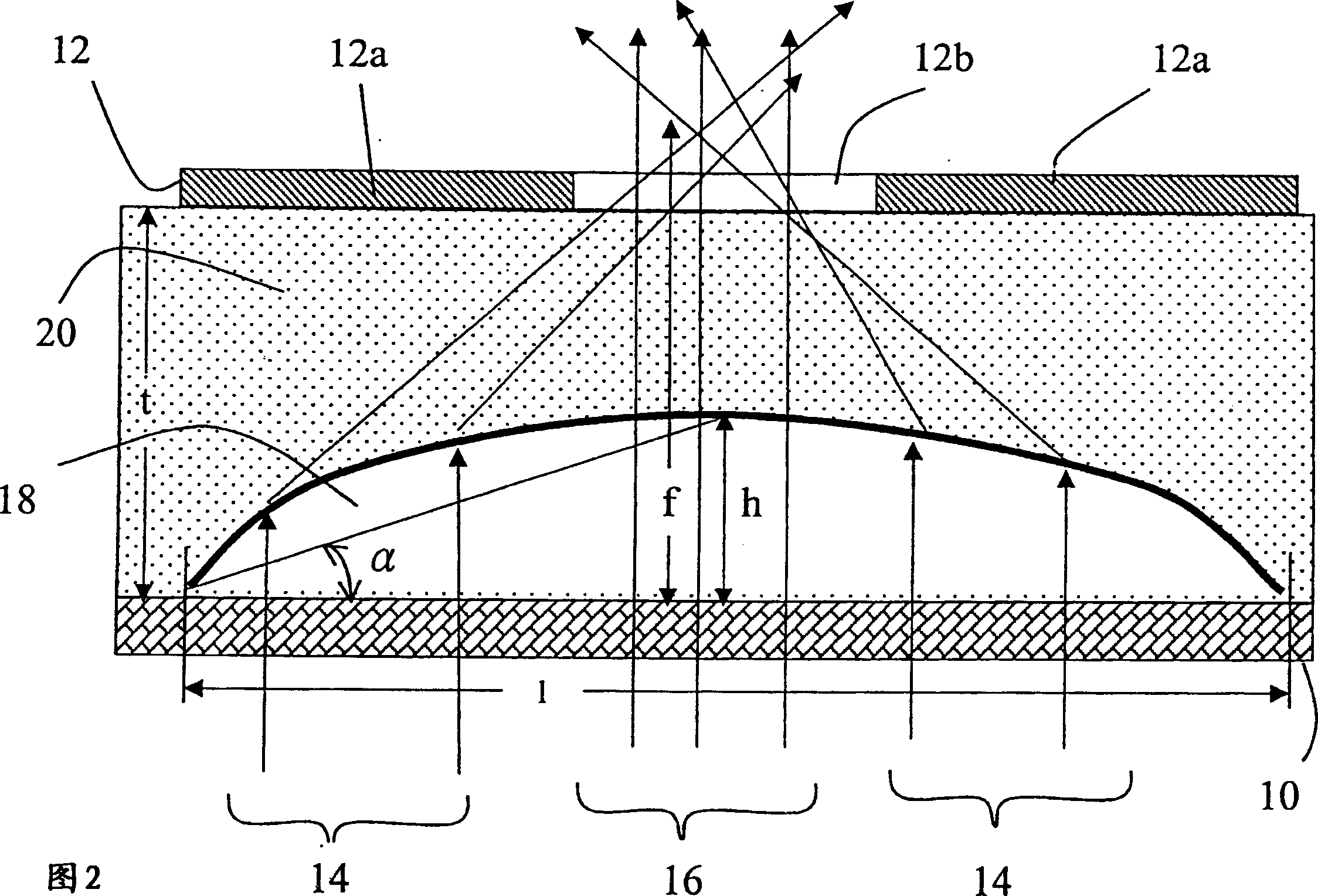

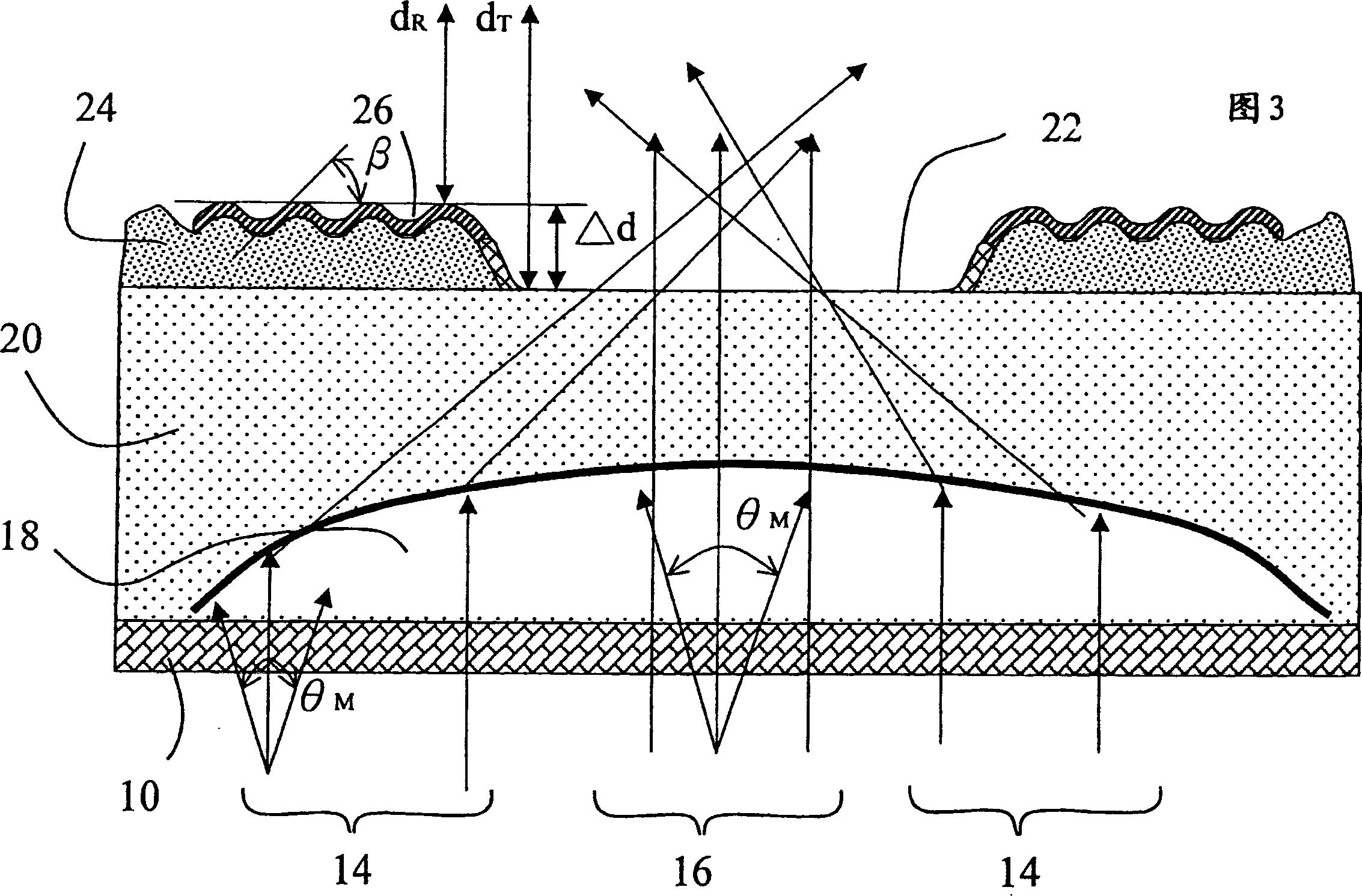

[0064] Fig. 2 is a schematic diagram of the first embodiment of the present invention. Between the substrate 10 and the transflector 12 are arranged microlenses 18 covered with an over coating 20 . The refractive index n of the microlens 18 L 1.4-2.5, the refractive index n of the flat layer 20 C less than n L . The microlens 18 collects the backlights 14 and 16 and projects them to the light-transmitting region 12b, so that the backlight 14 that could not be directly projected to the light-transmitting region 12b is utilized to increase the light gain. The LCD is composed of an upper plate and a lower plate sandwiching a liquid crystal. Switching elements, such as thin film transistors (TFT) or diodes, are formed on the lower plate. There are also liquid crystals and upper plates, which are prior art and are not described in detail in the figure. The transflector 12 can be formed by metal deposition and etching. In the device shown in Fig. 2, the microlens 18 has a widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Center height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com