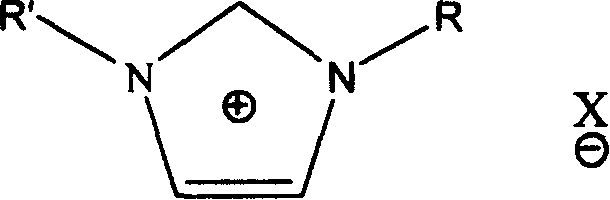

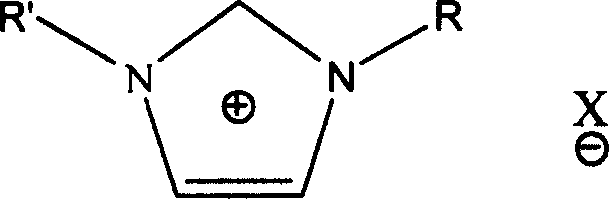

Method for preparing ion liquid in halogenated alkyl imidazole type

A halogenated alkylimidazole-type ionic liquid technology, which is applied in the new preparation field of ionic liquids, can solve the problems of low utilization rate of raw material halogenated hydrocarbons, complex process, etc., and achieve the effect of eliminating environmental problems, simple operation, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

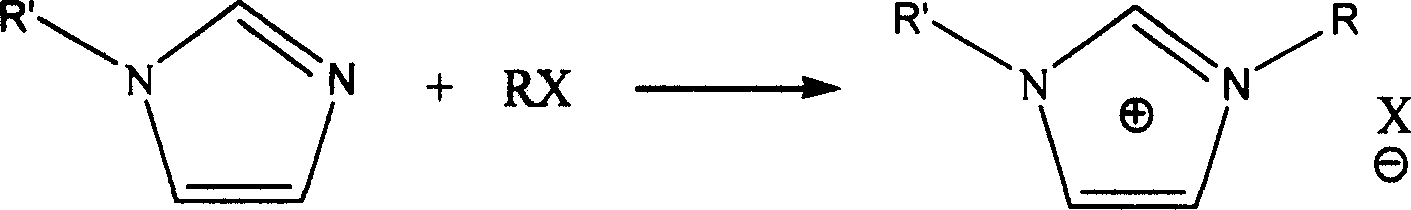

Method used

Image

Examples

Embodiment 1

[0021] In a 200ml sealable reactor, 8.212g (0.100mol) of N-methylimidazole and 9.720g (0.105mol) of 1-chlorobutane were sequentially added, and the reaction was stirred at 40°C for 24 hours. After the reaction, the supercritical CO 2 , at a pressure of 7.0 MPa and a temperature of 40 °C, CO 2 Flow rate 1.0L / min, continuous extraction for 4 hours, the product N,N-butylmethylimidazolium chloride salt 14.796g and unreacted reactant 3.136g (containing chlorobutane 1.875g and N-methylimidazole 1.261g) were isolated; The yield based on chlorobutane was 80.7%.

Embodiment 2

[0023] In a 200ml sealable reactor, 12.318g (0.150mol) of N-methylimidazole and 15.135g (0.163mol) of 1-chlorobutane were sequentially added, and the reaction was stirred at 80°C for 12 hours. After the reaction is over, supercritical CO 2 , at a pressure of 20.0 MPa and a temperature of 80 °C, CO 2 Flow rate 1.0L / min, continuous extraction for 4 hours, the product N,N-butylmethylimidazolium chloride salt 24.249g and unreacted reactant 3.204g (containing chlorobutane 2.285g and N-methylimidazole 0.919g) were isolated; The yield calculated by chlorobutane is 84.9%.

Embodiment 3

[0025] In a 200ml sealable reactor, 16.424g (0.200mol) of N-methylimidazole and 19.440g (0.210mol) of 1-chlorobutane were sequentially added, and the reaction was stirred at 150°C for 8 hours. After the reaction is over, supercritical CO 2 , at a pressure of 15.0 MPa and a temperature of 150 °C, CO 2 Flow rate 1.0L / min, continuous extraction for 3 hours, the product N,N-butylmethylimidazolium chloride salt 33.568g and unreacted reactant 2.296g (containing chlorobutane 1.652g and N-methylimidazole 0.644g) were separated; The yield based on chlorobutane is 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com