Antistatic optical film, antistatic adhering optical film, their prodn. and image display

An optical film, anti-static technology, applied in the field of anti-static adhesive optical film, can solve the problems of difficult adhesive layer, lack of stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

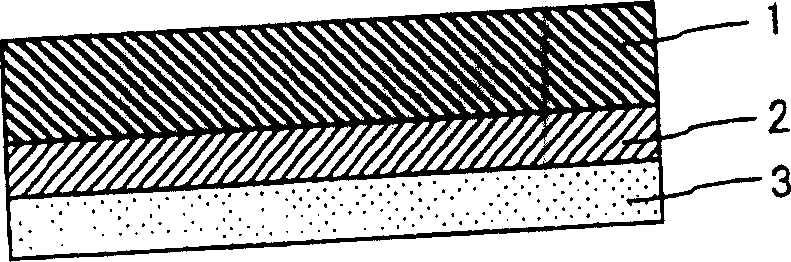

Image

Examples

Embodiment 1

[0112] (production of optical film)

[0113] A polyvinyl alcohol film having a thickness of 80 μm was stretched 5 times in an iodine aqueous solution at 40° C., and then dried at 50° C. for 4 minutes to obtain a polarizer. A triacetyl cellulose film was bonded to both sides of the polarizer using a polyvinyl alcohol-based adhesive to obtain a polarizing plate.

[0114] (Formation of antistatic layer)

[0115] An aqueous solution having a solid content concentration of 0.8% was prepared using a polyurethane-based resin as a binder and a water-soluble polythiophene-based conductive polymer. The ratio (weight ratio) of the binder to the conductive polymer is the former: the latter = 10:1. The solution was coated on one side of the polarizer so that the thickness after drying reached 100 nm, and dried at 80° C. for 2 minutes to form an antistatic layer.

[0116] (formation of adhesive layer)

[0117]As the base polymer, dissolve 95 parts of butyl acrylate, 5 parts of acrylic a...

Embodiment 2

[0121] In the formation of the antistatic layer in Example 1, an antistatic adhesive polarizing plate was produced in the same manner as in Example 1, except that the polyurethane resin used as the binder was changed to an acrylic resin.

Embodiment 3

[0123] In the formation of the antistatic layer in Example 1, except that the polyurethane resin used as the binder was changed to a polyester resin, an antistatic adhesive polarizing plate was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap