Control device and method for a vibratory machine

The technology of a vibration generator and a control unit, which is applied to the device in the direction of travel and the control field of the unbalanced mass adjustment device, can solve the problems such as the uncontrollable adjustment of the moving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

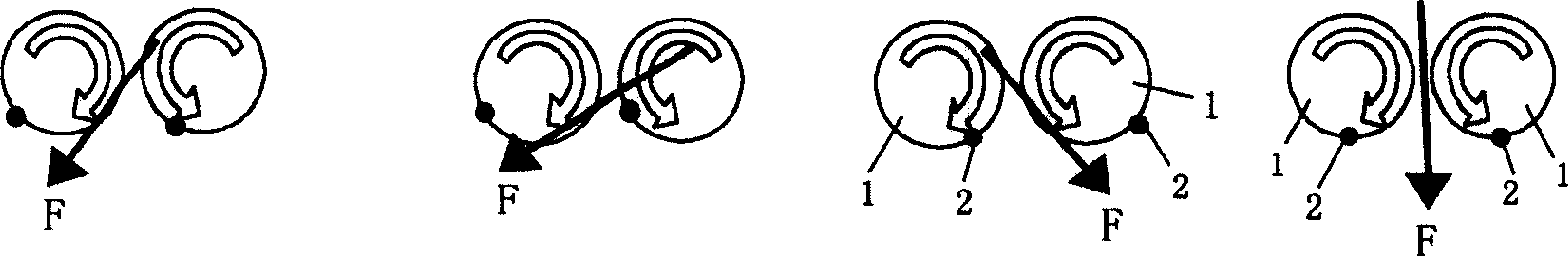

[0025] figure 1 It is schematically shown how a vibration generator, in particular a soil compactor with vibrating plates, moves forwards and backwards. Vibration occurs by turning the unbalanced mass 2 vibrating plates with opposite directions of rotation. A centrifugal force F of the unbalanced masses 2 is generated depending on the phase angle of the unbalanced masses 2 with respect to each other. In the case of in-situ vibration, the centrifugal force F generated acts in the vertical direction. As the vibration generator moves back and forth, the generated centrifugal force F is inclined to the vertical direction at a certain inclination angle so that the generated centrifugal force F not only has a vertical vibration component, but also generates a horizontal vibration component, causing the vibration generator to move.

[0026] Such as figure 1 As shown, the two unbalanced mass axes 1 move in the opposite direction to the unbalanced mass 2 indicated by the dot. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com