Pile tip displacement regulating device

A technology of displacement adjustment and pile tip, which is applied in the direction of construction and infrastructure engineering, etc., can solve the problems of low bearing capacity, huge consumption of manpower and material resources, troubles, etc., and achieve the effect of convenient adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

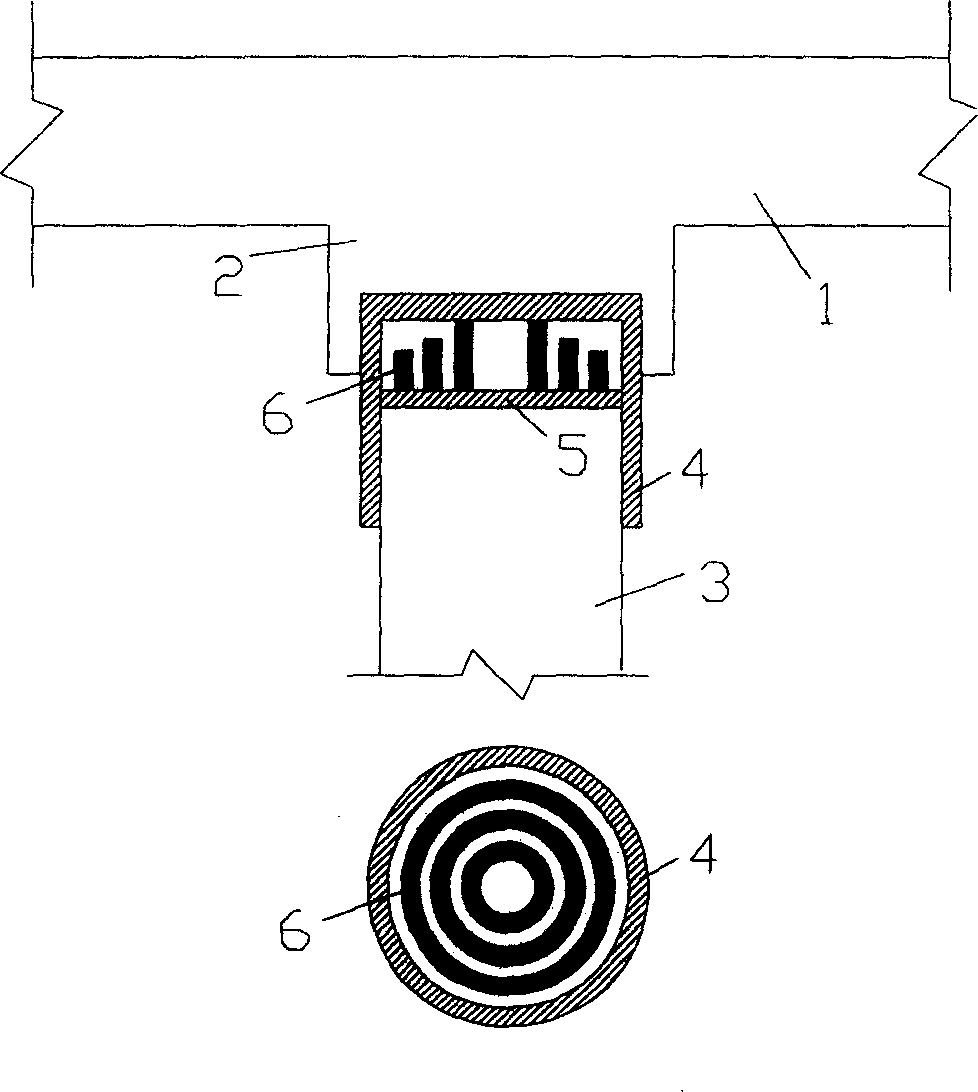

Embodiment 1

[0020] A pile end displacement adjustment device for adjusting pile end displacement, which is composed of a cylinder body 4, a top plate 5 and a telescopic element, the top plate 5 and the telescopic element are arranged in the cylinder body 4, and the telescopic element is located in In the formed cavity, the telescopic element can adopt a displacement adjustment steel plate standing between the inner end surface of the cylinder body 4 and the top plate 5. The displacement adjustment steel plate is cylindrical and can be composed of cylindrical steel plates 6 with different diameters. Shaped steel plates 6 are nested together in order of diameters from small to large, and the cylindrical steel plates are selected from common HPB235 steel. The height difference and spacing of the steel plates should be 1cm and 2cm respectively, and the number of turns should be about 6 turns. The height of the inner ring steel plate and the thickness of the steel plate can be adjusted accordin...

