Light emitting element driving circuit, communication device and light emitting element driving method

A technology for driving circuits and light-emitting elements, which is applied in the layout of electric lamp circuits, circuits, electrical components, etc., can solve the problems of rapid deterioration, short life, and increased power consumption of VCSELs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, with reference to the accompanying drawings, the present invention will be described through the embodiments of the present invention, but the embodiments described below are not intended to limit the content of the present invention described in the claims, and the structures described below are not all of the present invention. Invention is a necessary element for solving technical problems.

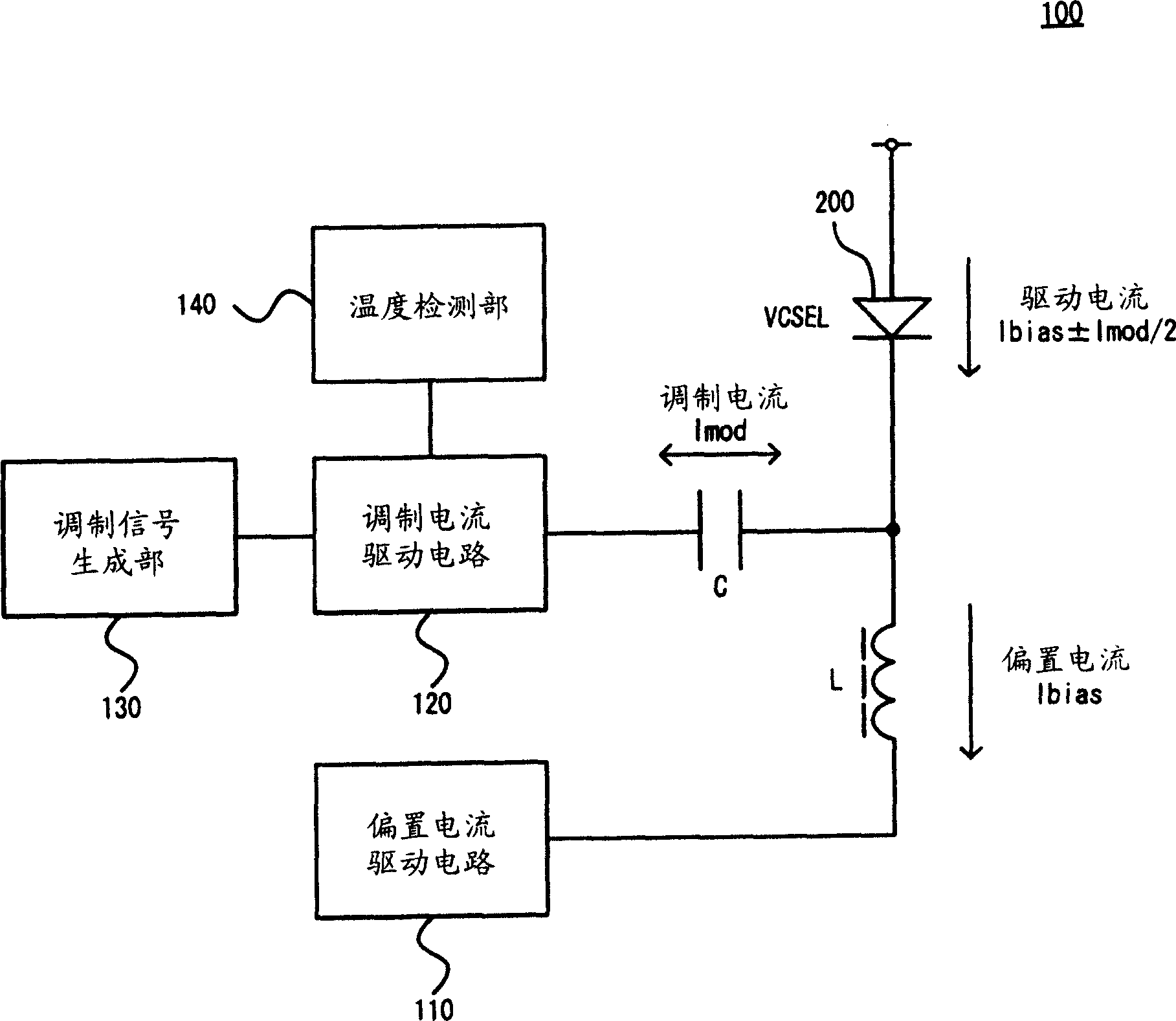

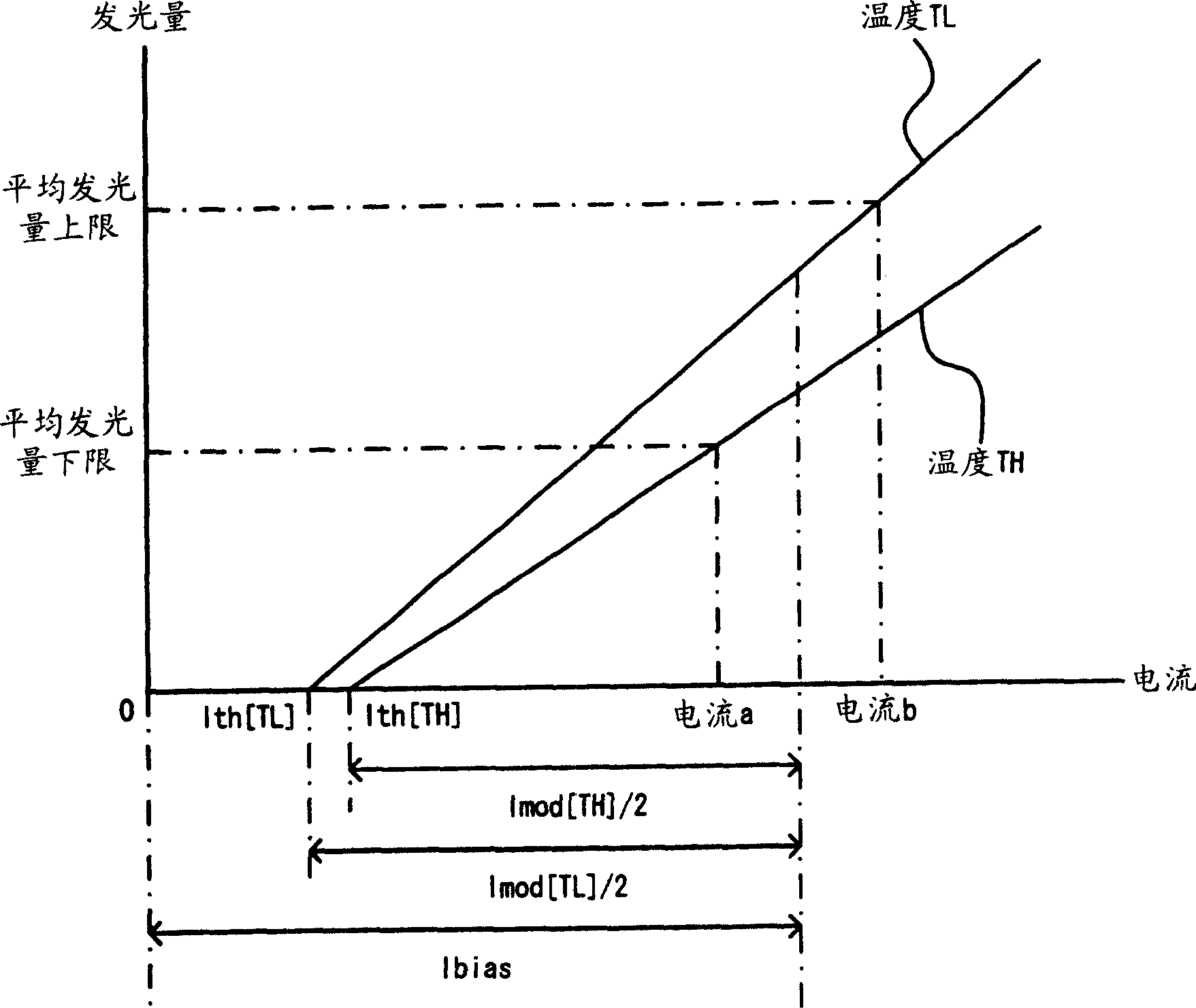

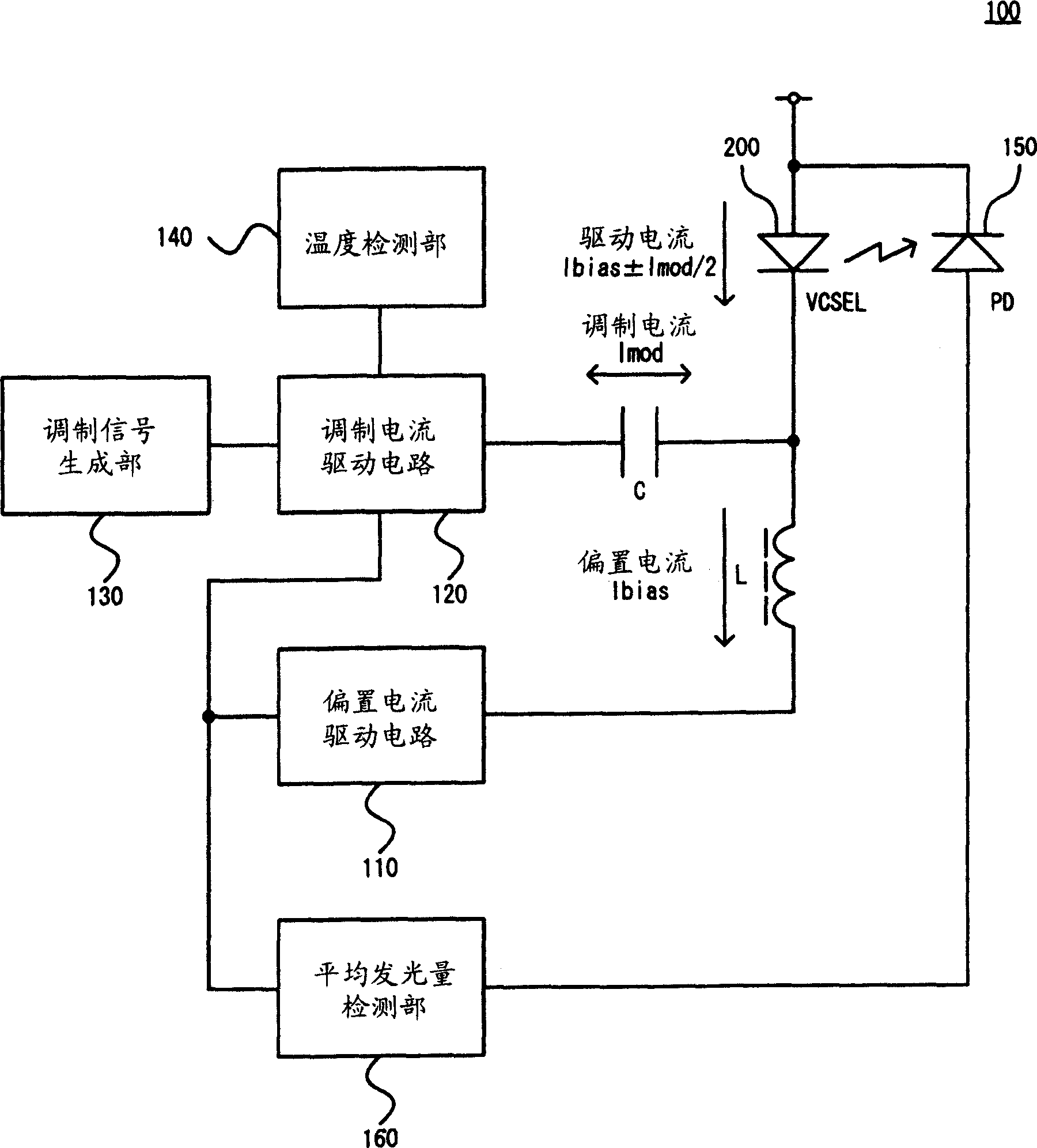

[0023] figure 1 is a schematic diagram of the first embodiment of the light emitting element driving circuit 100 of the present invention. The light emitting element drive circuit 100 includes a bias current drive circuit 110 , a modulation current drive circuit 120 , a modulation signal generation unit 130 , a temperature detection unit 140 , a capacitor C, and a coil L. The surface light-emitting element 200 driven by the light-emitting element driving circuit 100 of this embodiment is preferably a light-emitting element whose threshold current and slope efficiency var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com