Method for simultaneously measuring bending curvature and bending direction

A technology of bending direction and measurement method, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that have not been discovered and can not realize the discrimination, and achieve the effect of low cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical solution of the present invention, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

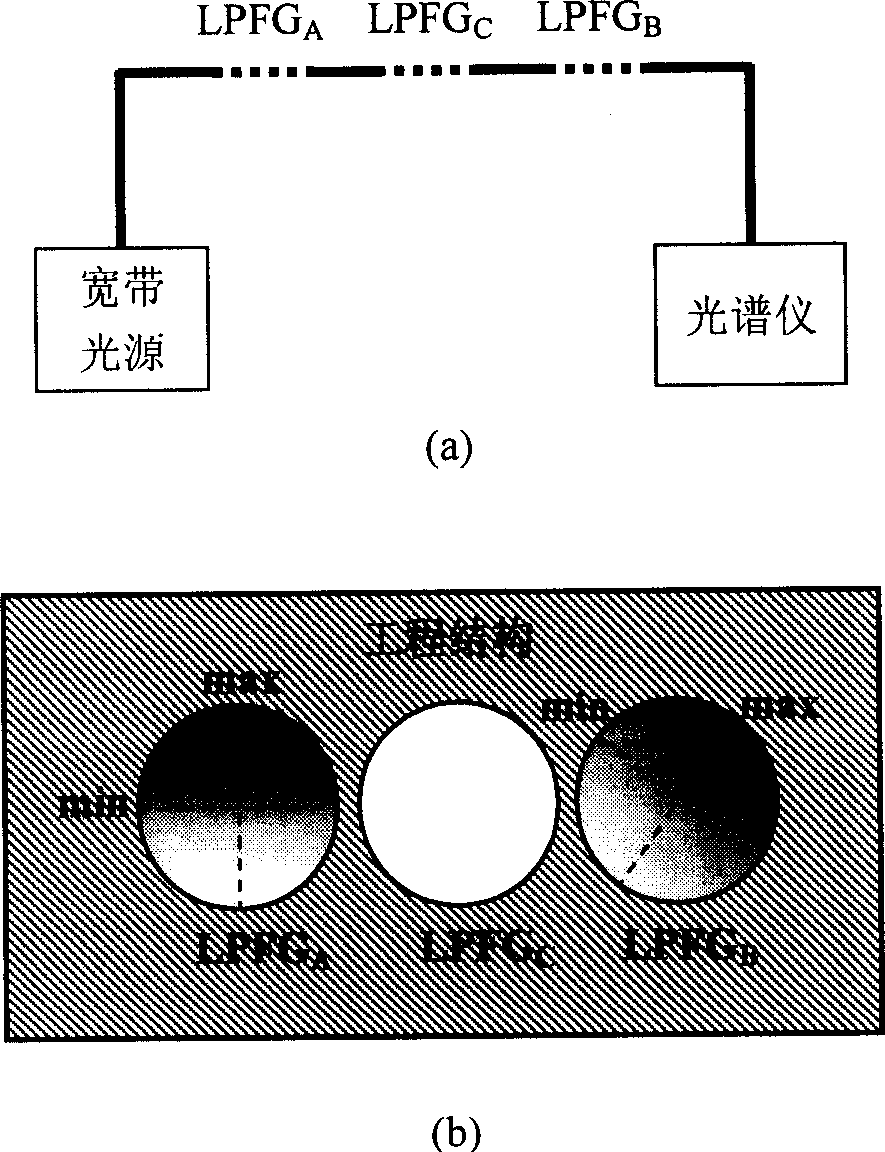

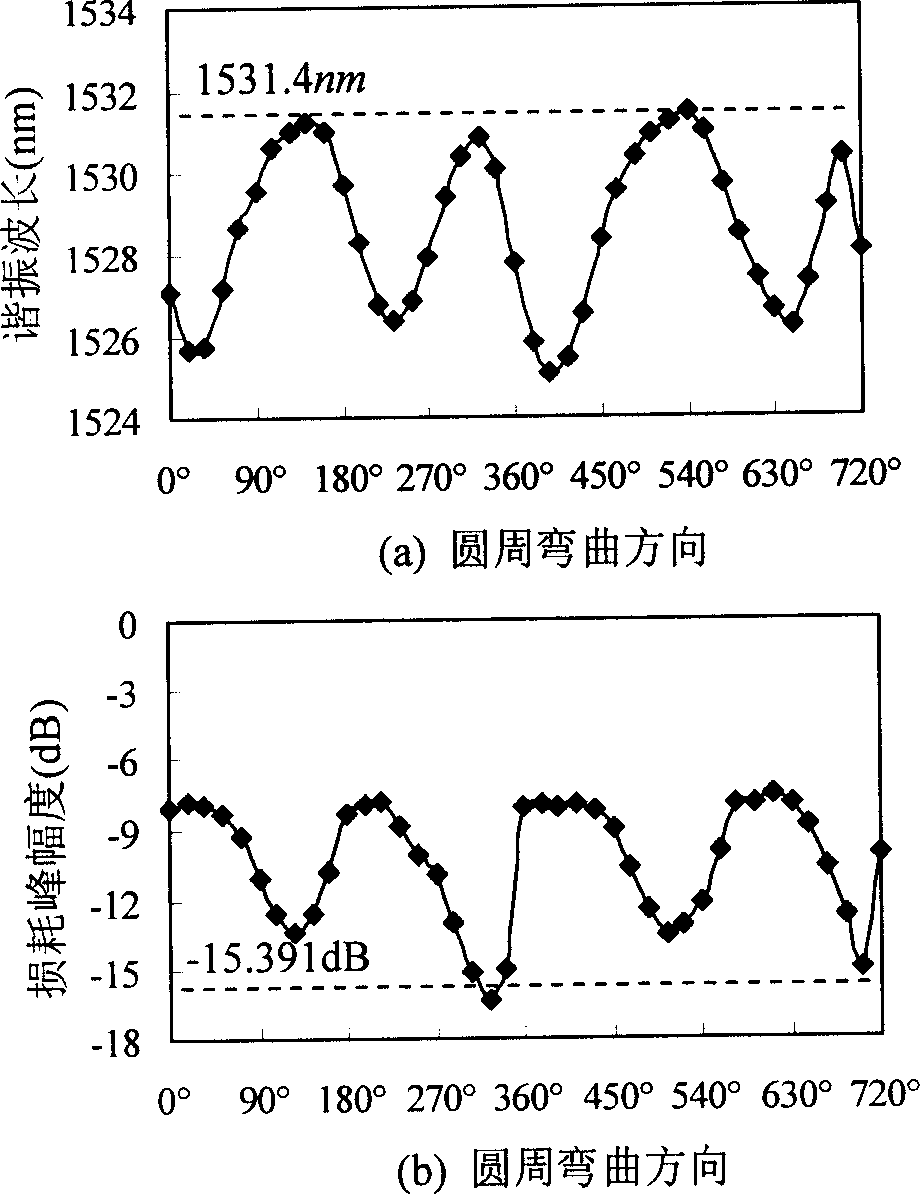

[0027] The principle diagram of the simultaneous measurement method of bending curvature and bending direction proposed by the present invention is as follows figure 1 shown. The