Inertial rotation axial braking device for gardening tool

A technology of rotating axial and garden tools, applied in the direction of brake types, brake actuators, brake components, etc., can solve the problems of inconvenient processing and maintenance, complex manufacturing structure, high manufacturing cost, etc., and achieve high braking reliability , simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

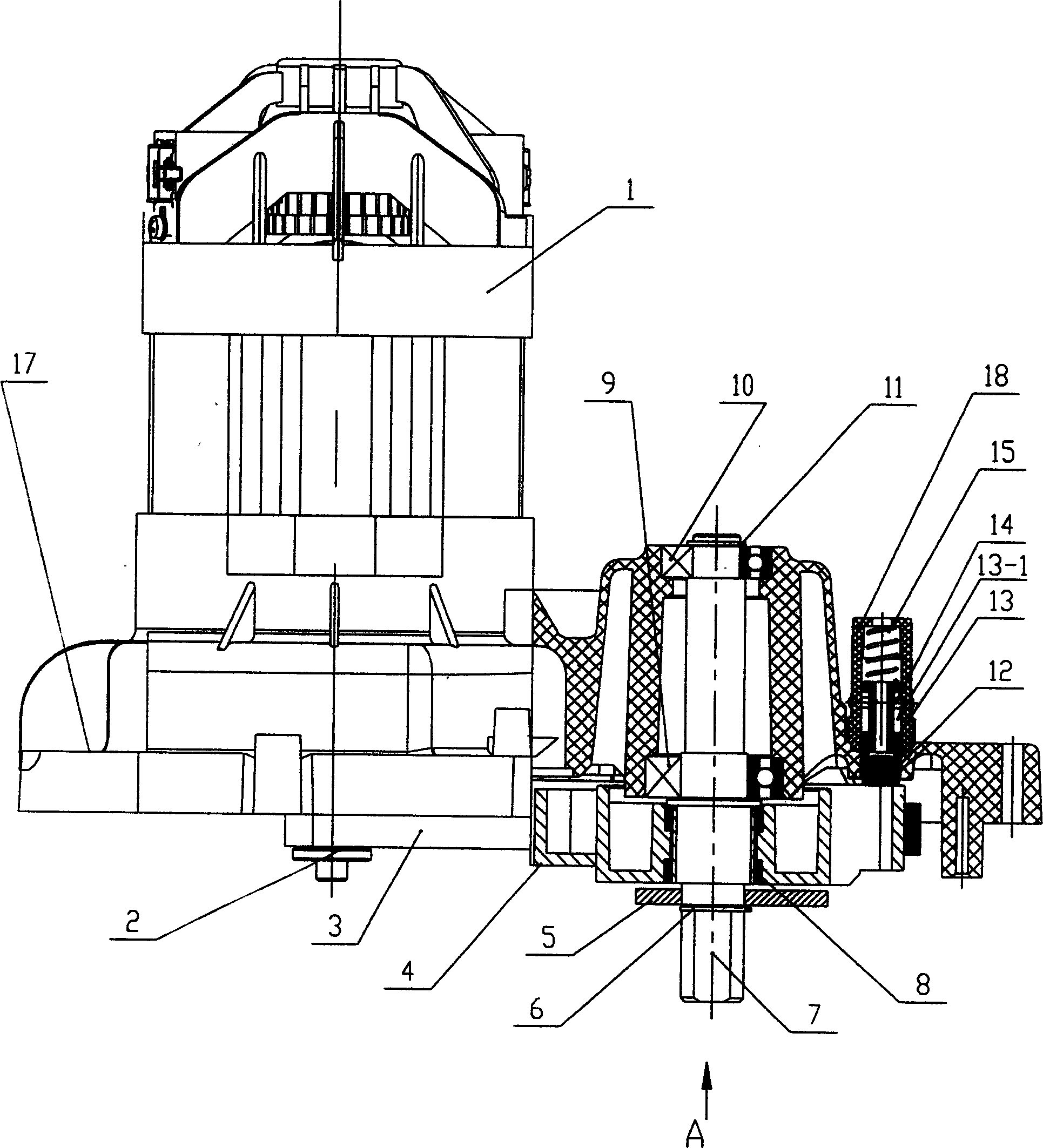

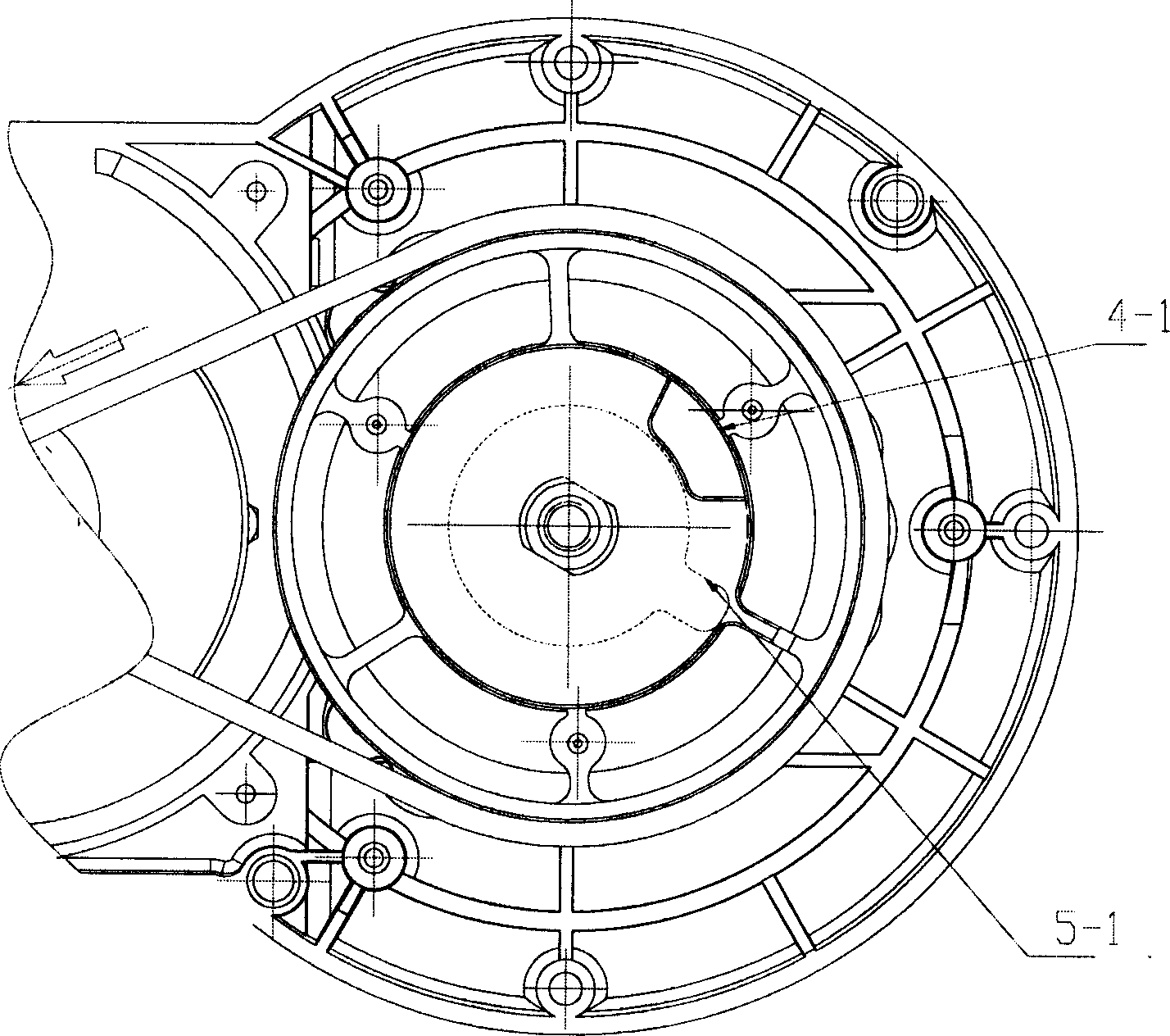

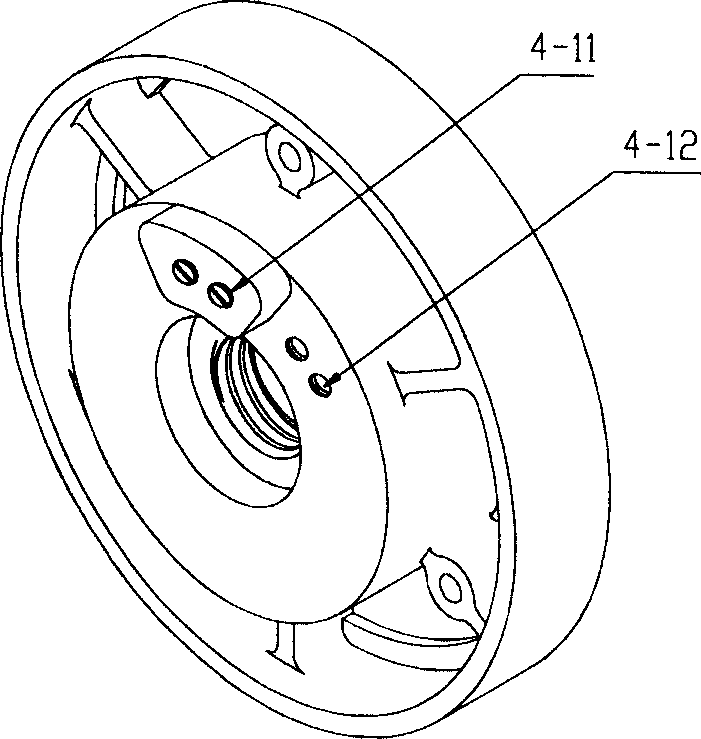

[0020] (see figure 1 ) an inertial rotation axial braking device for a garden tool, which is composed of a working shaft 7 for installing a tool, a driven wheel 4, a housing 17 and a brake block, the working shaft 7 for installing a tool is connected to the housing 17 in rotation, braking The block is located on the shell 17, the working shaft 7 is threaded 7-4 with the driven wheel 4, the outer end face of the driven wheel 4 is provided with a protrusion 4-1, the working shaft 7 is fixedly provided with a dial 5 and is arranged on The rotation plane of dial member 5 can be positioned within the height range of protrusion 4-1. In this embodiment, the brake block is composed of movable pin 13, limit pin 14, spring 15 and movable pin seat 18. The movable pin seat 18 Set on the casing 17, the movable pin 13 and the spring 15 are arranged in the movable pin seat 18, the spring 15 is arranged between the movable pin 13 and the bottom of the movable pin seat 18, and a limit sliding ...

Embodiment 2

[0022] (see figure 1 ) an inertial rotation axial braking device for a garden tool, which is composed of a working shaft 7 for installing a tool, a driven wheel 4, a housing 17 and a brake block, the working shaft 7 for installing a tool is connected to the housing 17 in rotation, braking The block is located on the shell 17, the working shaft 7 is threaded 7-4 with the driven wheel 4, the outer end face of the driven wheel 4 is provided with a protrusion 4-1, the working shaft 7 is fixedly provided with a dial 5 and is arranged on The rotation plane of dial member 5 can be positioned within the height range of protrusion 4-1. In this embodiment, the brake block is composed of movable pin 13, limit pin 14, spring 15 and movable pin seat 18. The movable pin seat 18 Set on the casing 17, the movable pin 13 and the spring 15 are arranged in the movable pin seat 18, the spring 15 is arranged between the movable pin 13 and the bottom of the movable pin seat 18, and a limit sliding ...

Embodiment 3

[0024] (see figure 1 ) an inertial rotation axial braking device for a garden tool, which is composed of a working shaft 7 for installing a tool, a driven wheel 4, a housing 17 and a brake block, the working shaft 7 for installing a tool is connected to the housing 17 in rotation, braking The block is located on the shell 17, the working shaft 7 is threaded 7-4 with the driven wheel 4, the outer end face of the driven wheel 4 is provided with a protrusion 4-1, the working shaft 7 is fixedly provided with a dial 5 and is arranged on Can make the rotation plane of dial piece 5 be positioned at the position within the height range of protrusion 4-1, in the present embodiment, (referring to Figure 7 ) The brake block adopts a friction plate 12 and the friction plate 12 is arranged on the end face of the driven wheel 4 opposite to the movable pin 13, and a reed 19 is provided on the housing 17 and the reed 19 is located at a position where it can overlap with the friction plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com