Inverter feed multi three-phase squirrel-cage asynchronous motor

A technology for asynchronous motors and inverters, applied in the direction of asynchronous induction motors, DC motor speed/torque control, electrical components, etc., can solve problems such as the complexity of generators, and achieve improved torque characteristics, harmonic weakening, and reliability sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

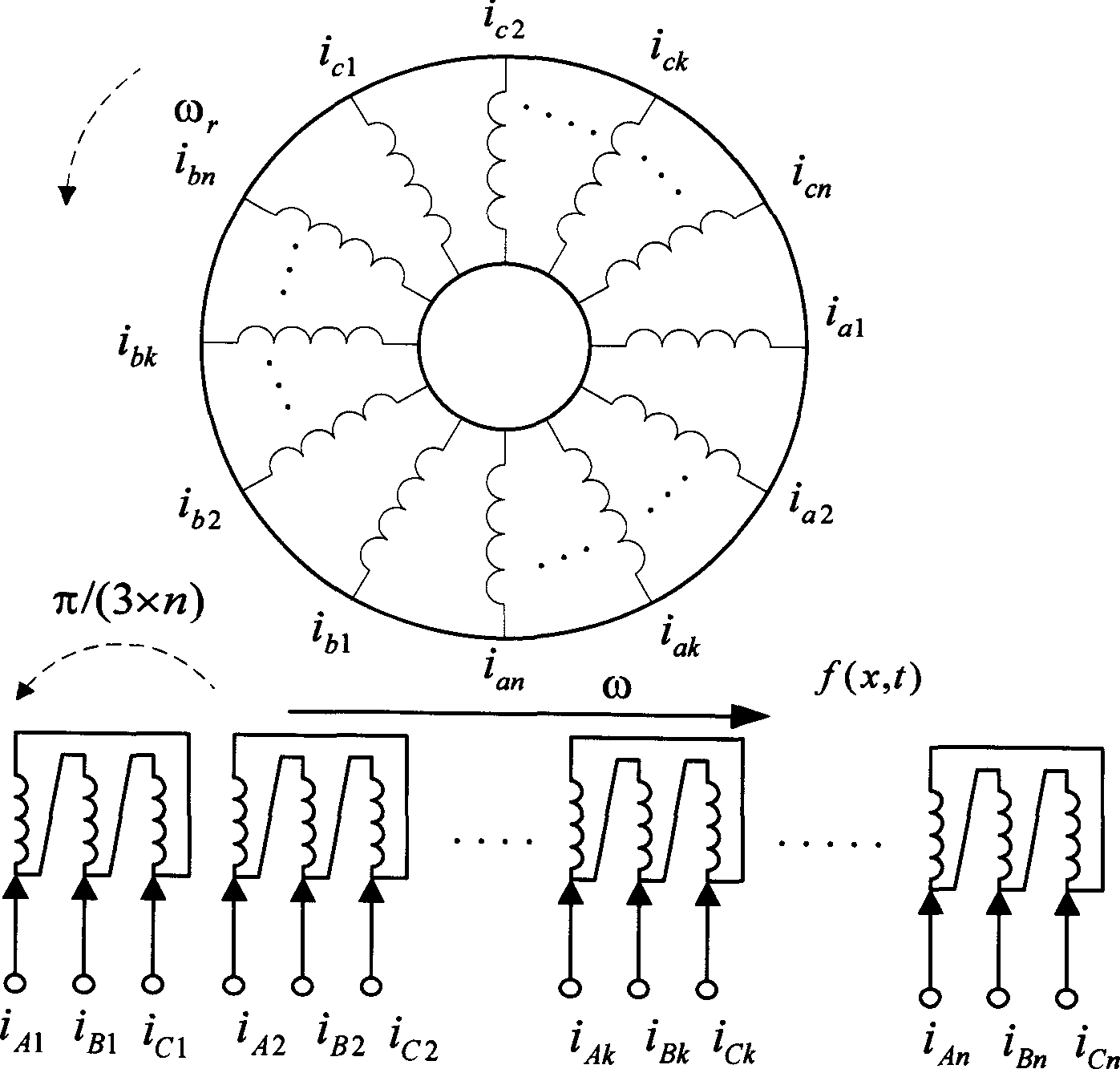

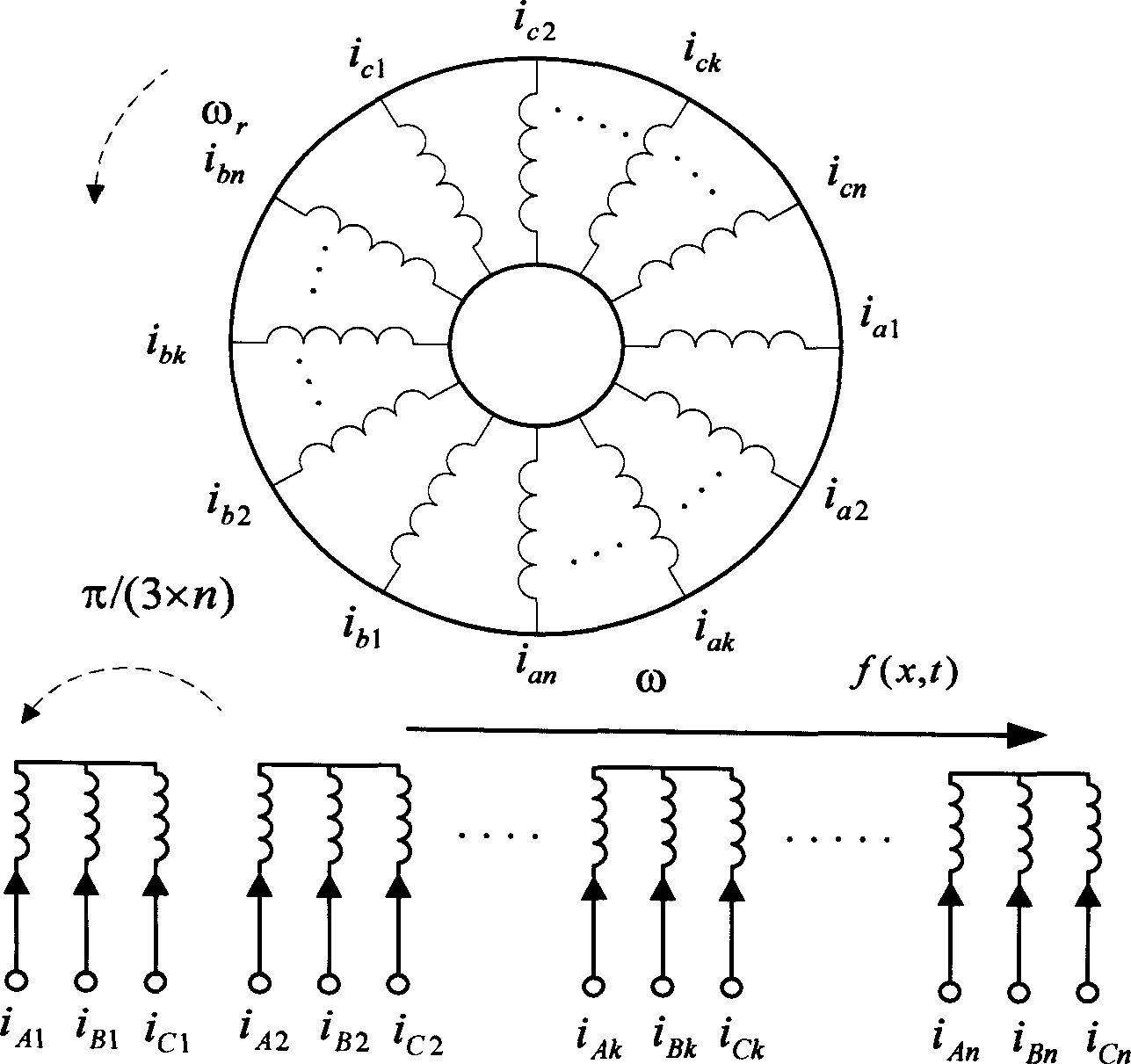

