Magnetic control type flexible polisher with air bag

A technology for flexible polishing and polishing tools, which is used in manufacturing tools, grinding/polishing equipment, wheels with flexible working parts, etc. Flexibility cannot be controlled online, etc., to achieve the effect of improving polishing effect, improving polishing efficiency, and stable normal polishing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

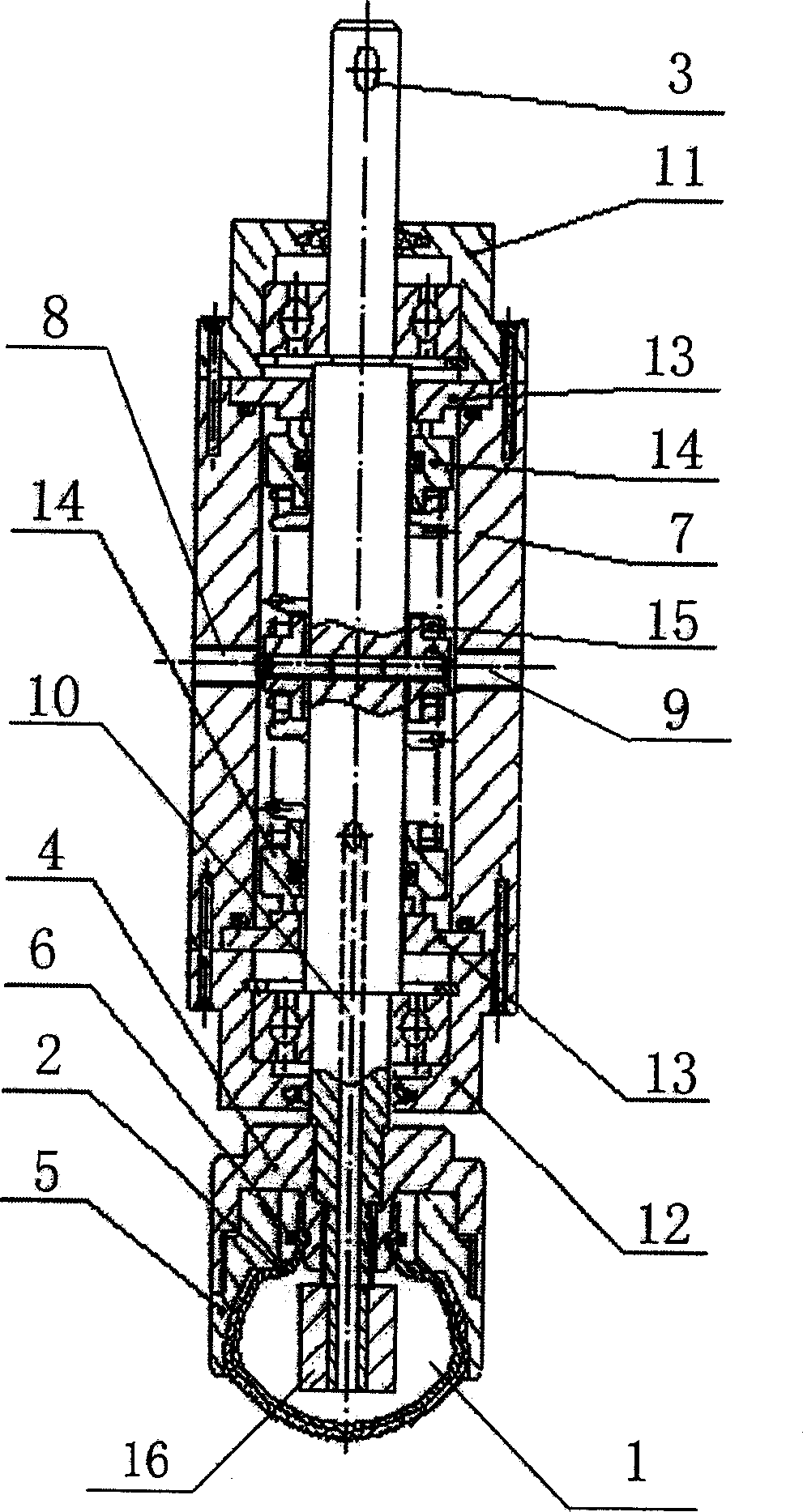

[0019] The present invention will be further described below in conjunction with the drawings.

[0020] Reference figure 1 , A magnetically controlled airbag flexible polishing tool, the polishing tool includes an airbag 1, the front end of the airbag 1 has a polishing cloth 2 as a working surface, the airbag 1 is installed in a holder, and the holder is installed On a rotating shaft 3 that can drive the holder to rotate, the holder includes a polishing head outer cover 4, a polishing head inner cover 5, and the polishing head outer cover 4 is connected to the rotating shaft 3 through threads, and the polishing cloth 2 is connected to the polishing cloth 2 with resin. The head cover 4 is glued into one body and reinforced with a circlip 6. The polishing head inner cover 5 is a part of the polishing cloth 2 for shape determination and shaping. It is connected with the polishing head cover 4 through threads. After the polishing cloth 2 is inflated, The contact part of the polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com