Wire material supplying mechanism of tubular braided fabric braiding machine

A technology for manufacturing machines and braids, which is applied in the field of manufacturing devices for tubular braids. It can solve problems such as uneven wrapping of winding spirals, disordered force changes of special-shaped cam plates, and broken wires of raw materials, so as to improve transmission quality, Avoid the problem of disorder and disconnection, and overcome the effect of centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

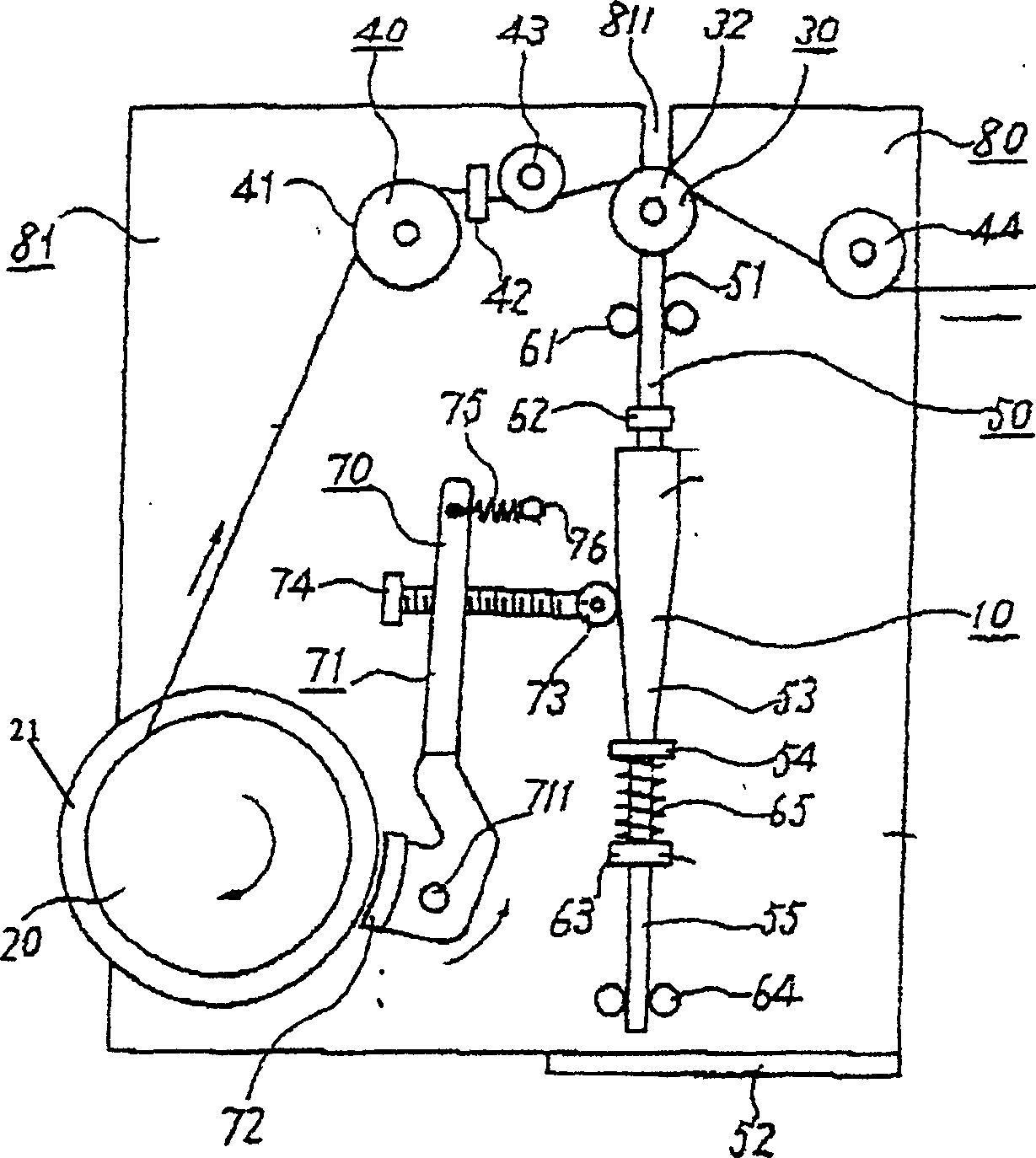

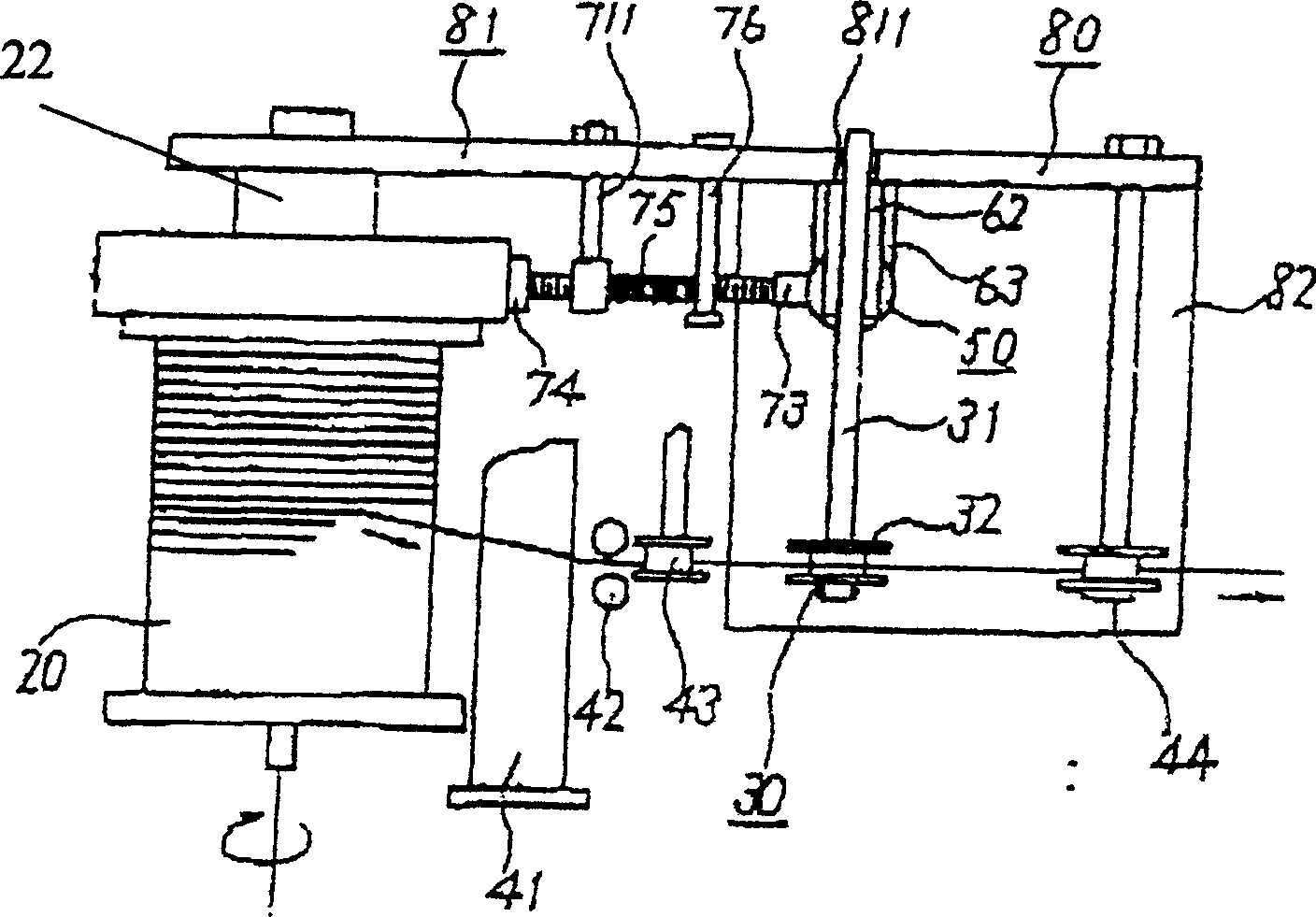

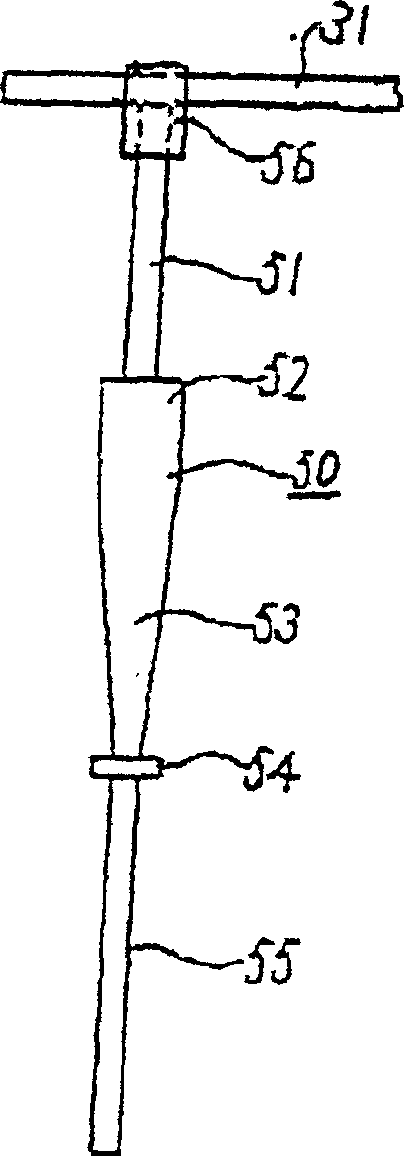

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the wire supply mechanism of a tubular braid manufacturing machine of the present invention is composed of a frame 80 and a wire tension adjustment mechanism. The frame 80 is provided with a feeding drum support shaft 22, wherein the The frame 80 is composed of a support plate 81, the wire tension adjustment mechanism is composed of a tension detection mechanism 10 and a braking device 70, and the tension detection mechanism 10 is composed of a fixed roller group 40 and a floating roller mechanism 30, the fixed roller group 40 is composed of at least one input roller 41 and one output roller 44, the input roller 41 and the output roller 44 are respectively arranged on the support plate 81 through the installation shaft, the described The floating roller mechanism 30 is composed of a floating roller 32, a floating roller support shaft 31 and a transmission rod 50. The floating roller 32 is arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com