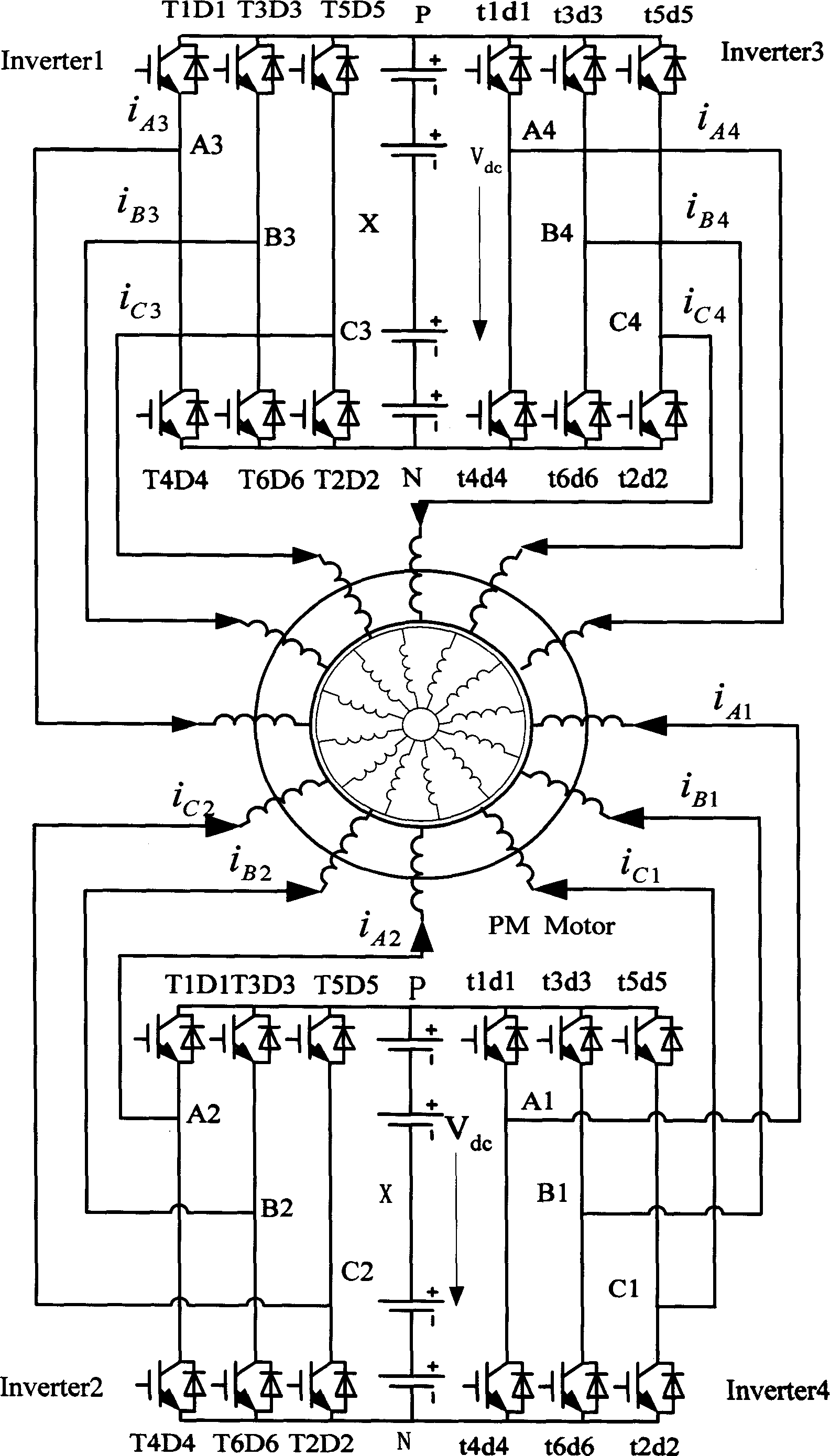

[0053] In the accompanying drawings, Figure 5-Figure 6 It is an embodiment of multi-three-phase squirrel-cage asynchronous motor. Figure 5-Figure 6 In a multi-three-phase system, the slot potential star diagram of the 4×3-phase stator winding is used. It can be seen from the slot potential star diagram that the 4×3 phase system includes 4 sets of three-phase symmetrical windings. In this embodiment, the number of stator slots of the squirrel-cage asynchronous motor is Z=144, and the number of magnetic poles 2p=8. The number of slots per pole phase is q=1.5, and the pole distance τ=18. Since the power of multi-phase motors is generally large, it is common to use double-layer windings. This embodiment can also use single-layer windings. The winding pitch can be full-pitch winding y=τ, or short-pitch winding y = 8 9 τ = 16 (groove). The space electrical angle between adjacent inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com