Novel insulated main lead

A technology of insulated busbars and busbars, applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve the problems of high local potential and easy aging of the end insulation layer, and achieve the effects of reducing aging, improving power supply reliability, and extending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

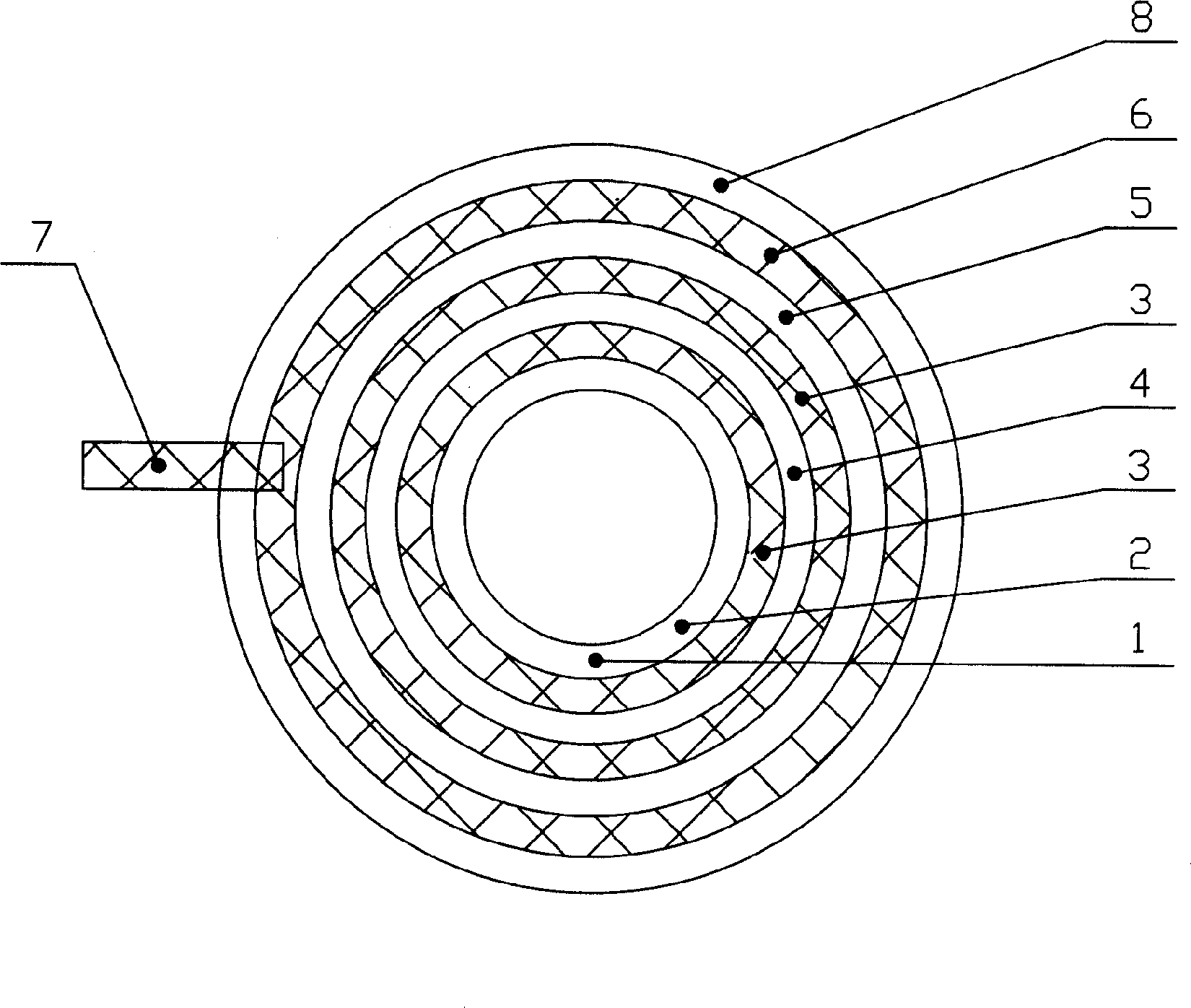

[0011] exist figure 1 Among them, install an insulating layer (3) on the conductor of the copper tube (1), install a metal capacitive screen (4) on the insulating layer (3), install n insulating layers (3) according to the voltage level, and install n insulating layers (3) according to the voltage level. Install n metal capacitive screens (4), without screen, the potential of the ground screen is zero (the ground screen is composed of a semiconductor layer (5) and a conductive metal layer (6), and the ground screen leads to a grounding metal strip (7) for grounding , an insulating sheath layer (8) needs to be installed outside the ground screen for protection of the ground screen.

