Spray type dust separator

A dust collector and spray type technology, applied in the field of machinery, can solve the problems of damage to the motor, high equipment prices, and the inability to recycle metal powder, and achieve the effects of increasing the contact area, wide application range and high adsorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

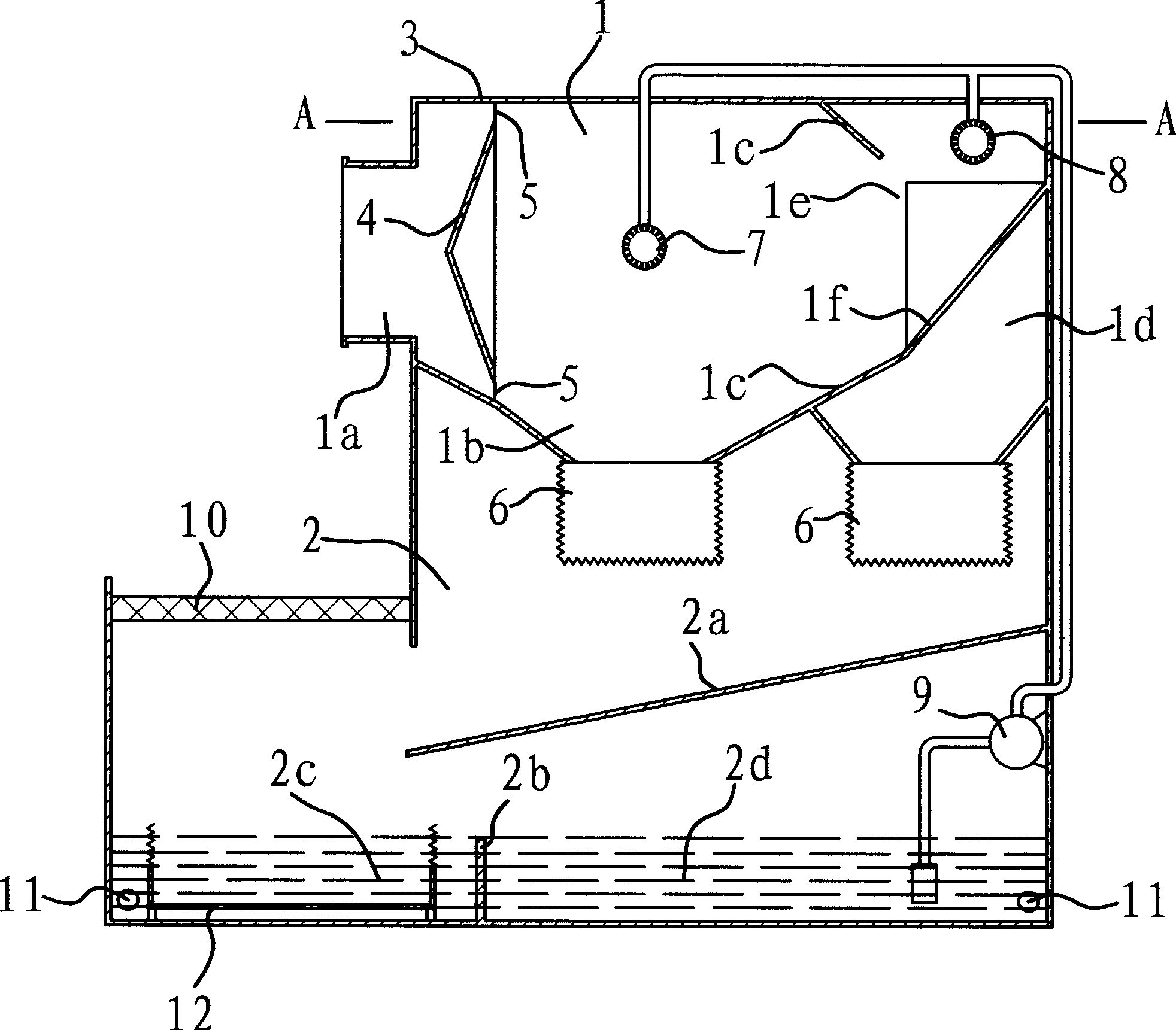

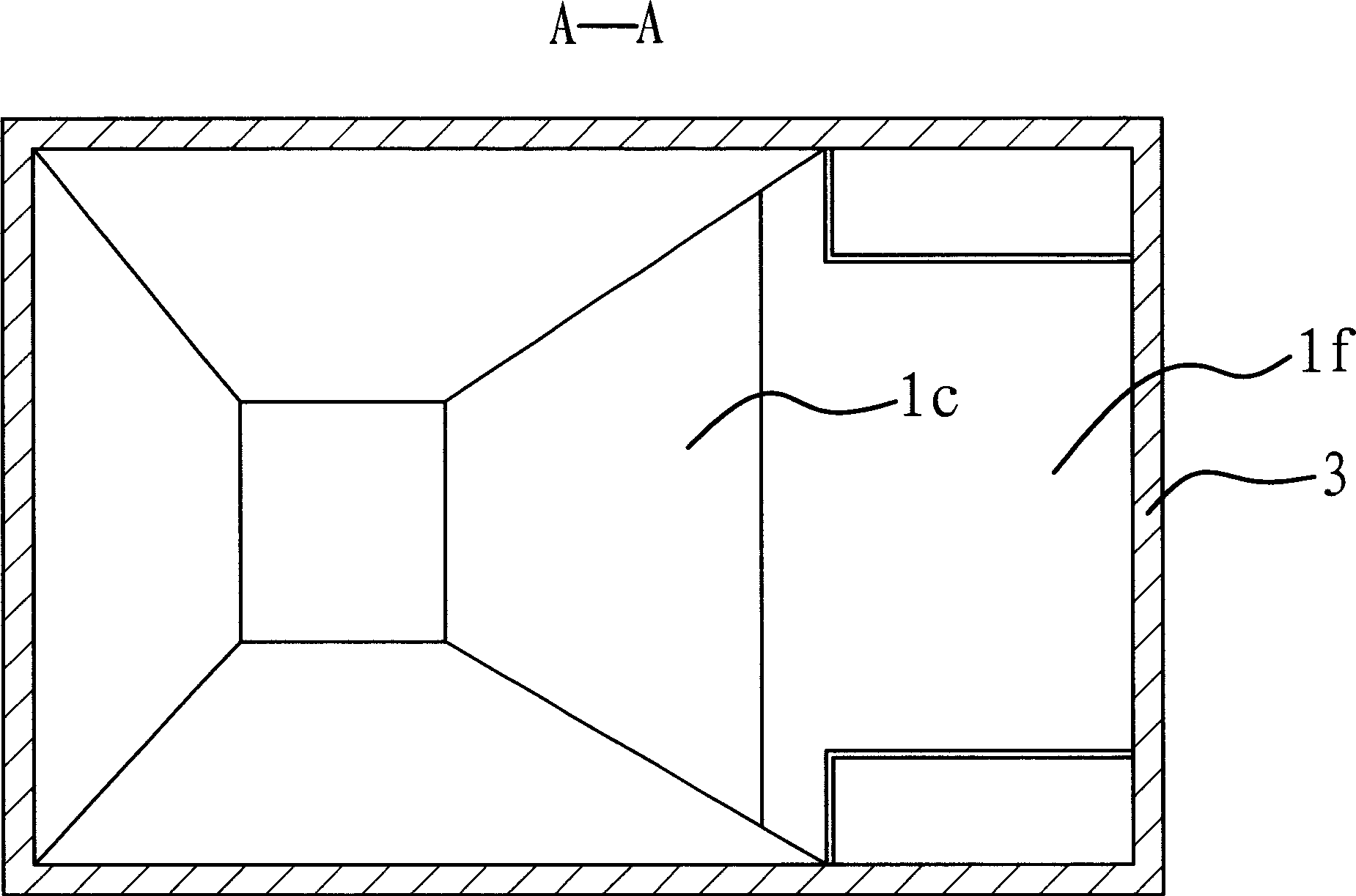

[0020] Such as figure 1 As shown, the spray dust collector transports the dust airflow into the dust collector through the air pipe, and then performs dust removal. It includes a hollow casing 3, and the partition divides the casing 3 into two chambers: a spray chamber 1 and an airflow chamber 2. The spray chamber 1 is provided with a spray head 7, through which the spray head 7 sprays water mist to spray the air flow in the chamber, so that the water mist absorbs the dust in the air flow, and when the water flow passes through the filter box 6, the dust is retained At the bottom of filter box 6.

