Inverter feed multi three-phase AC synchronous motor

A synchronous motor, three-phase synchronous technology, applied to synchronous motors for single-phase current, DC motor speed/torque control, electrical components, etc., can solve the problems of complex generators, and achieve simple wiring and reliable windings. High performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

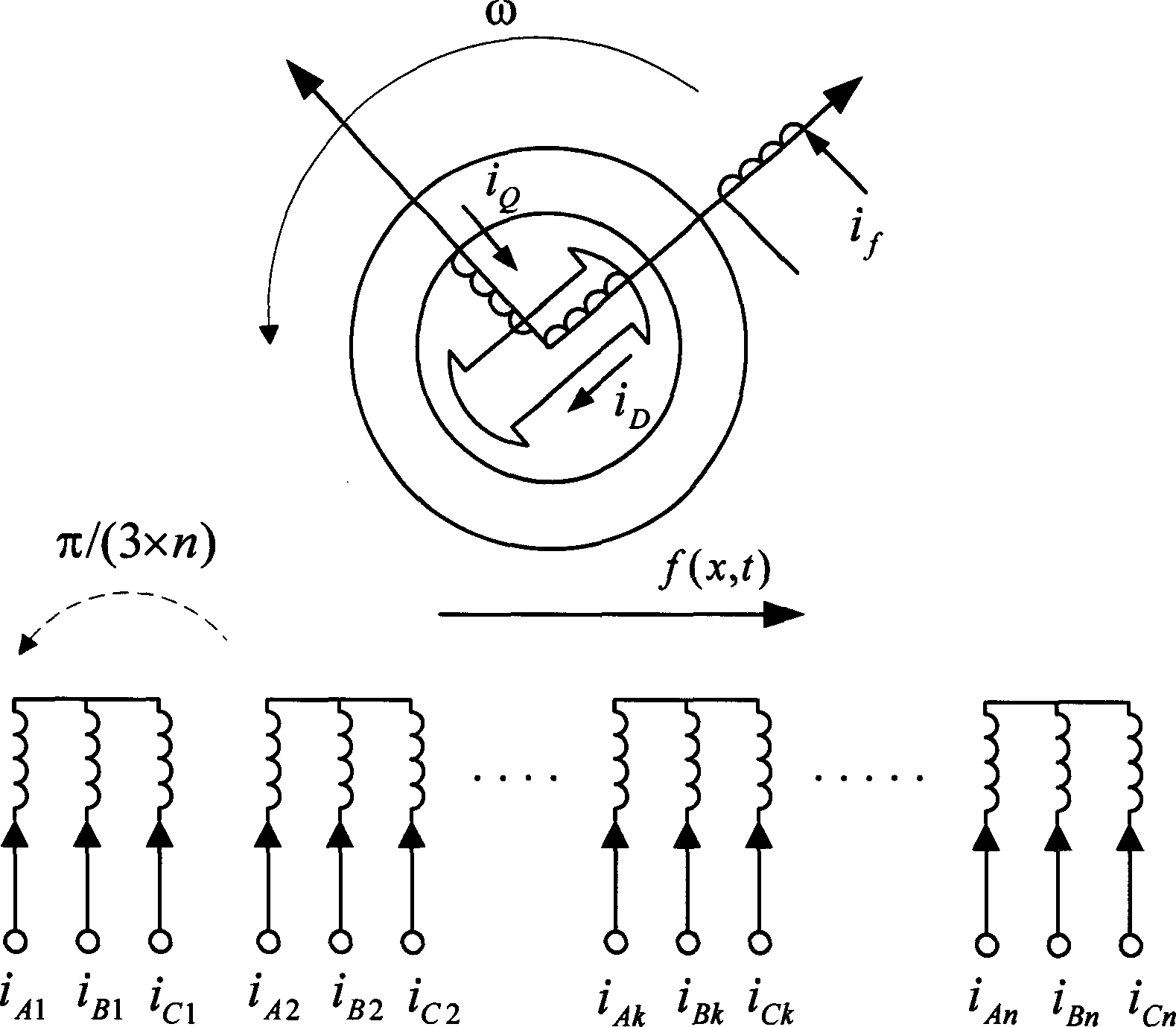

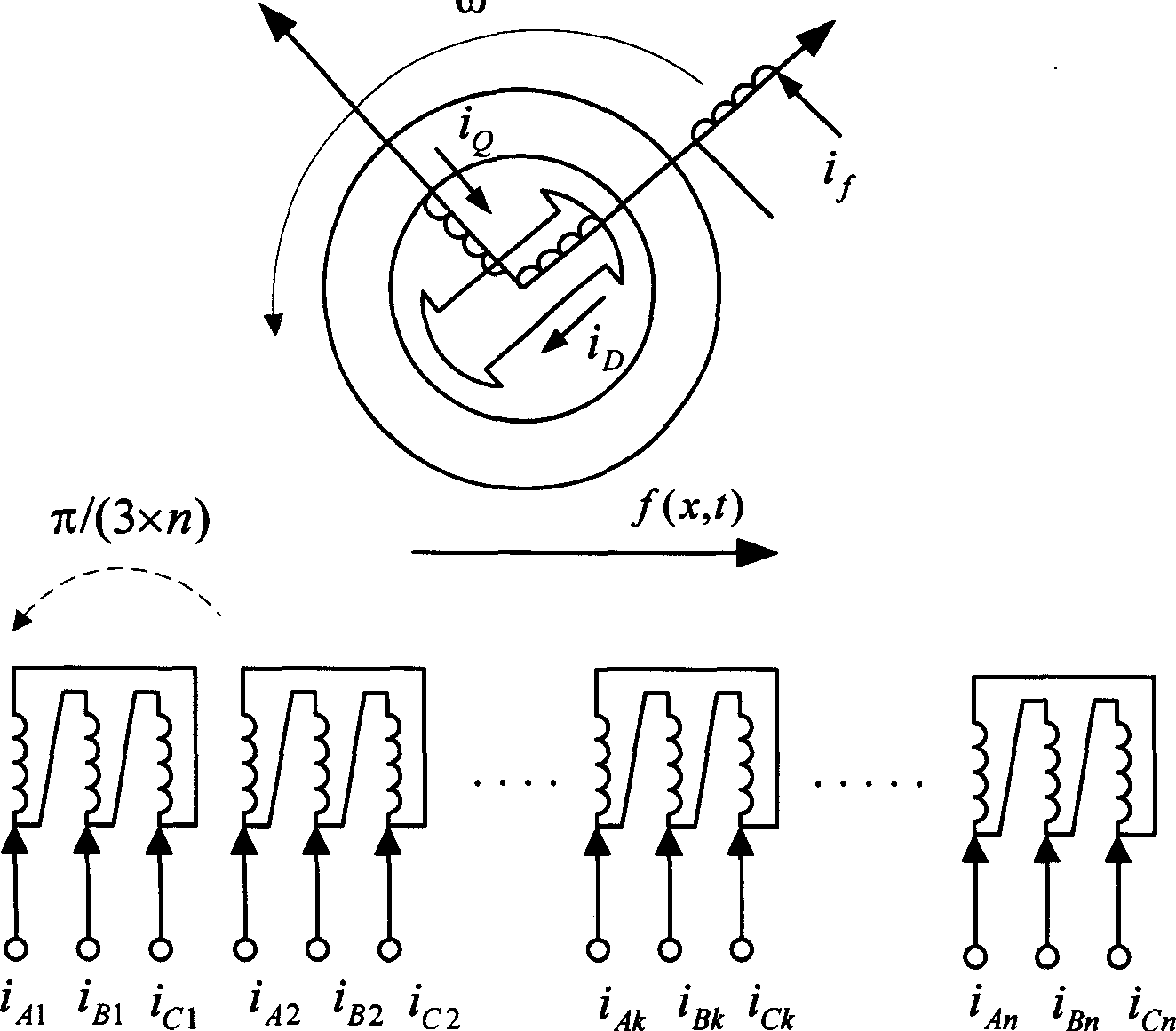

