Photoacoustic gas sensor, and a method for its production

A gas sensor, photoacoustic technology, applied in printed circuit parts, material analysis by optical means, material analysis using acoustic/ultrasonic/infrasonic waves, etc. energy and other issues, to achieve the effect of small size, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

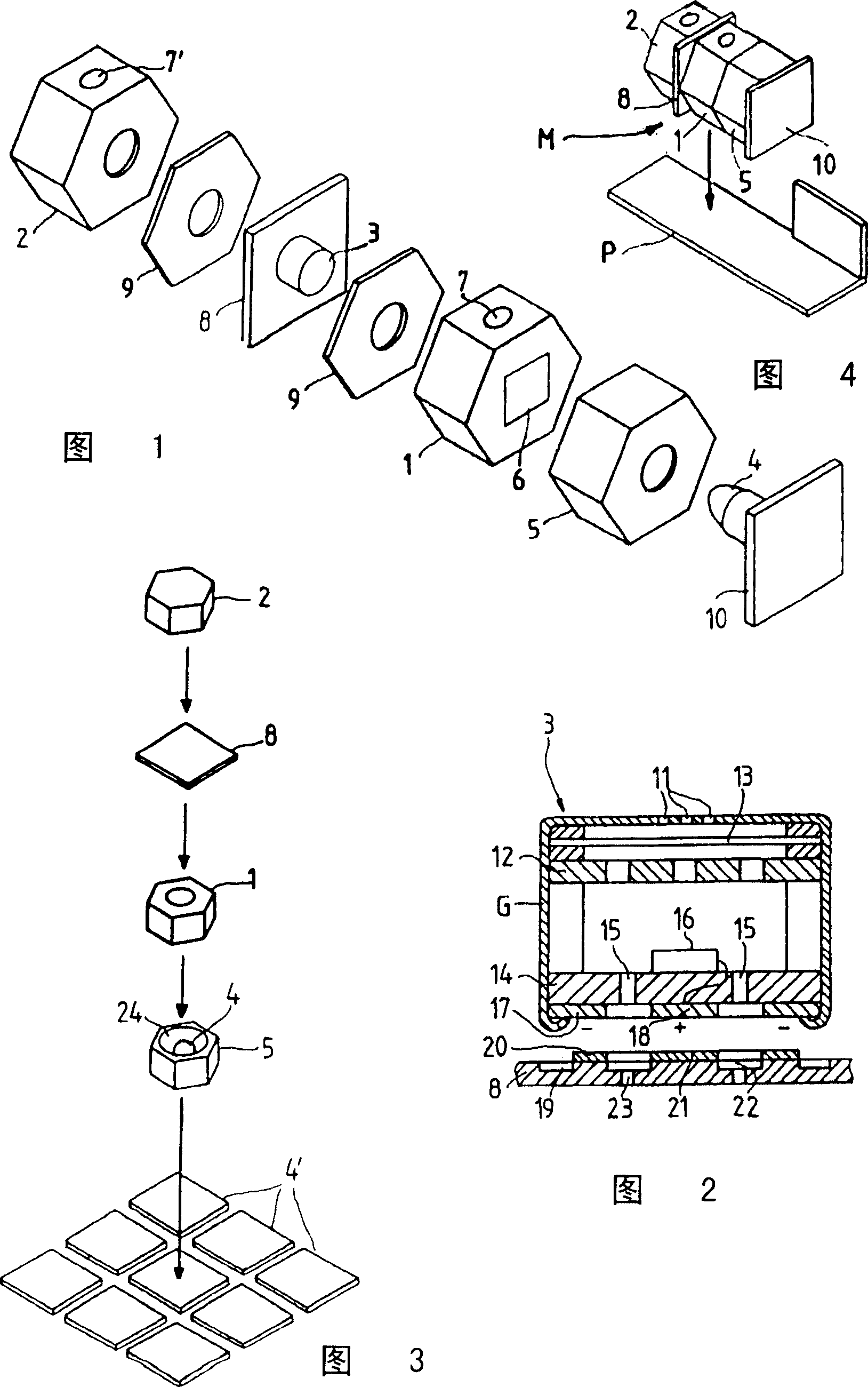

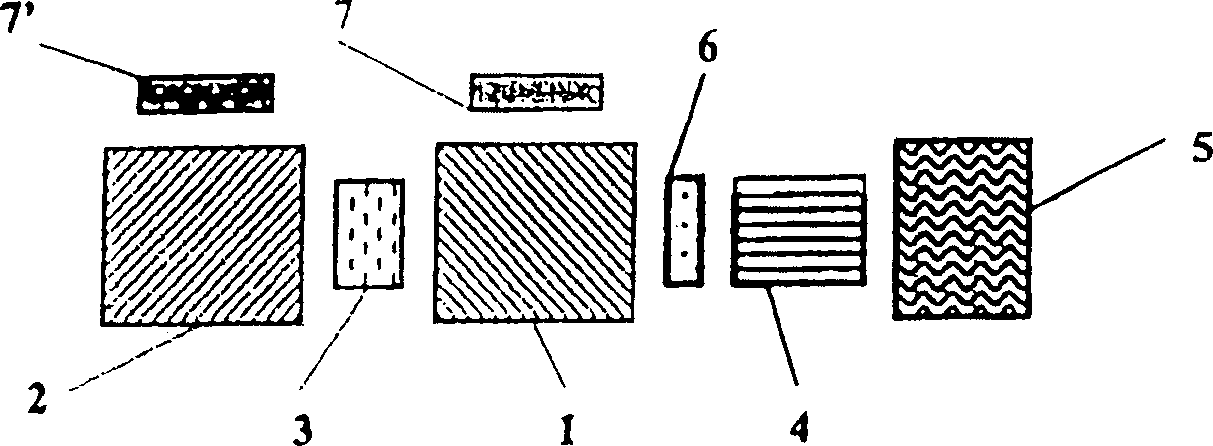

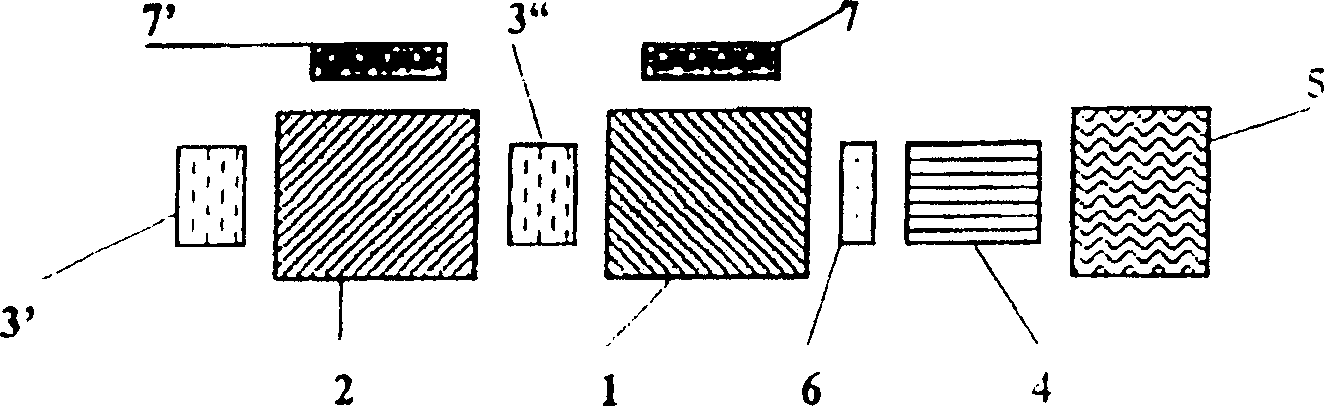

[0021] The acousto-optic gas sensor shown in Figure 1 includes a measuring element 1, a reference element 2, a two-way differential microphone 3 arranged between the two elements 1 and 2, a miniature incandescent lamp corresponding to the measuring element 1 4 and a reflector housing 5 with a reflector, wherein the reflector is used to focus the light emitted by the miniature incandescent lamp 4 onto a window arranged on the side wall of the measuring element 1 facing the miniature incandescent lamp 4, an infrared A bandpass filter 6 is inserted in this window. Measuring element 1 and reference element 2 are absolutely identical in terms of their design and dimensions. Both the measuring cell 1 and the reference cell 2 are provided with a window on an outer side wall, into which a gas-permeable membrane 7 or 7', respectively, is inserted. The differential microphone 3 is mounted on a printed circuit board 8 and a seal 9 is (optionally) provided on each of the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com