Aqueous organosilicon leather smoothing and clearing agent and its preparation

A slip agent and silicone technology, which is applied in the field of water-based silicone leather slip agent and its preparation, can solve the problems of insufficient leather feel, and achieve the effect of improving the stability of the emulsion and the waterproof performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

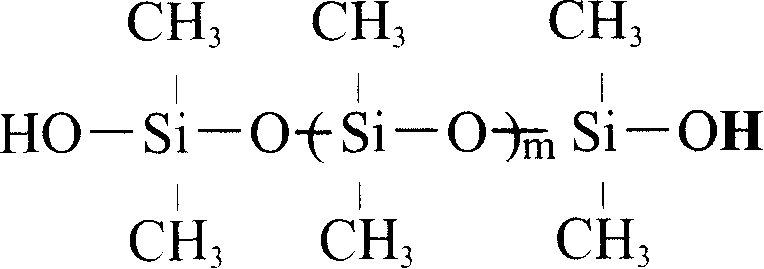

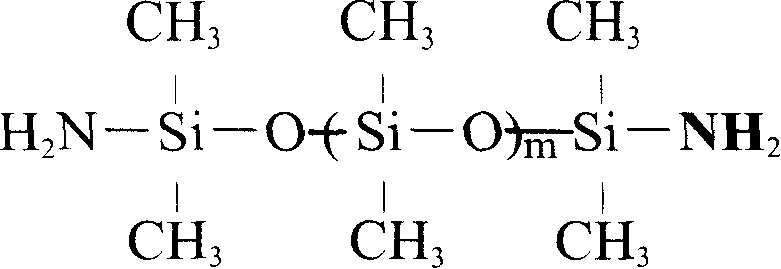

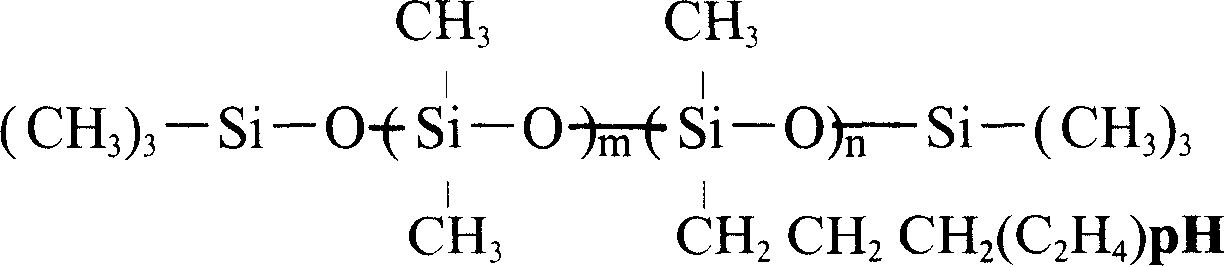

Method used

Image

Examples

Embodiment 1

[0029] Put 15 kg of organosilicon hydroxy silicone oil, 15 kg of organosilicon amino silicone oil and 11 kg of organosilicon polyether modified silicone oil into the reaction kettle, then add 0.2 kg of organic acid catalyst, and catalyze the polymerization reaction at a temperature of 15-30°C for 3 hours. Then add 0.5 kg of additives and react for 1 hour, finally add 184 kg of deionized water to emulsify for 5 hours, filter and pack.

[0030] Some performance indicators of the resulting product are:

[0031] Active ingredient ≤18.0%

[0032] PH value ≥4.0

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap