Spun-bonded nonwoven fabric and sanitary supplies

A technology for sanitary materials and non-woven fabrics, which is applied in non-woven fabrics, textiles and papermaking, medical science, etc., can solve the problem of not disclosing the effect of improving the adhesion of melt-blown fiber webs, and achieve the effect of soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 Embodiment 2

[0117] Using titanium oxide-containing polypropylene (MFR = 40 measured under the conditions of Table 1 of JIS-K7210) as a raw material, long fibers melted and extruded from a nozzle with a circular cross-section are cooled from the side near the spinneret while using Traction and pulling devices such as air aspirators are used for traction. The filaments coming out of the pulling device are opened by the charging device, and then collected as a net on the moving metal mesh conveyor.

[0118] The web is passed between the embossing rolls / flat rolls heated to 135°C, and a needle point pattern (area ratio of about 7%) arranged in a zigzag pattern (area ratio of about 7%) is formed in a circle with a diameter of 0.43 mm and an inclination of 45° and an inclination pitch of 1.5 mm. Heat press welding, thus obtaining a non-woven fabric with scattered patterns of pinpoints.

[0119] The constituent fibers of the obtained spunbonded nonwoven fabric are circular cross-section filamen...

Embodiment 3、 Embodiment 4

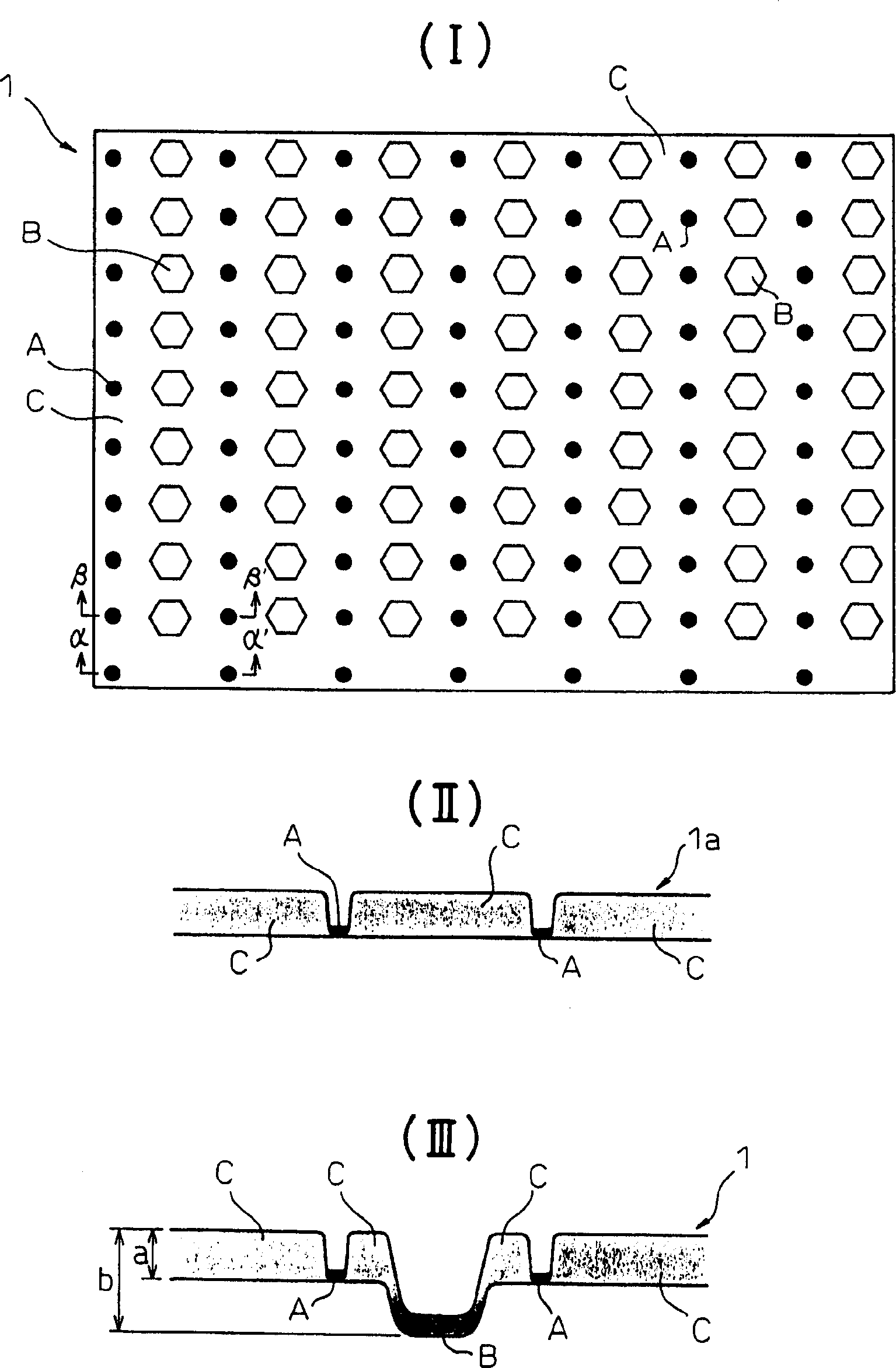

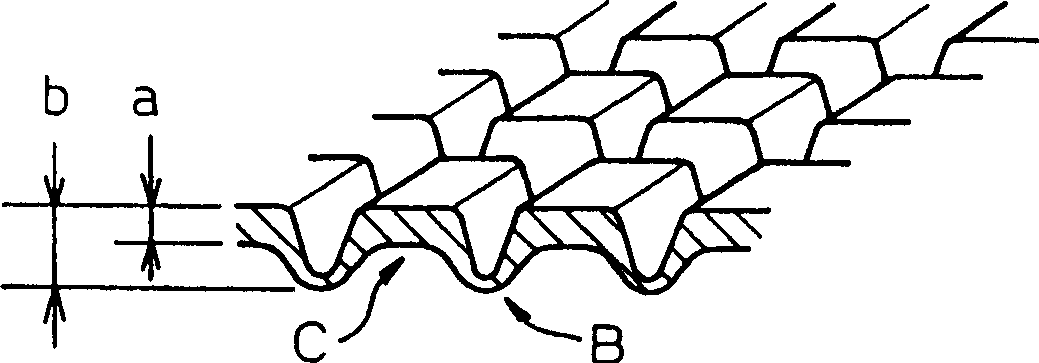

