Removable dust collector

A technology for vacuum cleaners and dust collectors, which is applied in the direction of vacuum cleaners, suction filters, chemical instruments and methods, etc., and can solve problems such as inconvenient use, damage to related components, difficult to assemble or disassemble filter locking parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

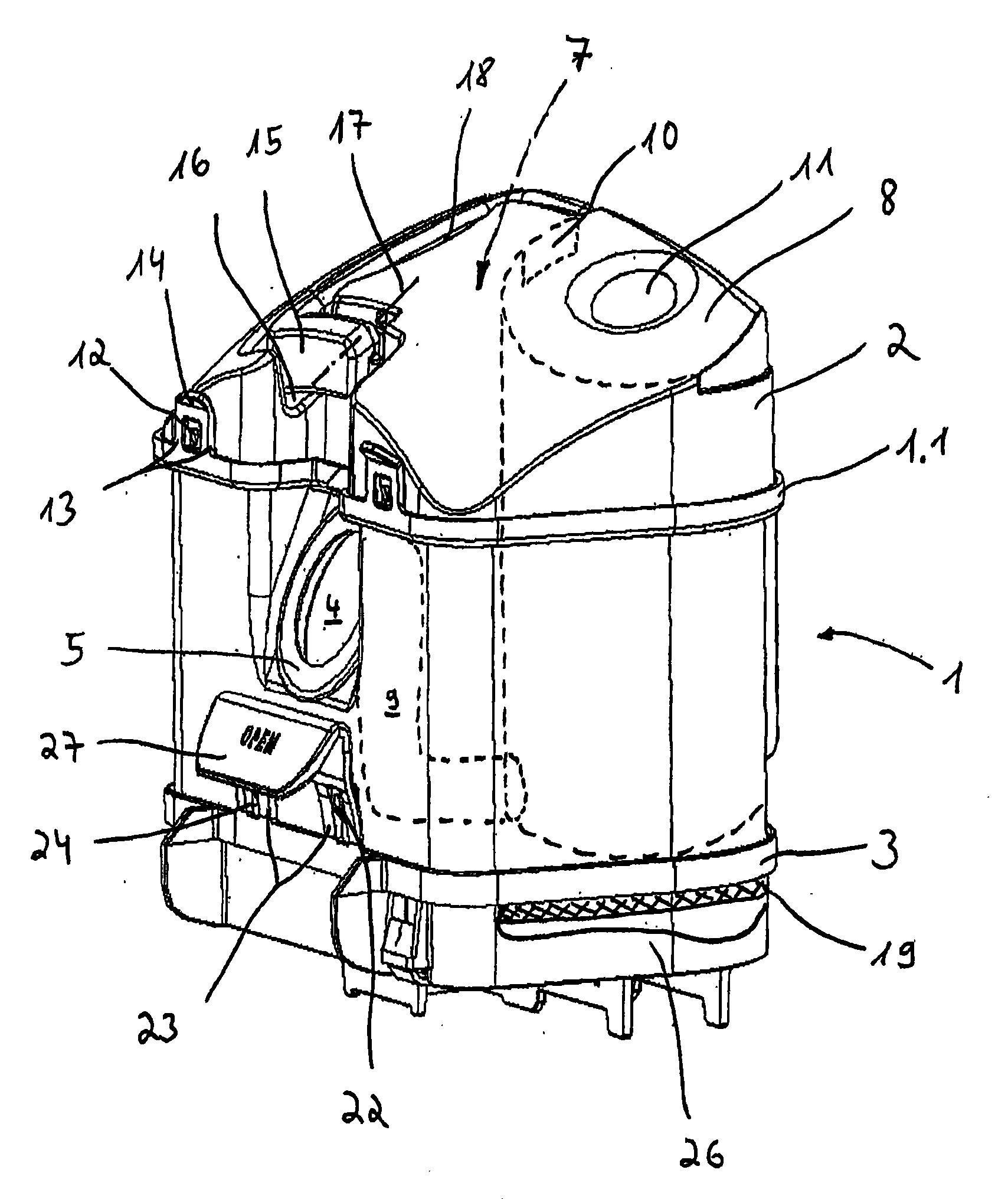

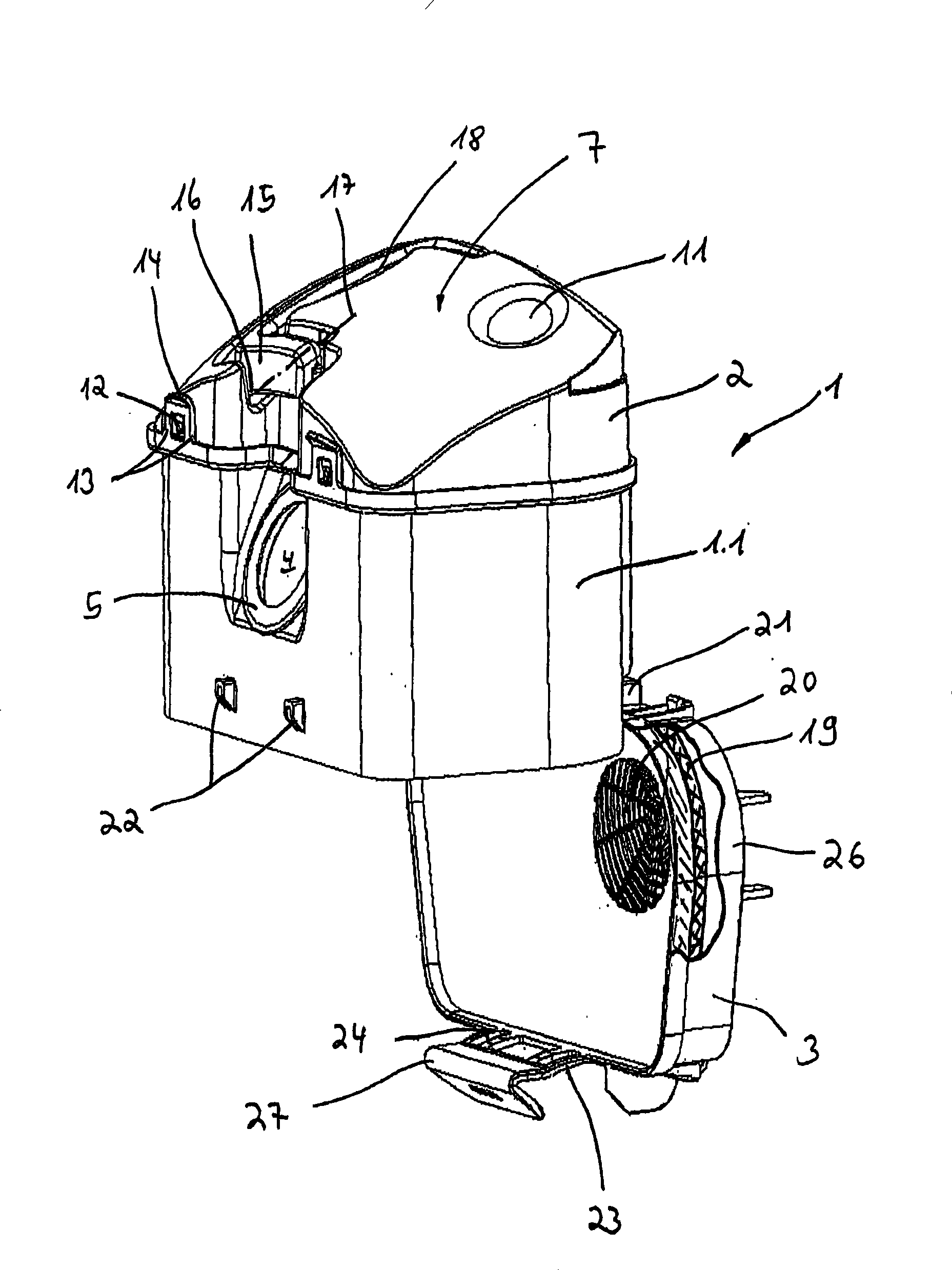

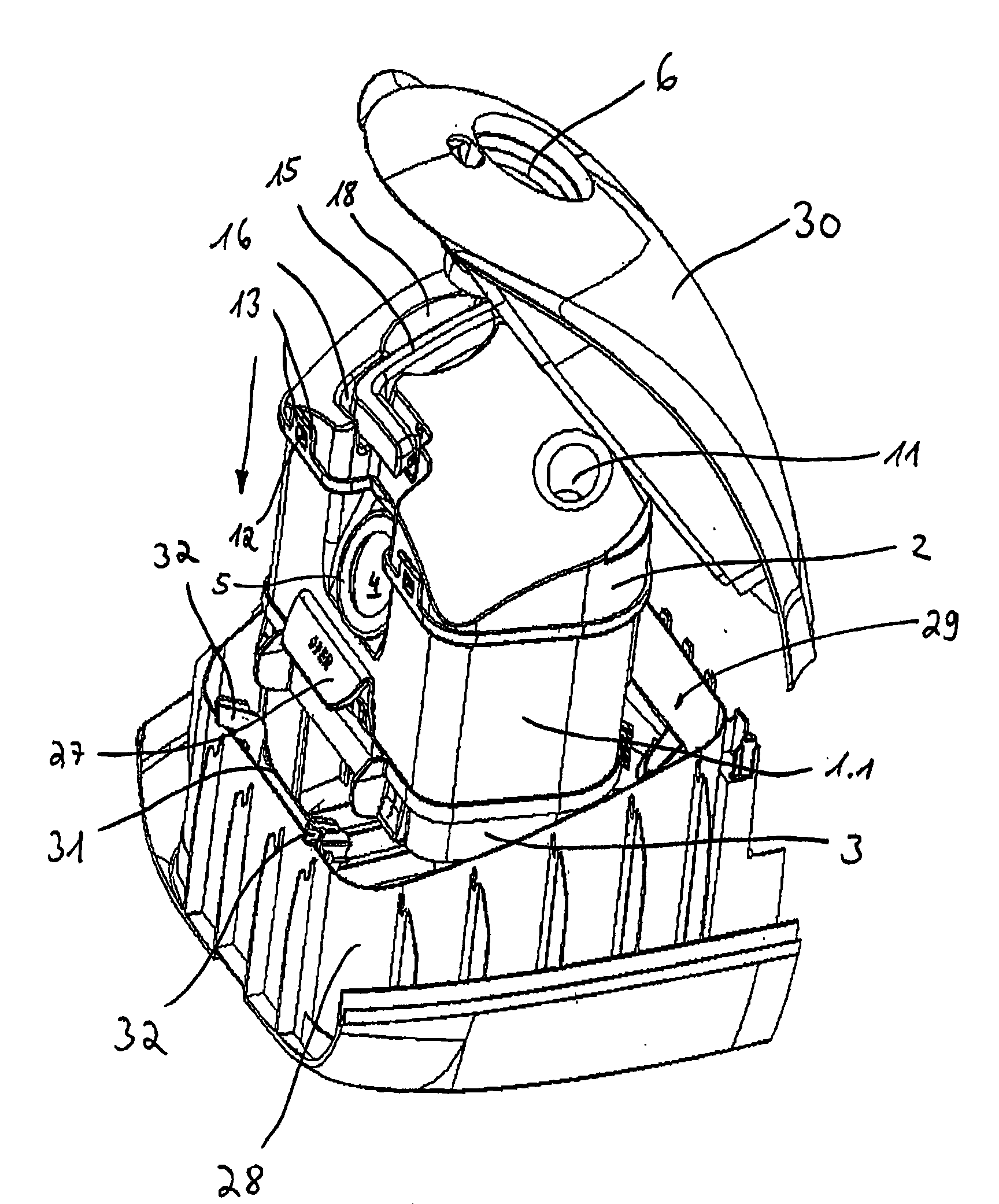

[0033] figure 1 A dust collector 1 is shown, which has a housing part 1.1, a container cover 2 and a bottom 3.

[0034] The housing part has an inlet opening 4 through which dust-laden air enters the interior of the dust collector 1 . A seal 5 is provided at the edge of the access opening 4 . On a working position of the dust collector 1, the dust collection chamber 7 of a dust collector is closed by a cover 30, and an inlet branch pipe 6 of the dust collector ( Figure 5 ) rests tightly against the seal 5 . Inside the housing part 1.1 there is a dust collection chamber 7 and a dust separator 8 . The dust separator 8 is designed as a centrifugal separator, but it can also be formed by a simple filter bag or a filter sieve. The dust separator 8 is connected to the inlet opening 4 via an inlet channel 9 . Dust is separated from the air in the dust separator 8 and enters the dust chamber 7 through an upper dust hole 10 . Dust collects on the bottom of the dust collection ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com