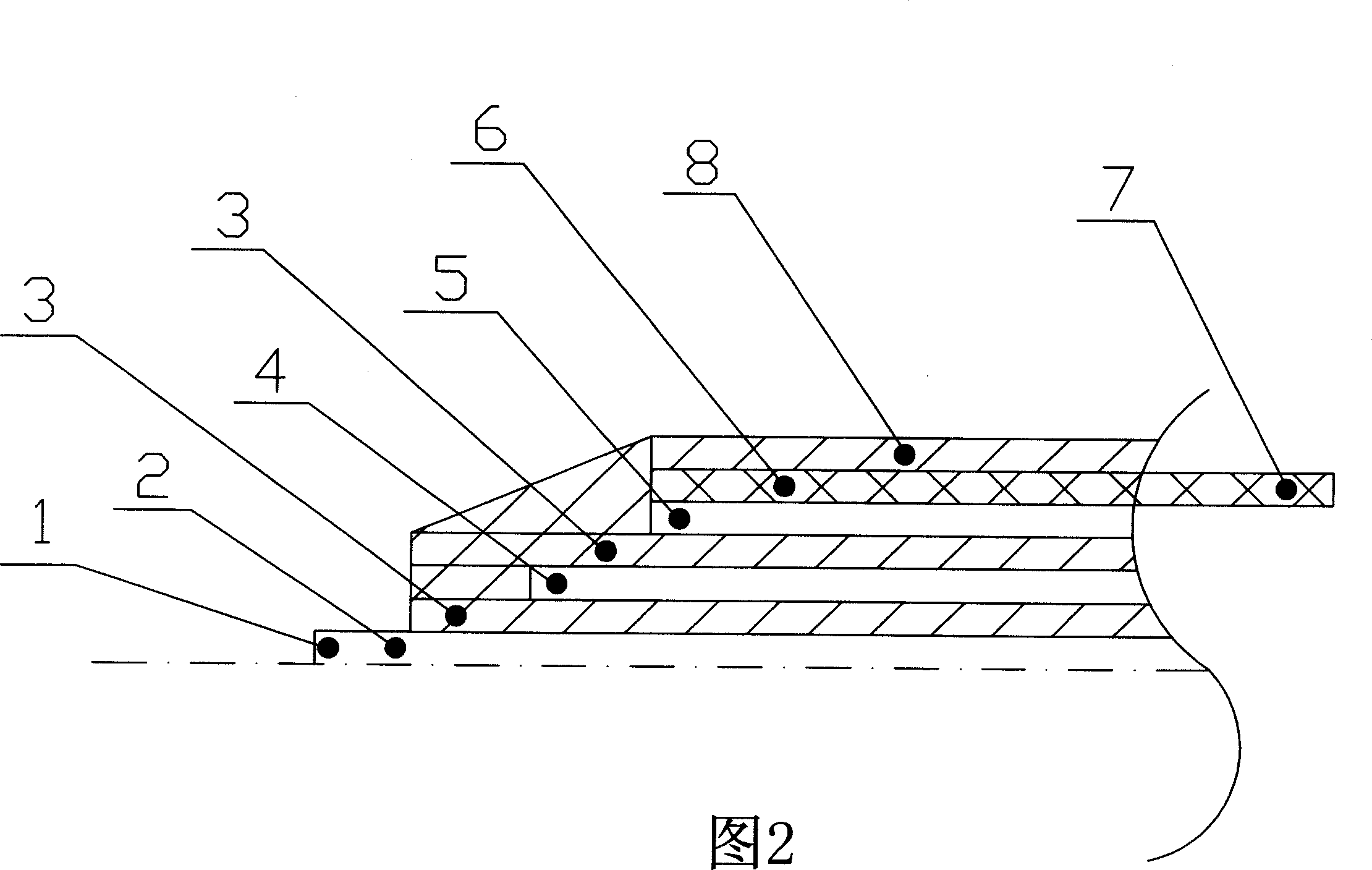

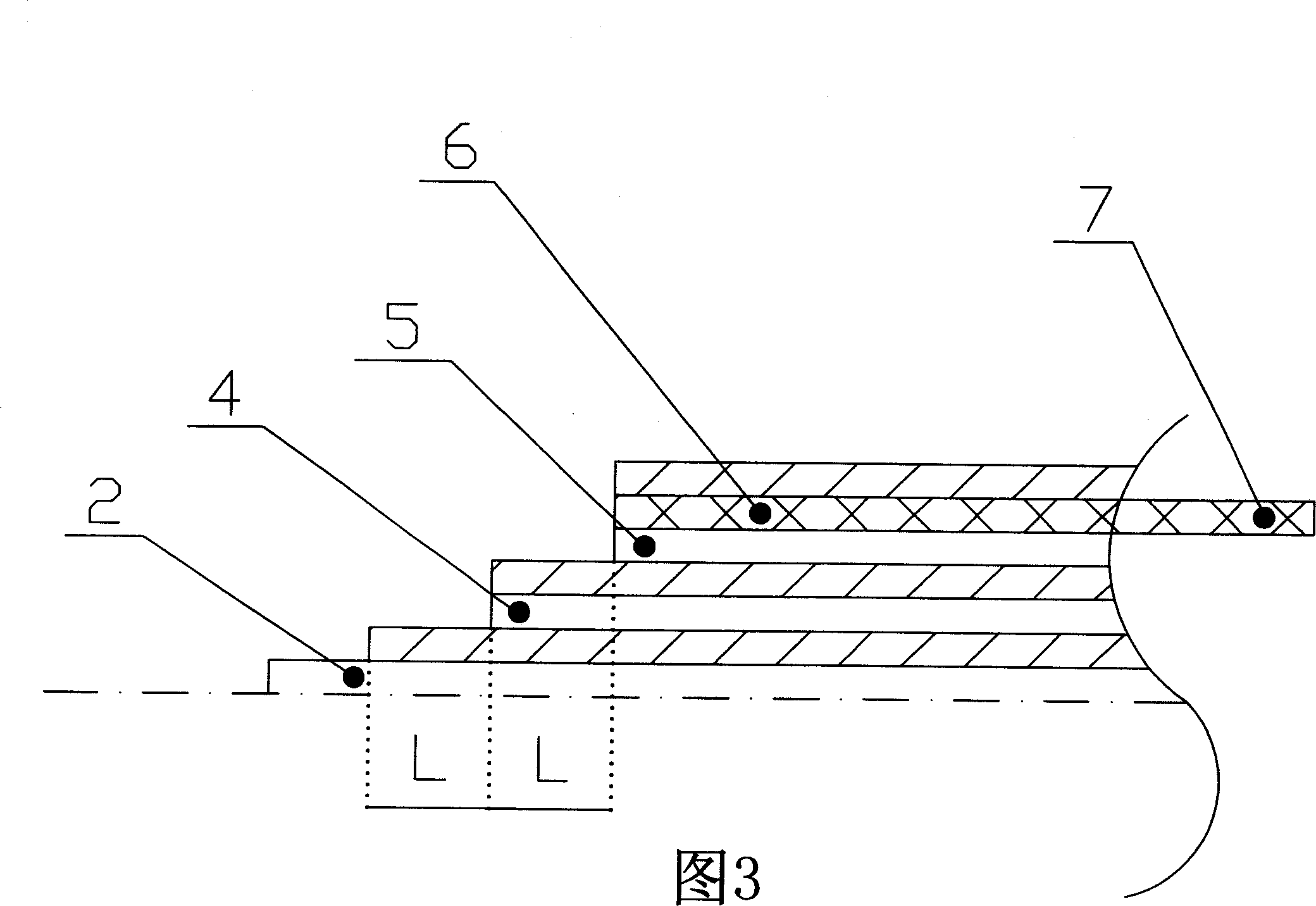

[0012] In the embodiment shown in Fig. 2, an insulating layer (3) is installed on the copper pipe (1) conductor, a metal capacitive screen (4) is installed on the insulating layer (3), and n insulating layers are installed according to the voltage level (3), add n metal capacitive screens (4) acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com