Acid washing device

A pickling equipment and pickling technology, applied in metal processing equipment, workpiece surface treatment equipment, manufacturing tools, etc., can solve the problems of reducing the quality of steel plates, reducing production efficiency, shortening the life of pickling solution, etc., to achieve high production efficiency, The effect of prolonging the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

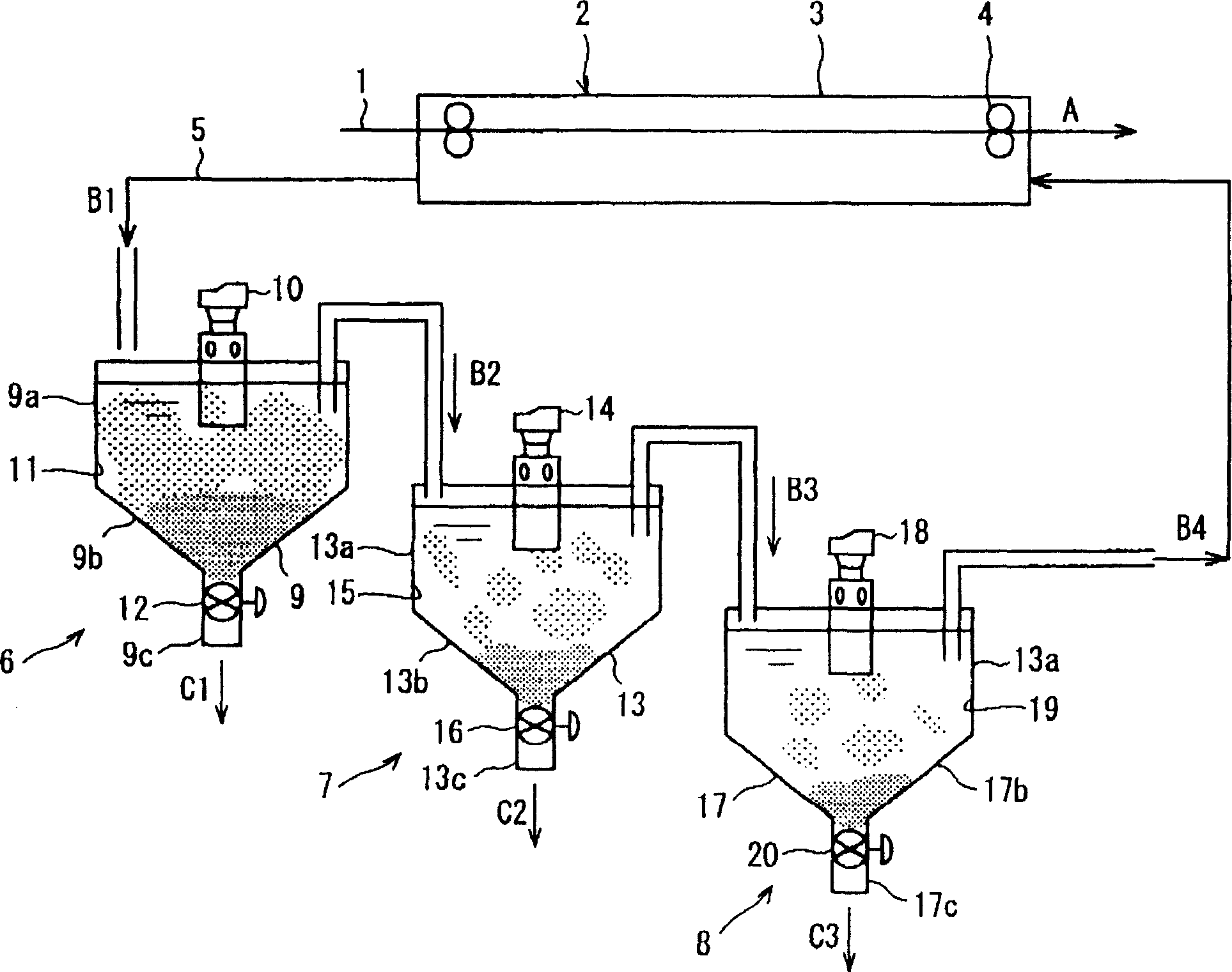

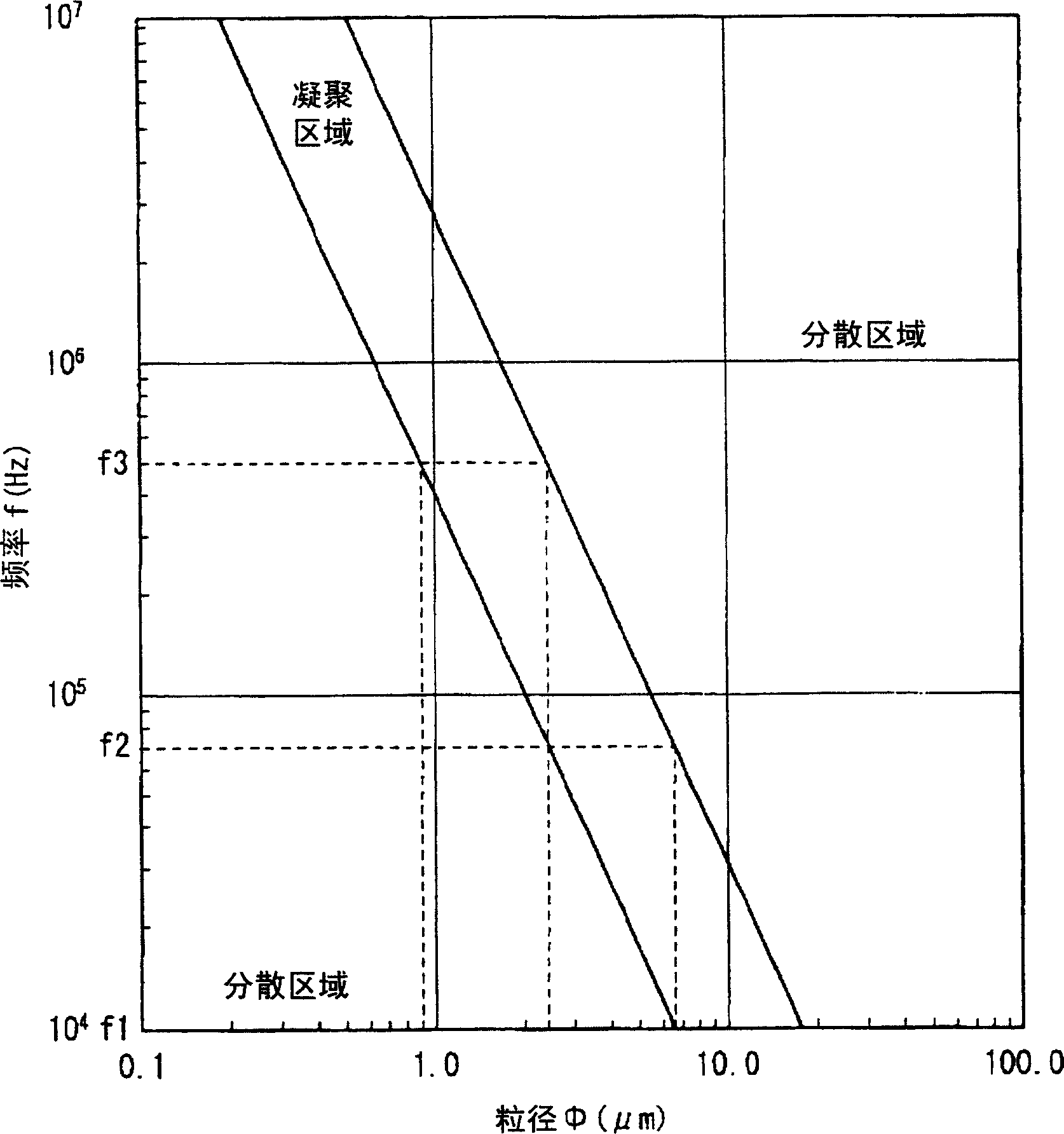

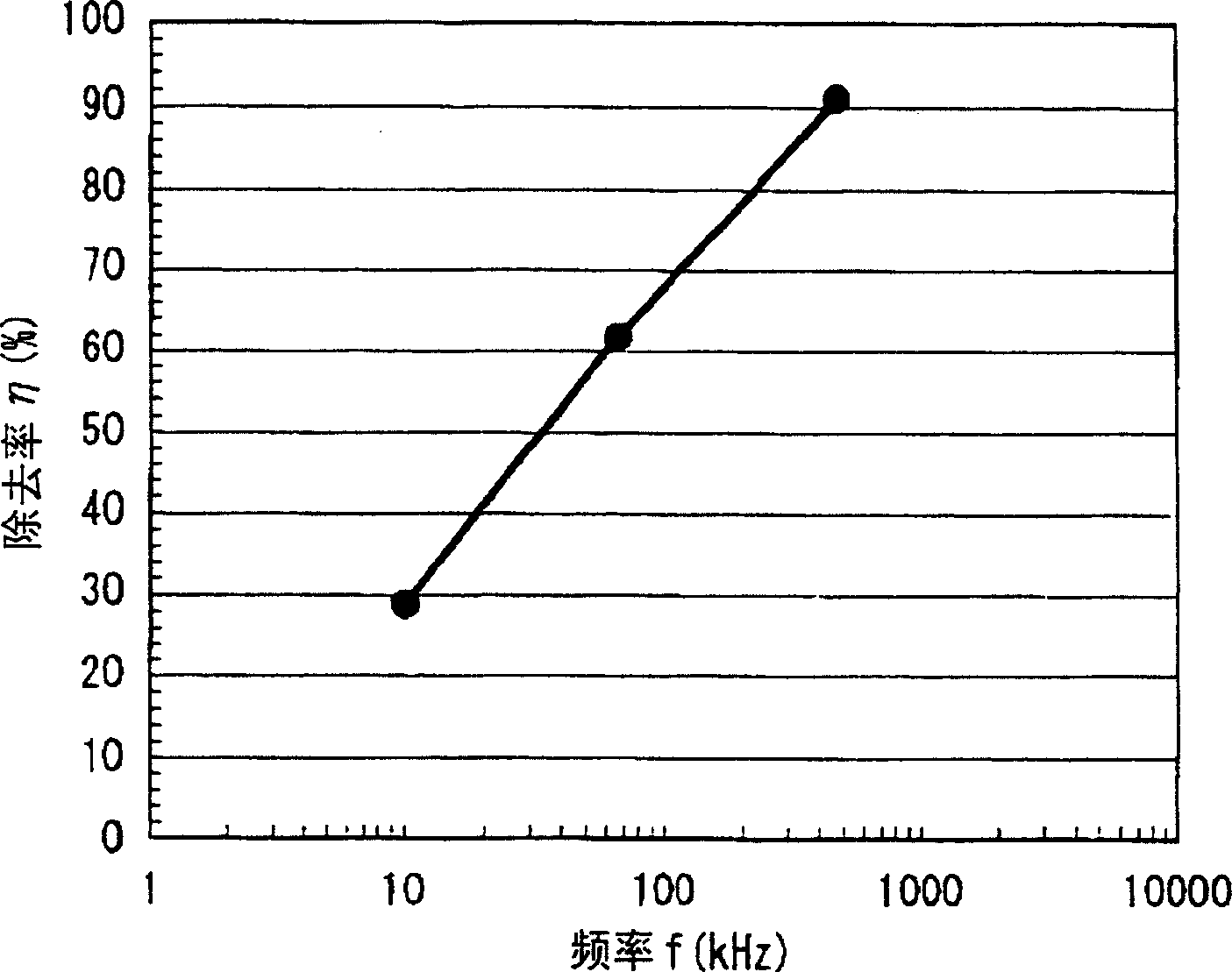

[0037] figure 1 It is a schematic diagram of the pickling facility of Example 1 of the present invention. figure 2 It is an aggregation and dispersion diagram showing the relationship between the ultrasonic frequency and the particle size of the microparticles. image 3 is the SiO in the pickling solution of Example 1 representing the present invention 2 A graph of particle removal rates.

