Apparatus and method for measuring conducting fluid density

A technology for conducting fluids and measuring devices, which is applied in the fields of measuring devices, electrochemical variables of materials, and material analysis by electromagnetic means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

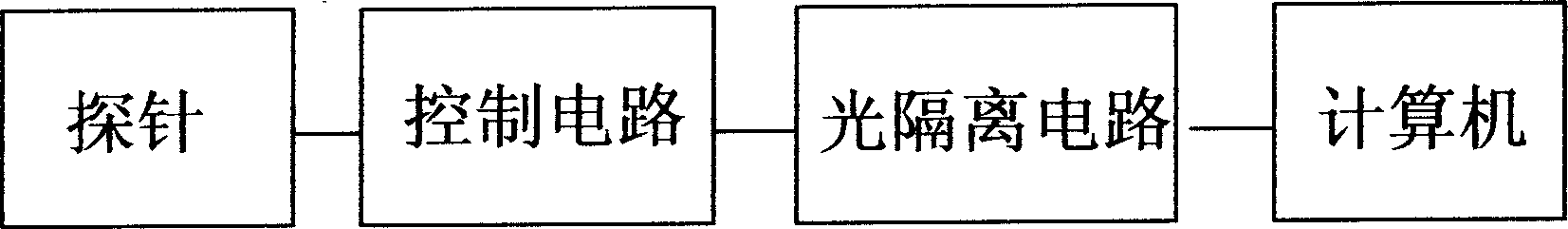

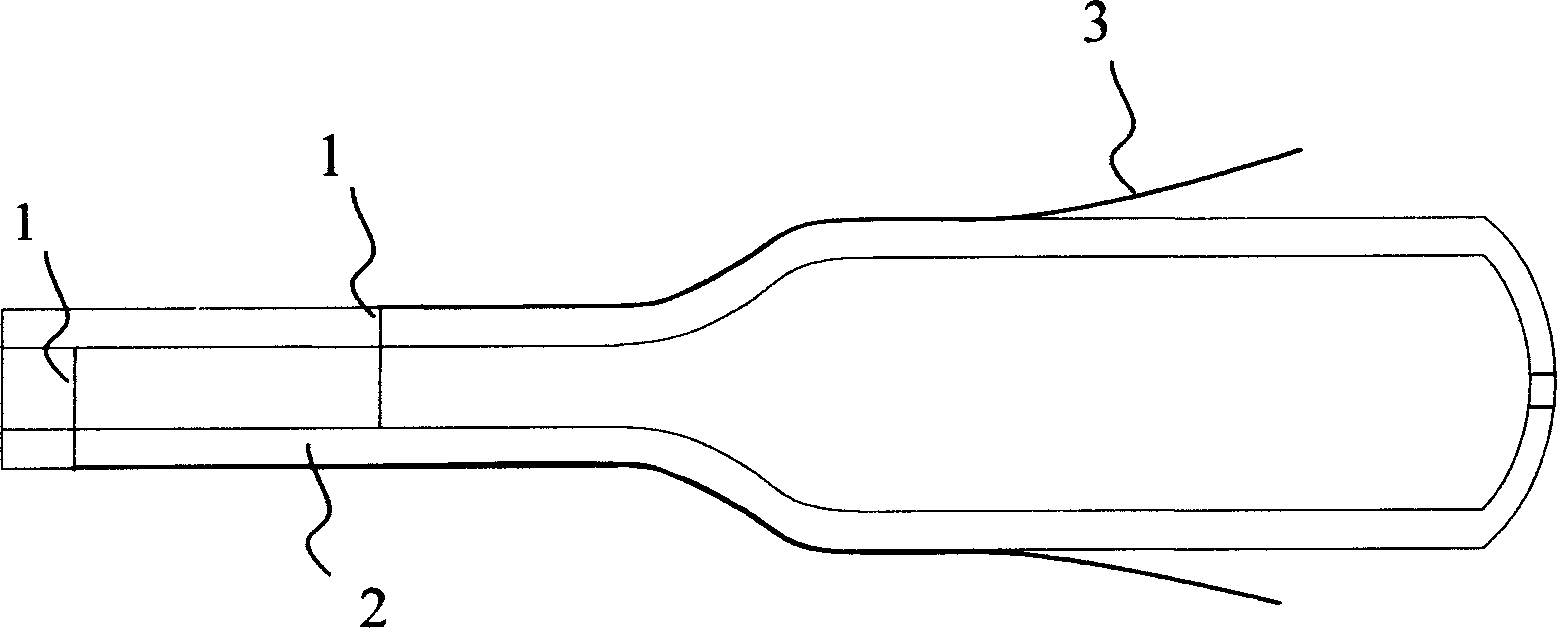

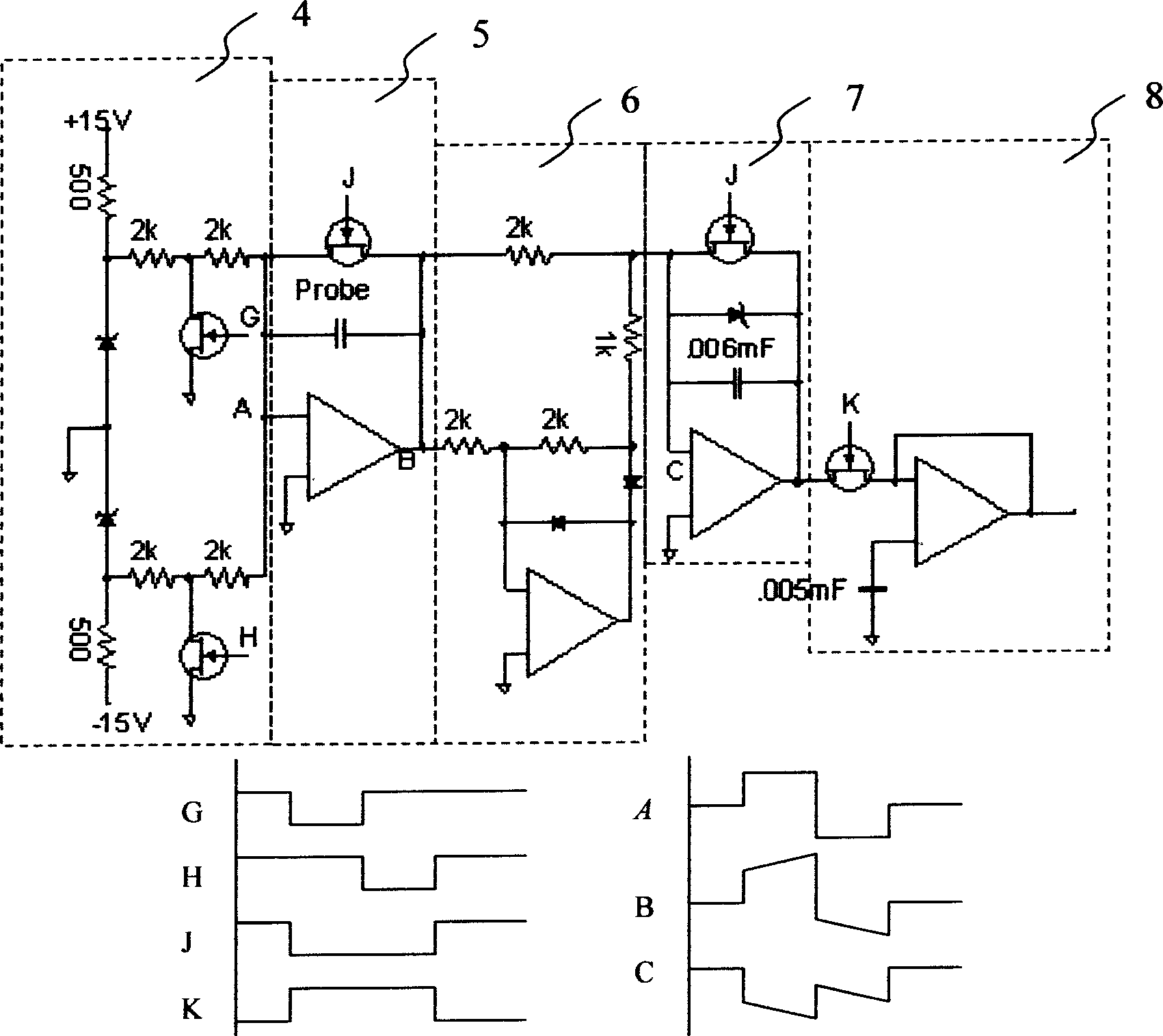

[0017] Such as figure 1 As shown, the device for measuring the density of conductive fluid of the present invention includes: a probe, a control circuit, the probe is connected to the control circuit in turn, an isolation circuit composed of a 4N25 photoelectric coupling element, and a computer. In order to effectively isolate the influence of the surrounding fluid on the measurement, the present invention designs a special sampling probe, such as figure 2 shown. The probe is made of an insulating (plastic and glass) thin tube 2 with an outer diameter of 1.6 mm. The outer diameter of the head is shrunk to about 1.0 mm by stretching. The purpose is to facilitate fixing, and the inner diameter is about 0.5 mm. Electrode 1 uses two platinum wires with a diameter of 0.13mm, which are inserted into the capillary tube transversely with a distance of about 12.7mm, and the distance between the first platinum wire and the probe head is about 3.2mm. The lead wire 3 from the electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com