Semiconductor laser driving current control method and multi-mode working driving power supply

A technology of driving current and driving power, which is applied in the field of driving power structure design, can solve problems such as inconvenient relationship list of semiconductor lasers, complicated algorithm of optical power source controller, and inability to guarantee stable output optical power, etc., to ensure optical power output, The effect of reducing energy loss and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

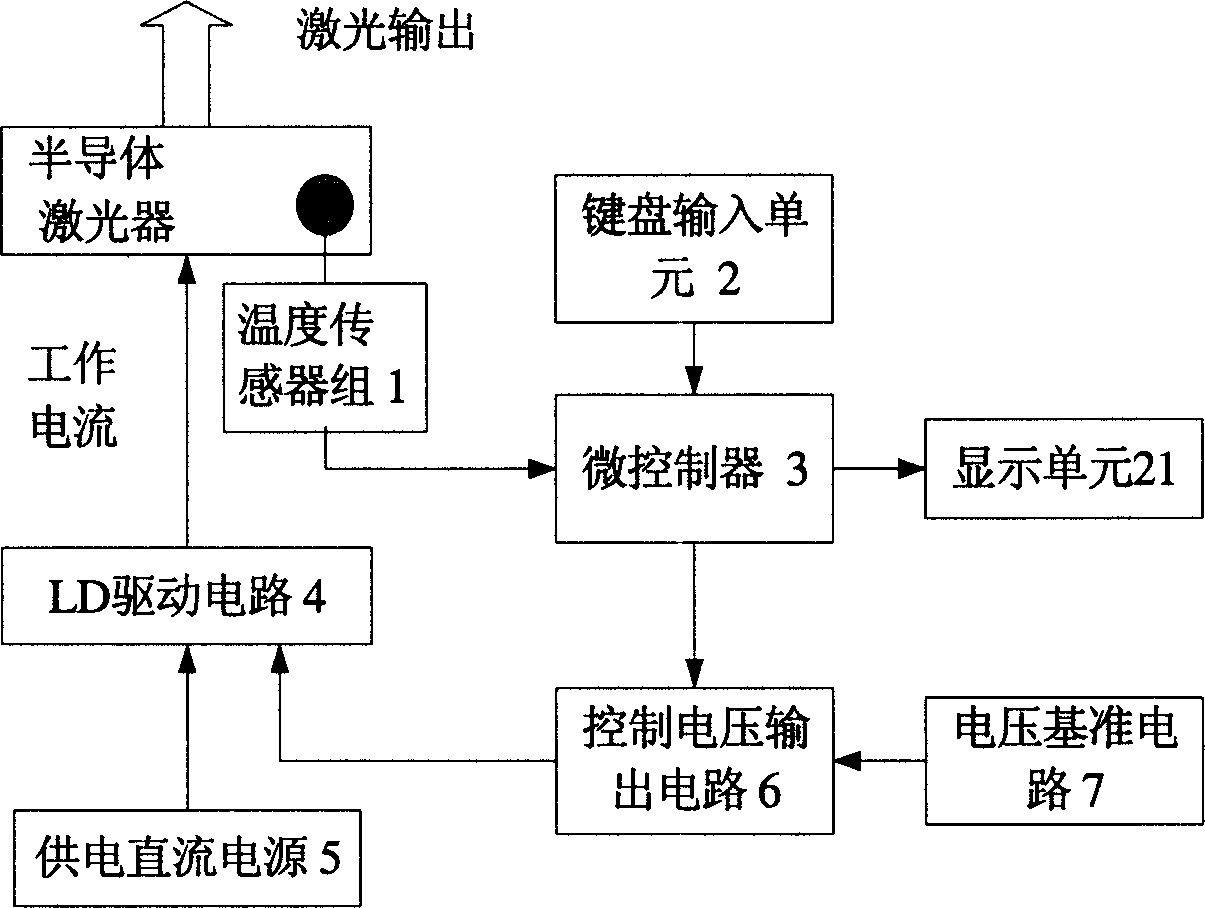

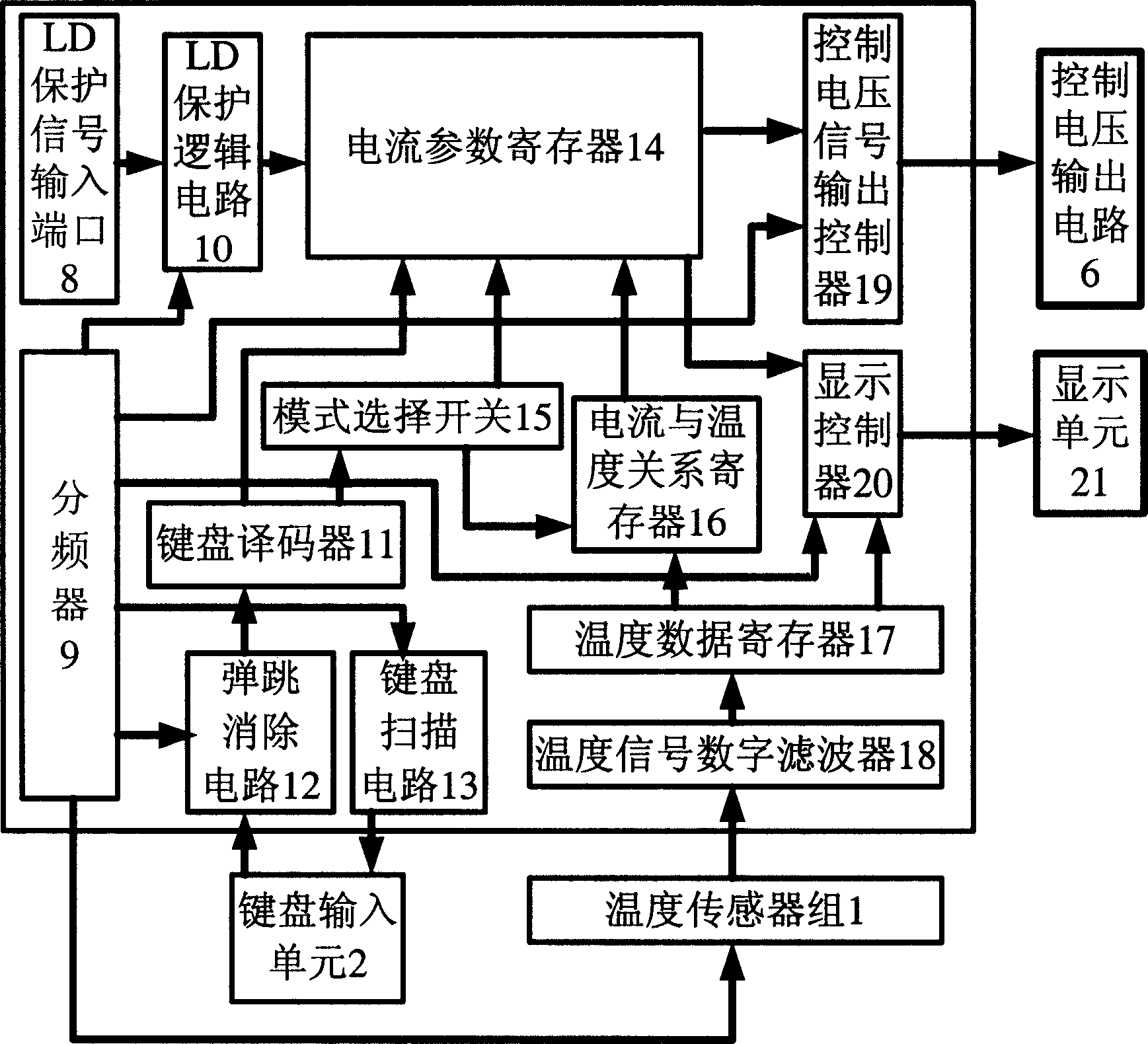

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] The control method of the driving current of the semiconductor laser according to the present invention uses the experimental test calibration method to obtain the required driving current value for the semiconductor laser to reach a certain output power at different temperatures, thereby obtaining the one-to-one correspondence between the temperature and the driving current value, Input the above-mentioned corresponding relationship into the microcontroller in the form of a list through the keyboard input unit; the experimental test calibration method is to test the driving current value required for the output of a certain power of the semiconductor laser at different temperatures, and form the relationship between the temperature and the driving current value. Correspondence (such as the temperature and drive current value correspondence table).

[0044] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com