[0038] Such as figure 1 As shown, the steel sheet 1 which is the steel sheet material containing silicon is supplied in the arrow direction A shown in the figure, and passes through the inside of the steel sheet pickling device 2 . The steel plate pickling device 2 includes a pickling tank 3 for storing pickling liquid for pickling the steel plate 1, and a drum 4 for cutting the pickling liquid. The pickling tank 3 communicates with a circulation path 5 for circulating a pickling liquid, and the pickling liquid flows in the circulation path 5 in a direction opposite to the supply direc...

Embodiment 2

[0064] Figure 4 It is a perspective view of the separation device of Example 2 of the present invention. Arrows B5 and B6 in the figure indicate the flow of pickling solution.

[0065] Figure 4 The separation device 21 shown is because it is described in the embodiment 1 figure 1 The separators 6 , 7 , and 8 disposed on the circulation path 5 of the pickling facility shown are changed and installed, so descriptions of the same symbols or symbols are omitted.

[0066] Separation device 21 is equipped with for separating SiO from pickling solution 2 The separation tank 22 for particles, the ultrasonic vibrator 23 that emits an ultrasonic wave with a frequency f1 immersed in the pickling solution stored in the separation tank 22, the ultrasonic vibrator 24 that emits an ultrasonic wave with a frequency f2, and the ultrasonic vibrator that emits an ultrasonic wave with a frequency f3 25 and reflection plates 26, 27, 28 provided so as to face these ultrasonic vibrators 23, 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com