High corrosion resisting and high wearable non-crystalline iron based nano crystal cost for plasma spraying and preparation method

An iron-based amorphous and plasma technology, applied in the direction of coating, metal material coating process, etc., to achieve excellent comprehensive performance of corrosion resistance and wear resistance, and improve the effect of cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The composition of the selected iron-based multi-element amorphous alloy powder is calculated by weight percentage: 0.9%wtC, 3.8%wtSi, 4.1%wtB, 6.5%wtCr, 11.5%wtW, 6.7%wtMo, 4.5% %wtNi, 0.2%wt Y, the rest is Fe, and the particle size of the powder ranges from 160 mesh to 400 mesh. The coating was prepared on the 0Cr13Ni5Mo stainless steel substrate by plasma spraying. The plasma spraying parameters were: arc voltage 60V, arc current 550A, main gas (Ar gas) 60L / min, auxiliary gas (H 2 Gas) 30L / min, powder feeding speed 45g / min, spraying distance 120mm. During the spraying process, the substrate is cooled by air blowing method, and the flow rate of the cooling gas is 300 L / min.

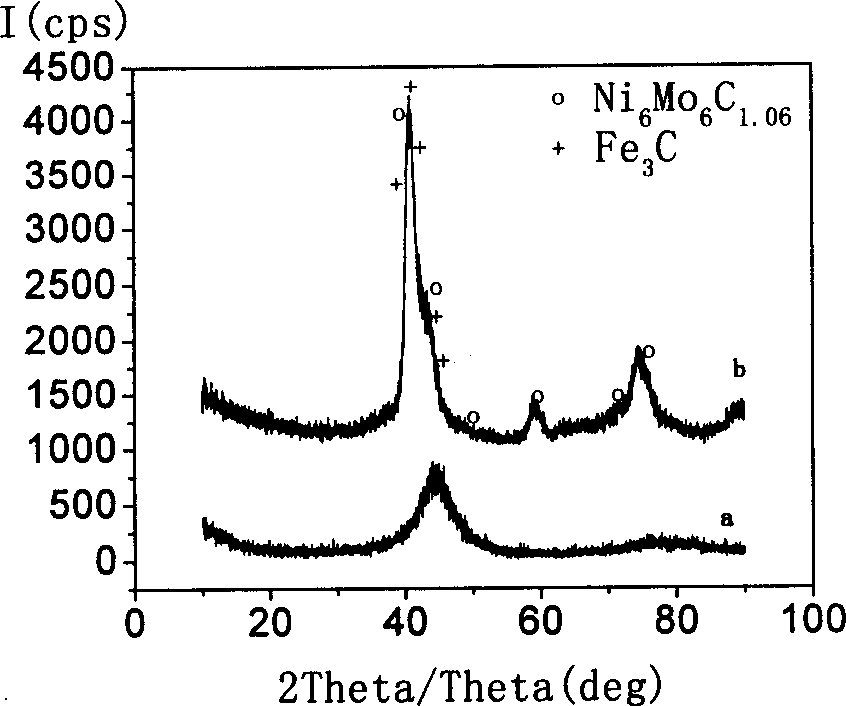

[0018] Crystal structure of spray powders and coatings

[0019] figure 1 It is the X-ray diffraction pattern of the iron-based spray powder and the corresponding coating. It can be seen from the figure that the spray powder is a typical amorphous powder, and the coating contains crystalline su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com