Low power consumption brushless DC motor with Halbach magnet structure

A DC motor, low power consumption technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, electrical components and other directions, which can solve the problems of low air gap magnetic density, large air gap, and reduced motor power density. , to achieve the effect of small armature reaction, small volume and improved motor torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

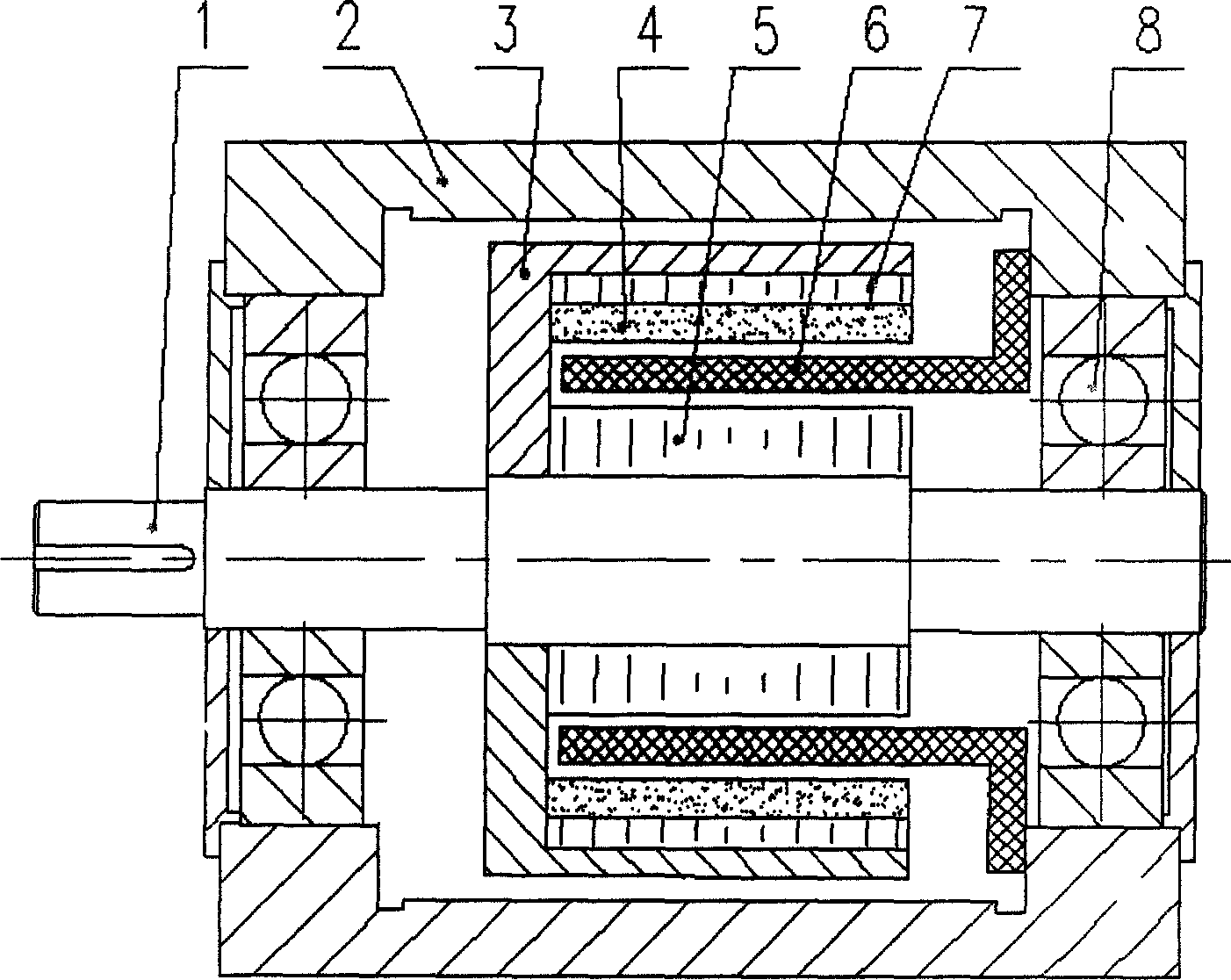

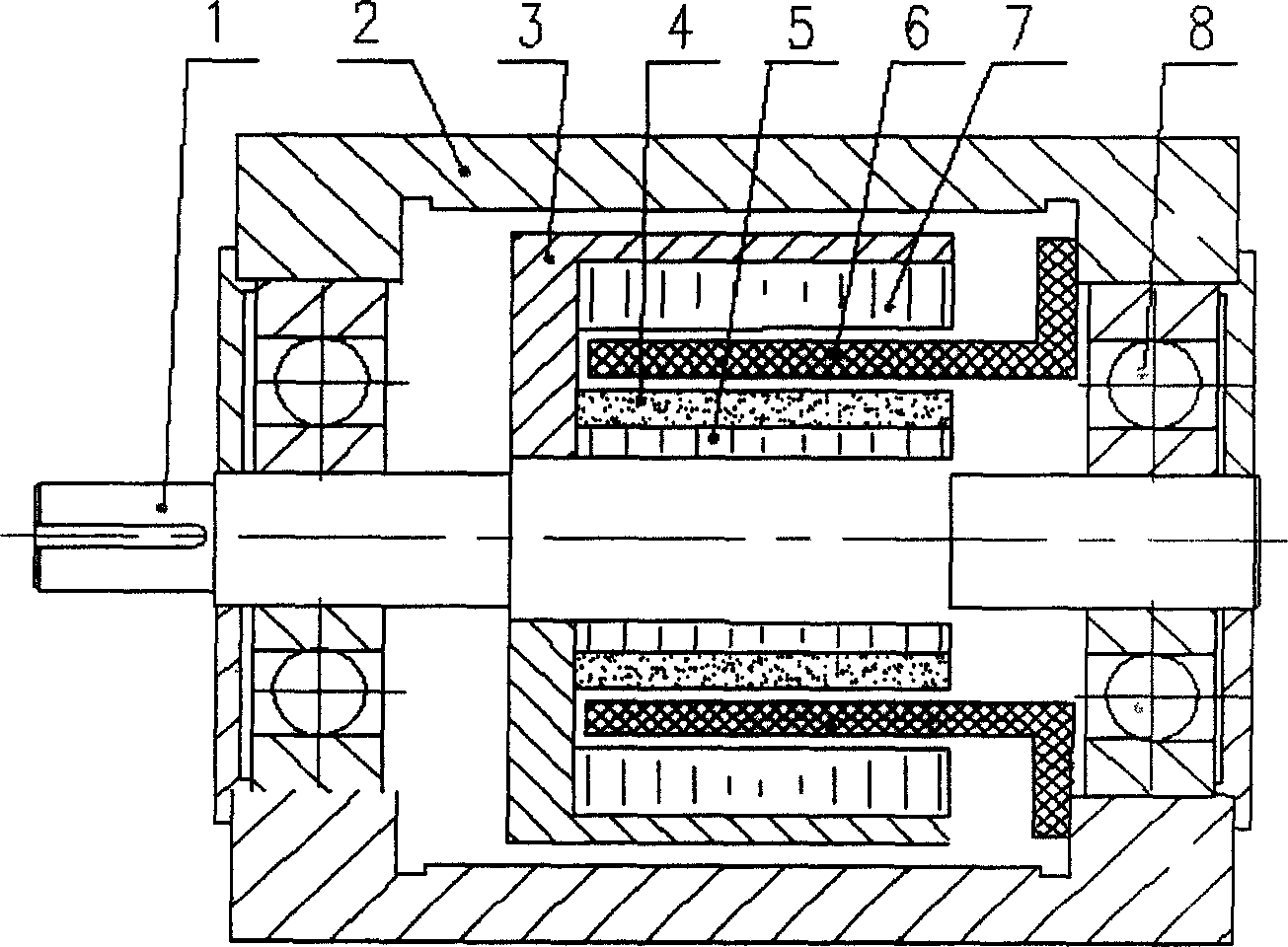

[0011] like figure 1 and figure 2 As shown, the brushless DC motor of Halbach magnet structure of the present invention is made up of rotor shaft 1, casing 2, sleeve 3, Halbach magnet 4, inner rotor iron core 5, hollow cup stator 6, outer rotor iron core 7 and bearing 8, The outer rotor core 7 and the inner rotor core 5 are connected to the rotor shaft 1 through the sleeve 3, so that the outer rotor core 7 and the inner rotor core 5 rotate together with the rotor shaft 1, and the Halbach magnet 4 can be installed on the inner rotor core 5, such as figure 1 As shown, it can also be installed on the outer rotor core 7, such as figure 2 As shown, considering that the rotor will generate a huge centrifugal force when it rotates at a high speed, the Halbach magnet 4 is generally placed on the outer rotor core 7 .

[0012] When the rotor shaft 1 and the sleeve 3 are made of magnetically conductive materials, both the outer rotor core 7 and the inner rotor core 5 need to be fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap