Device on spinning pre-processor for example a tufted pile feeding machine with a feeding apparatus

A technology of feeding device and feeding machine, which is applied in the direction of fiber processing, deburring device, fiber opening and cleaning machine, etc., can solve the problems of fiber material tension relaxation and error, and achieve the effect of trouble-free operation and leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

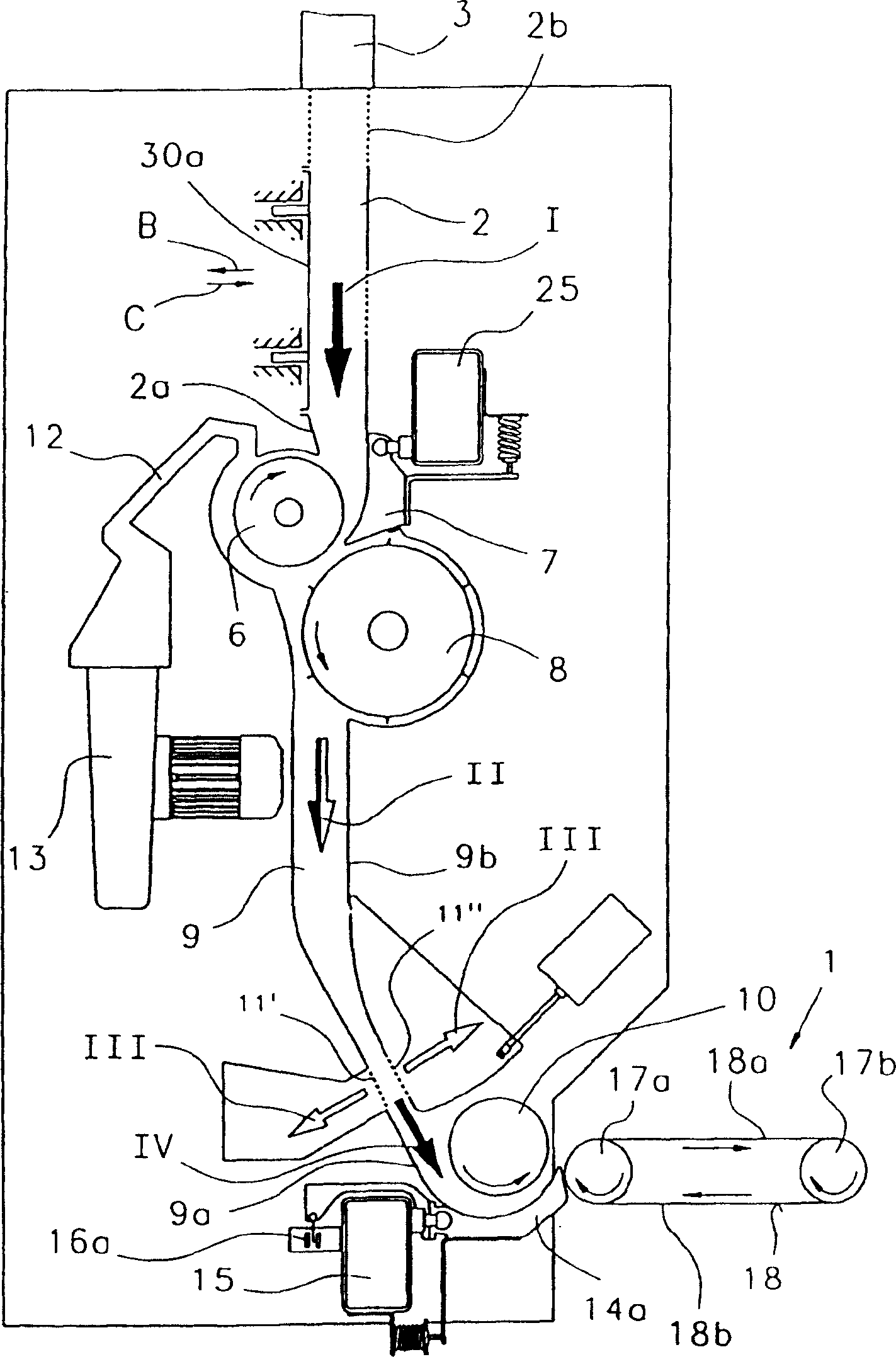

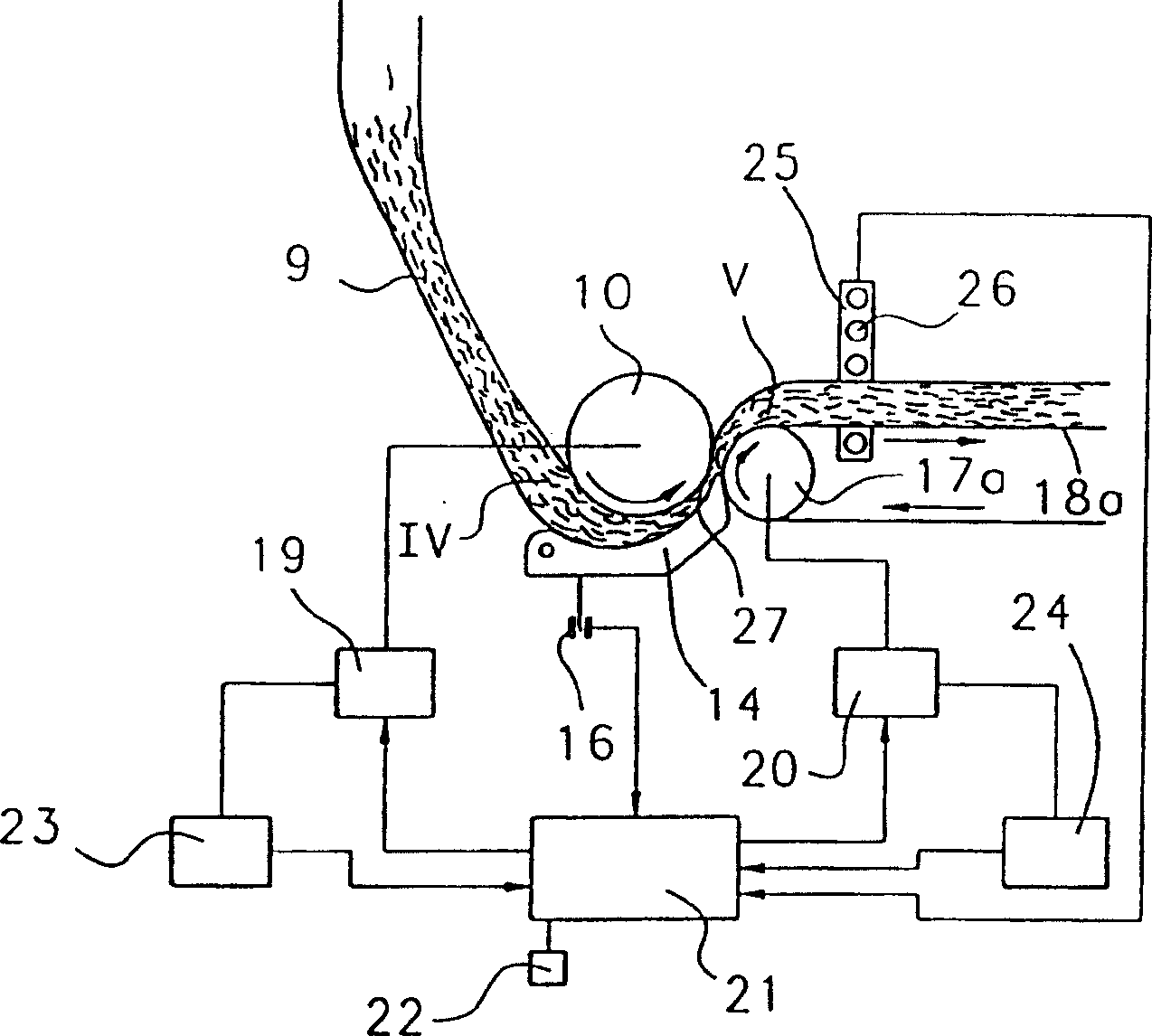

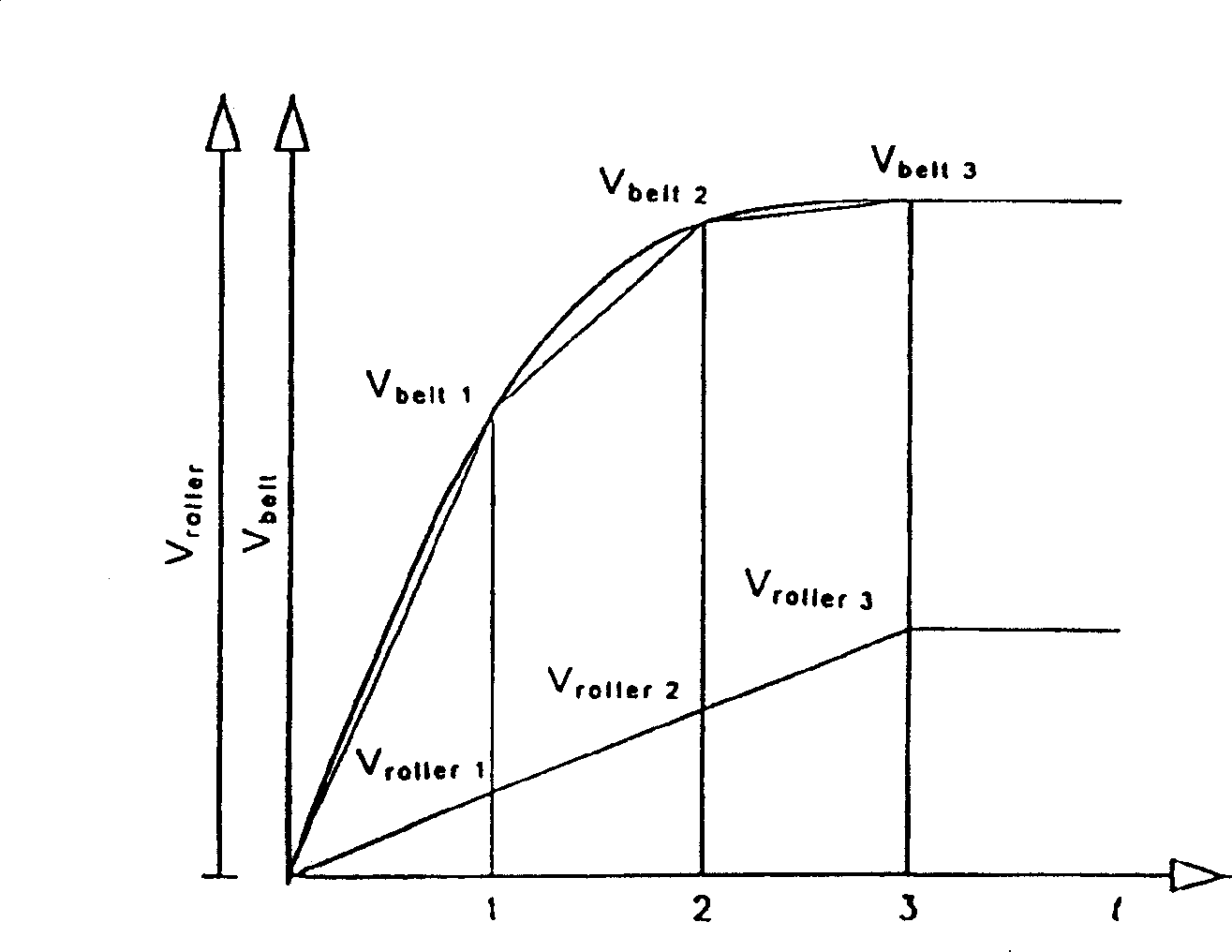

[0011] Such as figure 1 As shown, upstream of the continuously circulating conveyor belt 1 there is arranged a vertical storage tank 2 which is filled with finely opened fibrous material from above. Filling can take place, for example, via the supply and distribution line 3 by means of a collector. In the upper region of the storage tank 2 there is an air outlet 4 through which the conveying air, after being separated from the lint I, is passed into an extraction device. The lower end of the storage tank 2 is closed by an input roller 6 cooperating with an input disc 7 . Via this low-speed feed roller 6, the fibrous material can be fed from the storage tank 2 to a high-speed opening roller 8 located under the storage tank and covered with needles 8b or sawtooth wires (wire), said opening roller 8 at Part of its circumference is connected with a feed trough 9 below. The opening roller 8 rotates in the direction of the arrow 8a to convey the fibrous material III it collects i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com