Finishing agent for anti flokkit and balling up for woolen sweater

An anti-pilling and finishing agent technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of unsatisfactory color retention of woolen sweaters, acid and alkali resistance of woolen sweaters, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

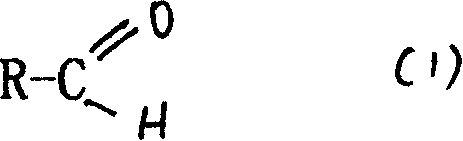

Method used

Image

Examples

Embodiment 1

[0013] Select this white cashmere fabric to carry out the test, woolen sweater cleaning pretreatment, reduction pretreatment, washing, centrifugal dehydration, soaking treatment with finishing liquid formaldehyde, drying, cleaning, centrifugal dehydration, softener solution impregnation, centrifugal dehydration, softening Liquid impregnation, centrifugal dehydration, drying. The anti-pilling grade of the fabric after finishing as above can reach above grade 3.5, while the ordinary treated sample without anti-pilling finishing has only grade 2.0.

example 2

[0015] 56 pieces of this white wool fabric were selected for testing, and the anti-pilling finishing of the fabric was carried out according to the above-mentioned implementation method and finishing process. The finishing agent was glyoxal. The ordinary treatment sample of anti-pilling finishing is only 2.0 grade.

[0016] Selecting wool fabrics of different colors and repeating the test, the anti-pilling level of the finished fabrics can reach above 3.5, and the color is very close to the original, with soft, smooth, and good elasticity.

example 3

[0018] Select 56 wool fabrics to test. Malondialdehyde is used as a finishing agent, and the test results have confirmed that when the amount of finishing agent is increased by 0.5 to 1.0 times compared with the general amount, the anti-pilling level can be increased to above 4.0. And the color has no obvious change, and the hand feels soft, smooth and elastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com