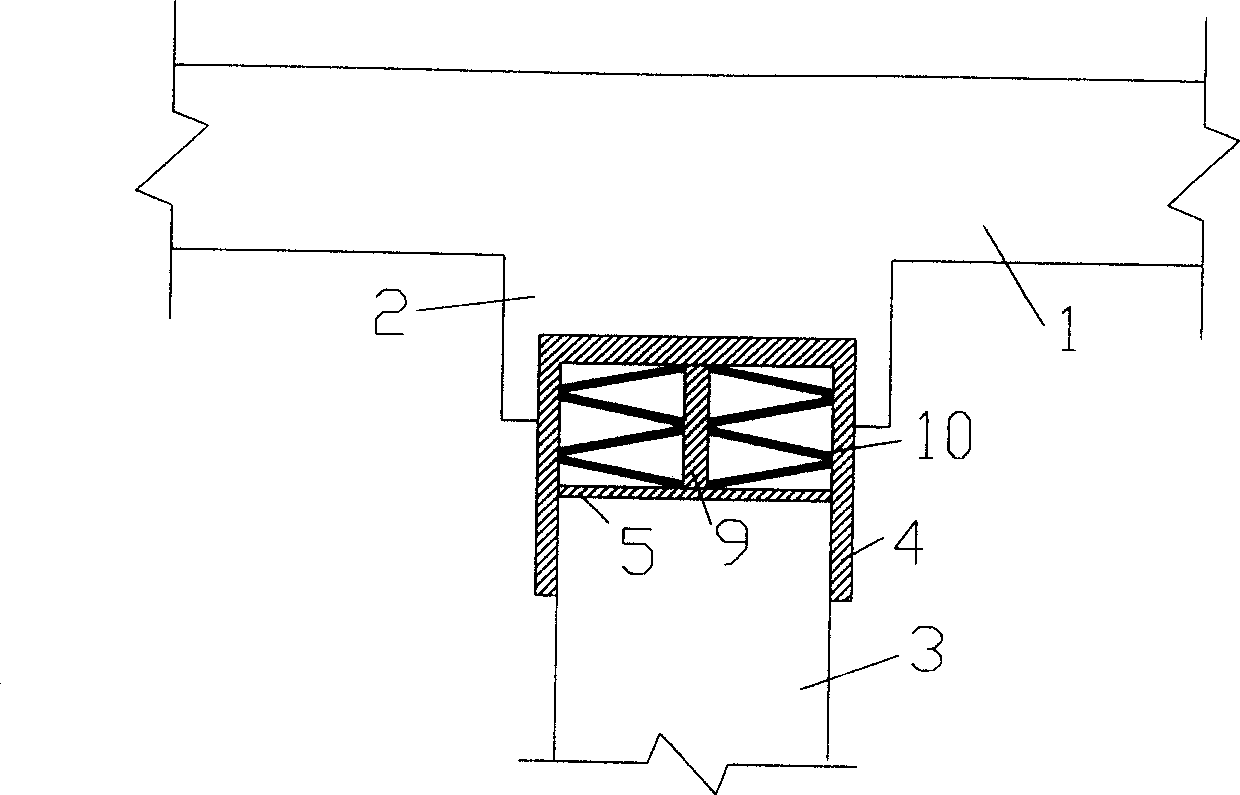

Embodiment 2

[0022] A pile end displacement adjustment device for adjusting pile end displacement, which is composed of a cylinder body 4, a top plate 5 and a telescopic element, the top plate 5 and the telescopic element are arranged in the cylinder body 4, and the telescopic element is located in In the formed cavity, the telescopic element adopts a disc spring 10, and a central steel column 9 is arranged at the center of the disc spring 10. The above-mentioned disc springs can be directly selected in the disc spring specification table according to the calculated pile support stiffness and displacement adjustment.