[0124] Except that the non-combining down-pressing embossing pattern is discontinuous as the opposite of embodiment 1 as the raised tortoise shell pattern (0.45mm on one side, 25% of the pressing area ratio, pattern spacing vertically 2.8mm, horizontally 3.2mm, deep 0.6mm), other are all identical with embodiment 1, thereby obtain 2.8dtex, the weight per unit area is 20g / m 2 The non-woven fabric of the present invention. The evaluation results of non-woven fabrics are shown in Tables 1 and 2.

[0125] The nonwoven fabric was used as the surface layer, and in Example 3, the continuous protrusions of the low-density region of the nonwoven fabric (the surface of the nonwoven fabric) were used on the skin side of the surface layer, and in Example 4, the nonwoven fabric was used instead. The non-continuous debossed pattern surface of the high-density area on the back is used for the top layer to make disposable diapers. As in the Examples, the softness was better than that of the...

Embodiment 5

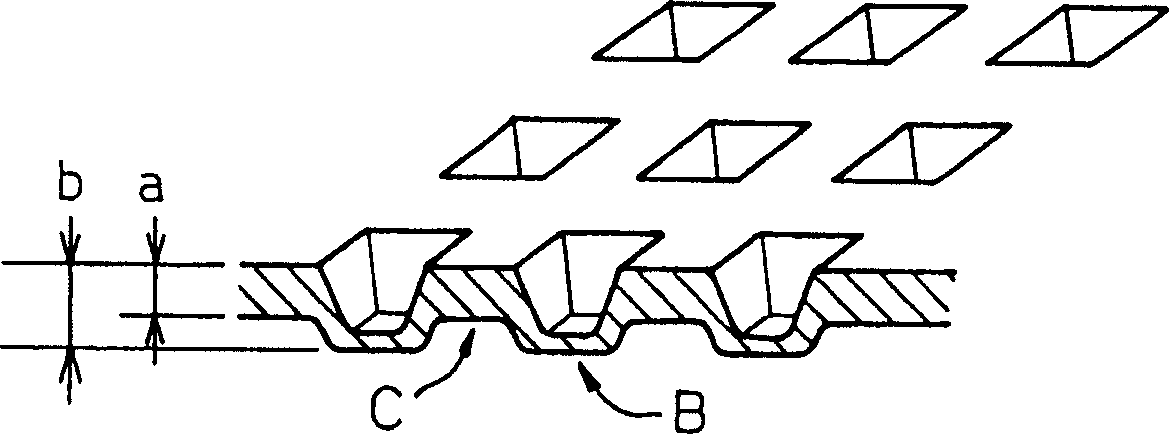

[0127] Except for the non-combined embossed pattern as a discontinuously scattered concave grid pattern (0.3mm×0.7mm on one side, 22% pressing area ratio, 0.6mm deep) and passing through a roller containing a concave grid pattern that matches the pattern Except combination place, other are all identical with embodiment 1, thereby obtain 2.0dtex, the weight per unit area is 18g / m 2 The non-woven fabric of the present invention. The evaluation results of non-woven fabrics are shown in Tables 1 and 2.

[0128] A disposable diaper was produced by making the surface of the nonwoven fabric with the continuously raised surface of the low-density region (the surface of the nonwoven fabric) facing the skin surface of the top layer. Like Example 1, compared with the conventional nonwoven fabric, it is better in softness and has good rewetting performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com