Method for processing cooled meat

A processing method and technology for cooling meat, which can be used in slaughtering accessories, slaughtering, slaughtering devices, etc., can solve the problems of short freshness and shelf life, high juicing rate of cooled meat, unstable color, etc., to ensure food safety and easy to popularize. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

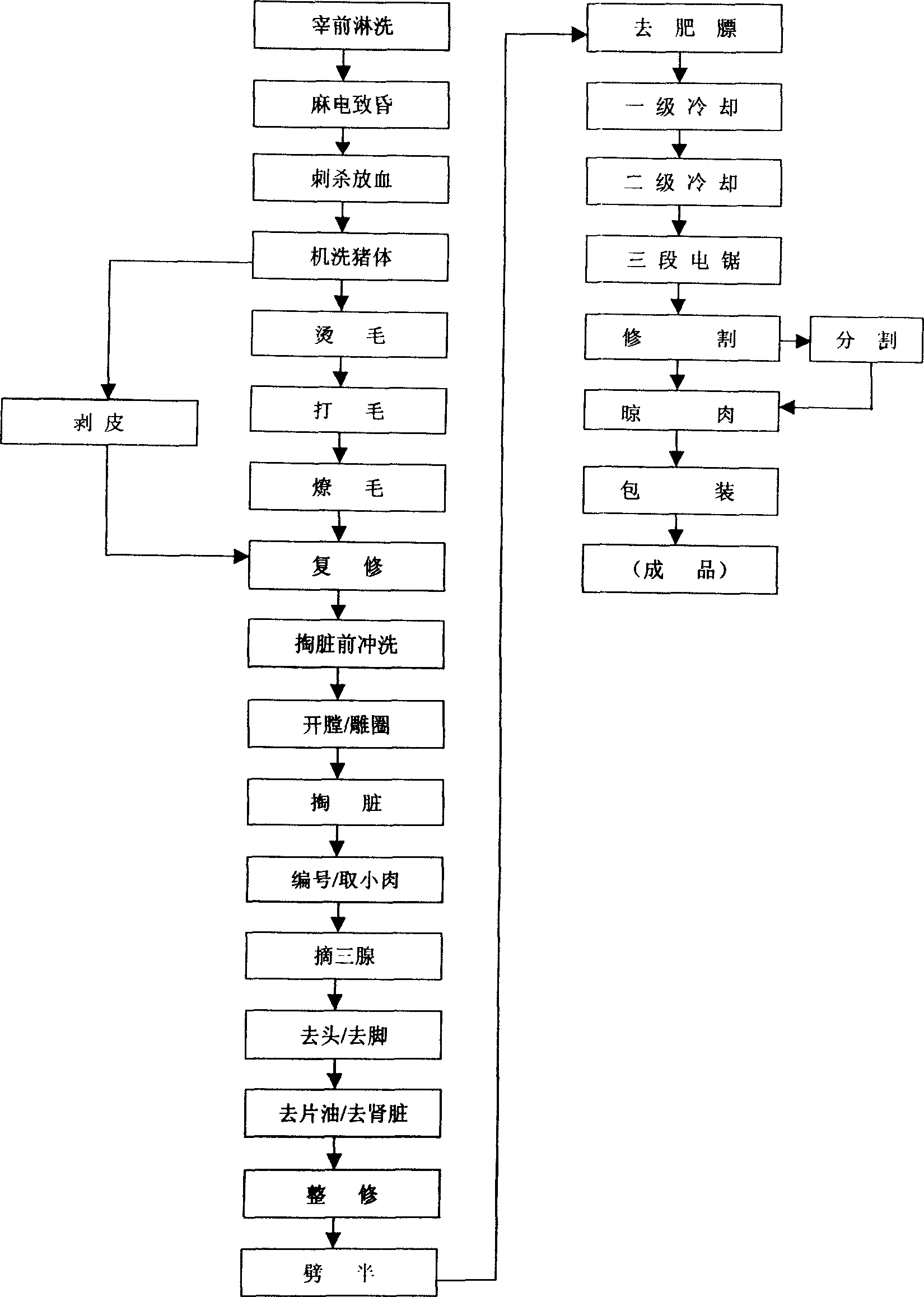

Image

Examples

Embodiment 1

[0047] Embodiment 1: Select healthy pigs and slaughter them according to the technical requirements. The whole slaughtering process must not exceed 45 minutes. The carcasses that have been slaughtered and split in half are immediately subjected to the fat removal process, and the time is controlled within 10 minutes. The temperature is at -20°C. When the deep center temperature of the carcass reaches 18-20°C, it is transferred to the secondary cooling store and the temperature is kept at 1°C, so that the deep center temperature reaches 4°C. After 26 hours after slaughter, the pork slices are subjected to third-stage cooling. Segment the chainsaw, then enter the partition room. Complete the division within 30 minutes, keep the temperature in the division room at 11°C, then put it into the meat drying room, keep the temperature at 2°C, and let it dry until the temperature of the meat center reaches 4°C. Small tray packaging, vacuum packaging and modified atmosphere packaging can...

Embodiment 2

[0048] Embodiment 2: Select healthy pigs and slaughter them according to the technical requirements. The whole slaughtering process must not exceed 45 minutes. The carcasses that have been slaughtered and split in half are immediately subjected to a fat removal process. The time is controlled within 10 minutes, and then enters the primary cooling room for storage The storage temperature is -18°C. When the deep center temperature of the carcass reaches 18-20°C, it is transferred to the secondary cooling room and the temperature is kept at -2°C, so that the deep center temperature reaches 6°C. Make a three-section chainsaw, then enter the split room. Complete the division within 30 minutes, keep the temperature in the division room at 11°C, then enter the meat drying room, keep the temperature at 0°C, and let the meat dry until the temperature of the center of the meat reaches 3°C. Small tray packaging, vacuum packaging and modified atmosphere packaging can be carried out accord...

Embodiment 3

[0049]Embodiment 3: Select healthy pigs and slaughter them according to the process requirements. The whole slaughtering process must not exceed 45 minutes. The carcasses that have been slaughtered and split in half are immediately subjected to a fat removal process. The time is controlled within 10 minutes, and then enters the first-level cooling store The storage temperature is -15°C. When the deep center temperature of the carcass reaches 18-20°C, it is transferred to the secondary cooling room and the temperature is kept at 0°C, so that the deep center temperature reaches 4°C. The pork slices are refrigerated 28 hours after slaughter. Three-section chainsaw, then trimming and then entering the partition room. Complete the division within 30 minutes, keep the temperature in the division room at 11°C, then put it into the meat drying room, keep the temperature at 4°C, and let it dry until the temperature of the meat center reaches 4°C. Small tray packaging, vacuum packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com