Mine water sump duff fluid automatic cleaning and treating method and apparatus

A technology for processing equipment and mine water, applied in mining equipment, drainage, earth-moving drilling, etc., can solve the problems of unsuitable excavation of fine coal-slurry-water mixture in mine water silo, harsh working environment, and pollution of mine environment, so as to achieve equipment selection. Reasonable layout, solving heavy labor, and improving the effect of recycling and stacking environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

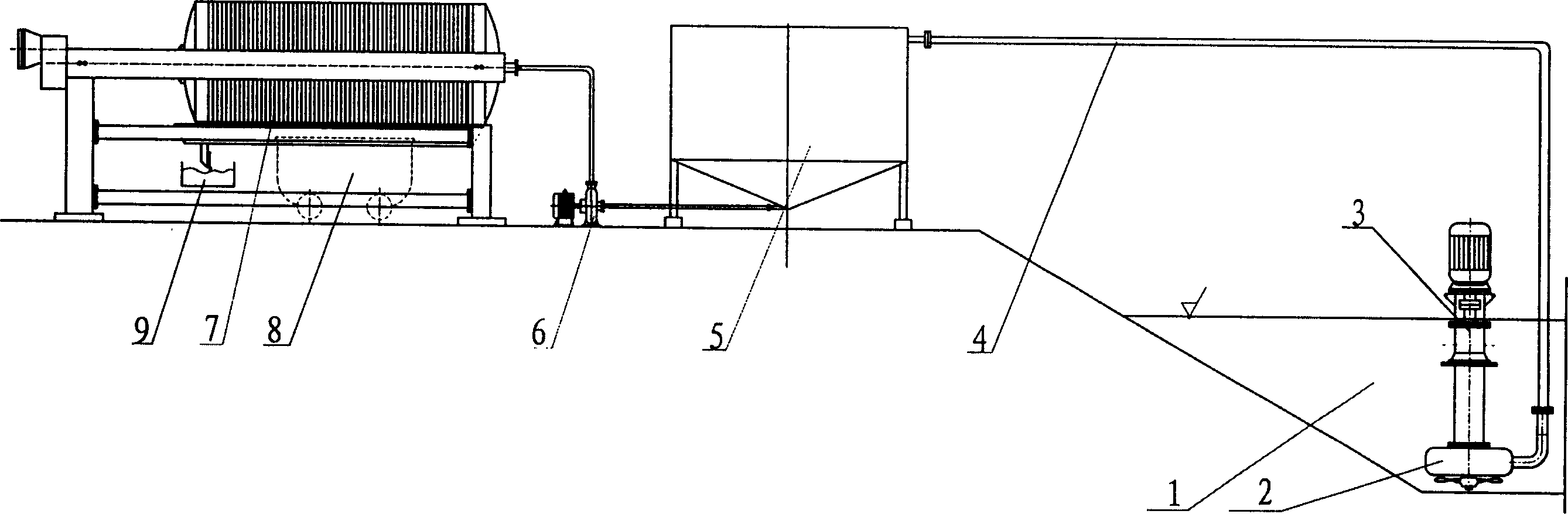

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0010] The steps of the mine water tank fine coal slime automatic clearing and excavation processing method of the present invention are as follows:

[0011] Step 1: Start the switch, the pumping device 3 and the agitator 2 set in the mine water tank 1 start to work, the agitator 2 first stirs the deposited coal slime to mix it with water to facilitate the self-priming pumping device 3 suction, the fine coal slime water mixture is sent into the buffer device 5 through the slurry discharge pipe 4;

[0012] Step 2: The coal slime water mixture sent into the buffer device 5 is deposited in the buffer device 5 to form a stable material;

[0013] Step 3: Under the control of the start switch, the booster pump 6 installed in the outlet pipeline of the buffer device 5 is started, and the stable material in the buffer device 5 is sprayed into the dehydration devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com