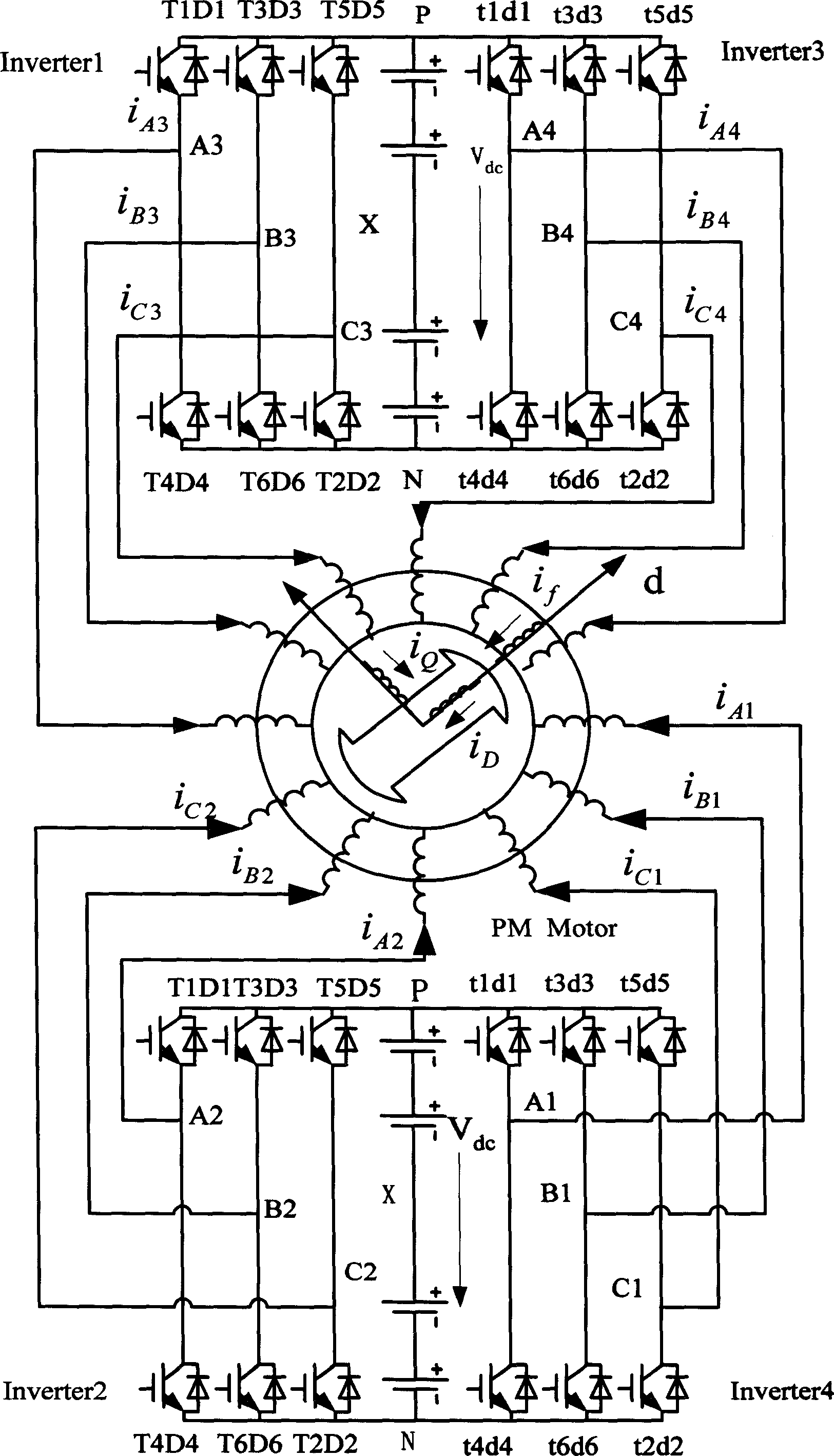

[0050] Instructions attached Figure 5 It is an embodiment of multiple three-phase synchronous motors. Figure 5 In a multi-three-phase system, the slot potential star diagram of the 4×3-phase stator winding is used. It can be seen from the slot potential star diagram that the 4×3 phase system includes 4 sets of three-phase symmetrical windings. In this embodiment, the number of stator slots of the synchronous motor is Z=72, the number of magnetic poles is 2p=6, and each pole is The number of phase slots is q=1, and the pole pitch τ=12. Since the power of multi-phase motors is generally large, it is more common to use double-layer windings. This embodiment can also use single-layer windings. The winding pitch can be full-pitch winding y=τ, or short-pitch winding y = 5 6 τ = 10 (groove). The space electrical angle between adjacent independent three-phase windings is 180° / (4×3)=15°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com