scheme is mainly based on the high frequency CO 2 The bending characteristics of long-period fiber gratings written by laser pulses have obvious bending direction dependence. The measurement steps of the specific example are as follows:

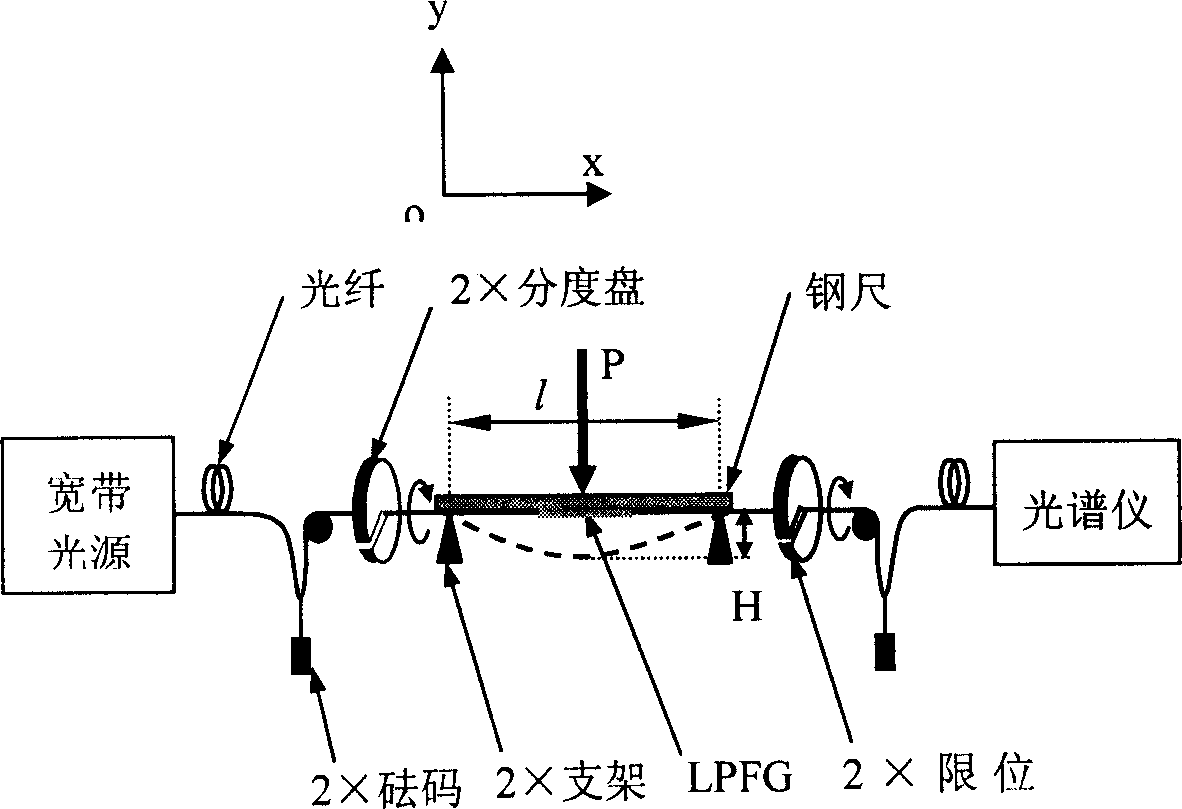

[0028] (1) use figure 2 The shown bending characteristic measurement device measures the bending sensitivity of the resonant wavelength and loss peak amplitude of the LPFG to bending in different directions. LPFG represents the measured long-period fiber grating; P represents the applied pressure; l represents the length of the bent optical fiber (grating), that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com