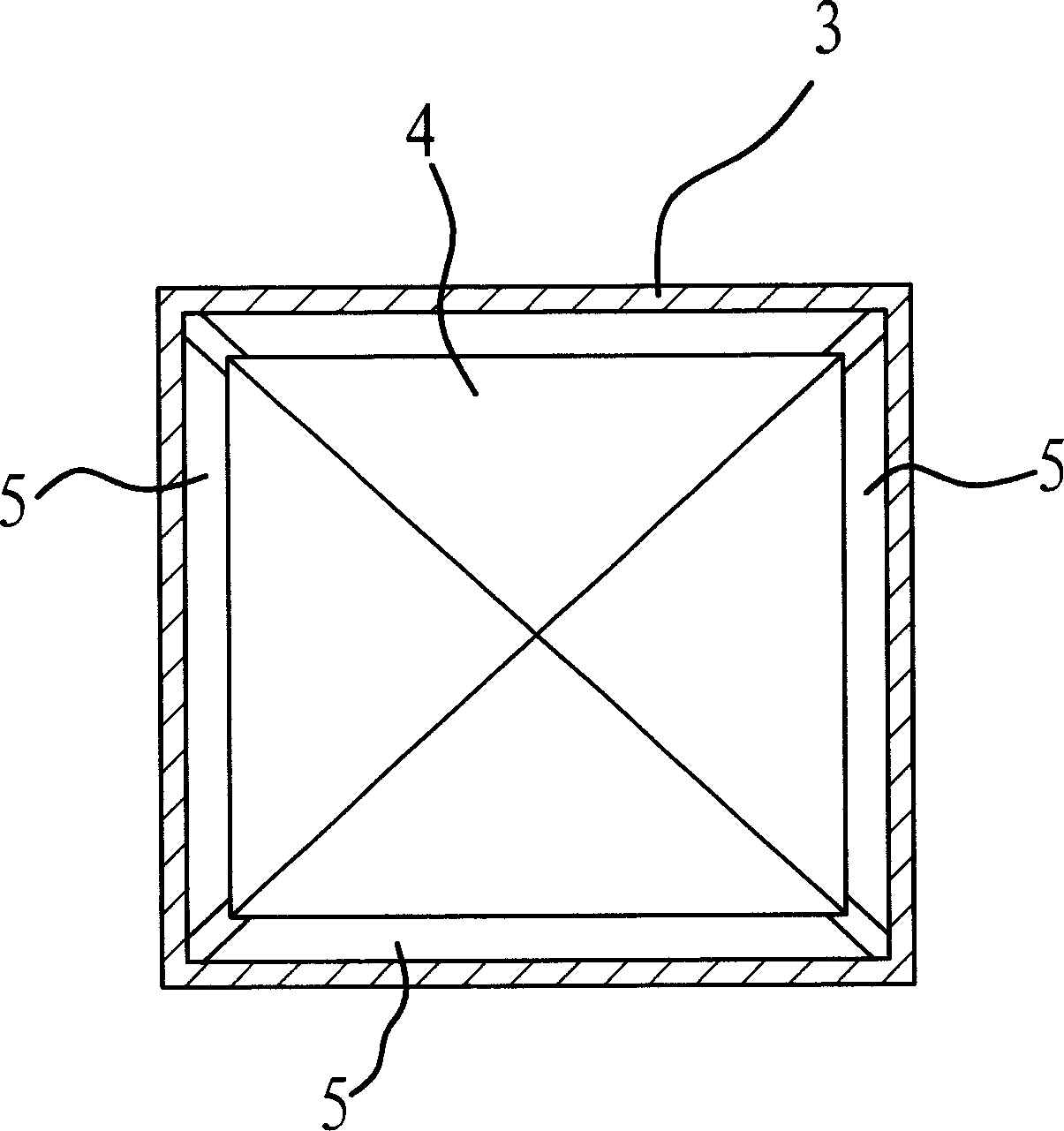

[0021] Such as figure 1 and image 3 As shown, there is an air inlet 1a on the casing 3 . A conical air-dispersing partition 4 is fixedly attached to the casing 3, which is close to the air inlet 1a. In this embodiment, the air-dissipating partition 4 is pyramid-shaped. An air inlet gap 5 is left between the surroundings of the diffused air partition 4 and the housing 3 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com