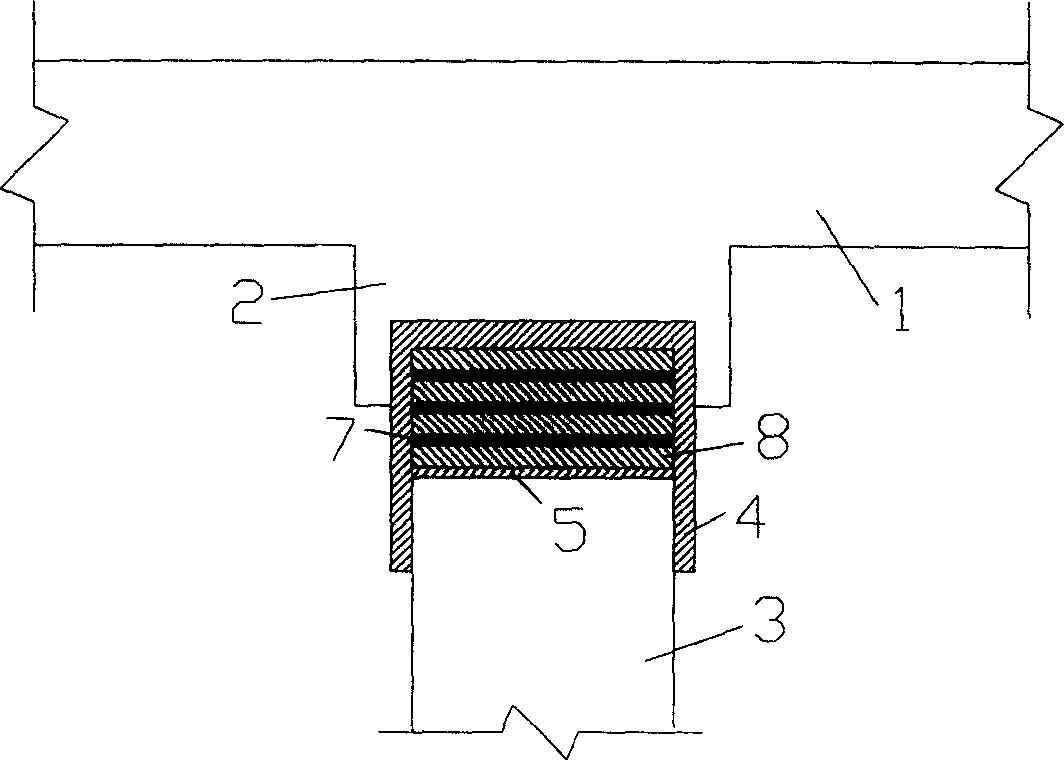

Embodiment 3

[0024] A pile end displacement adjustment device for adjusting pile end displacement, which is composed of a cylinder body 4, a top plate 5 and a telescopic element, the top plate 5 and the telescopic element are arranged in the cylinder body 4, and the telescopic element is located in In the formed cavity, wherein the telescopic element adopts a rubber pad 8, and more than 2 (such as: 3, 5 or 7 rubber pads) superimposed rubber pads 8 can be used, between adjacent rubber pads There is a steel plate 7 between them, and the above-mentioned rubber pad can use JGD-D type shock-absorbing rubber pad (if rubber pads of other specifications are used, they must meet the corresponding regulations in the "Code for Seismic Design of Buildings" (GB50011-2001)). Its stiffness and thickness can be adjusted as required. Specifically: according to the calculated pile support stiffness, select the corresponding type of rubber pad, and then calculate the height of the rubber pad according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com