Eccentric interference retention system for a filter cartridge

A filter cartridge and filter device technology, applied in filtration and separation, membrane filters, cartridge filters, etc., can solve problems such as uneven load, jeopardize the integrity of thread engagement efficiency, etc., and achieve the effect of eliminating electrostatic charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

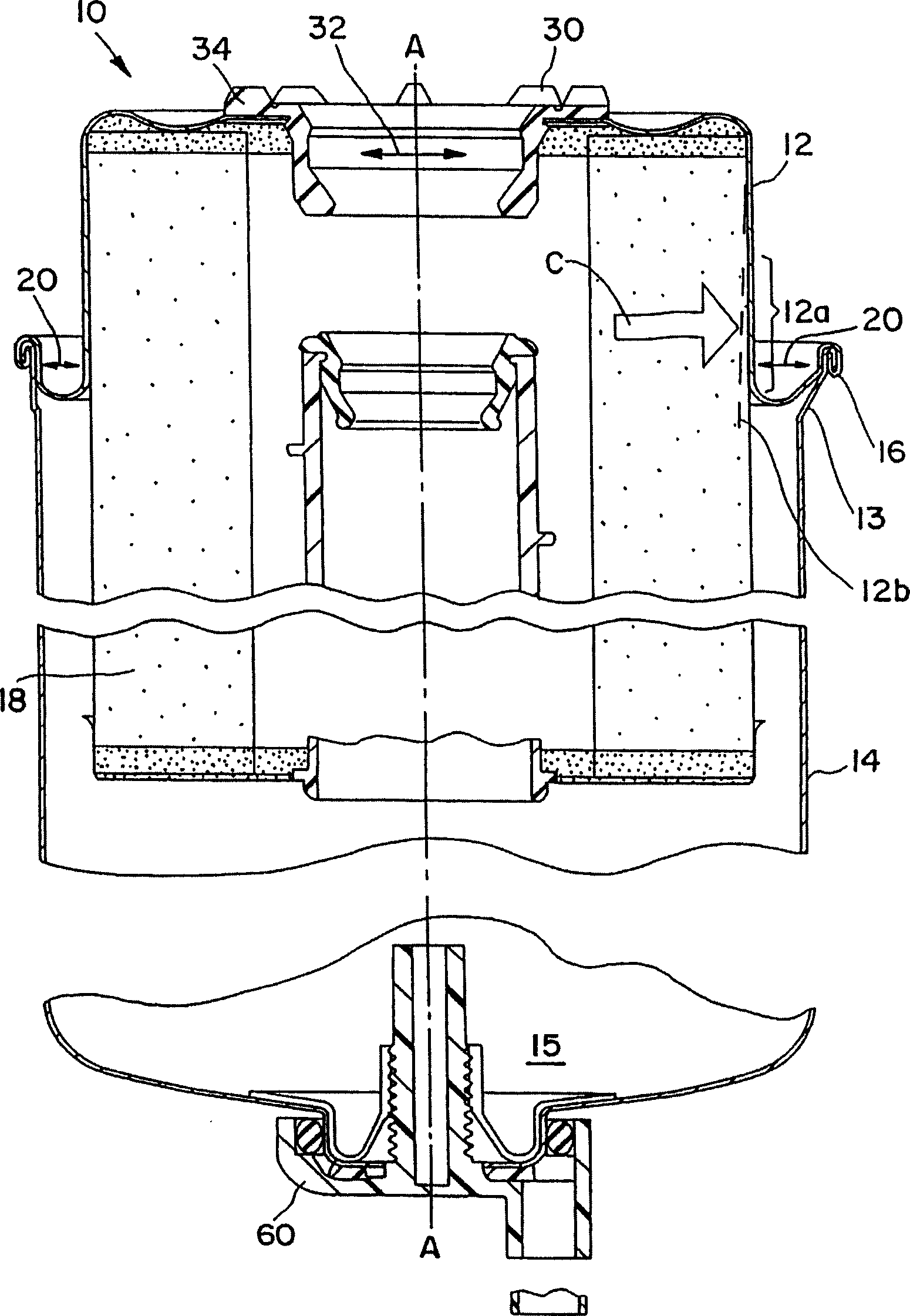

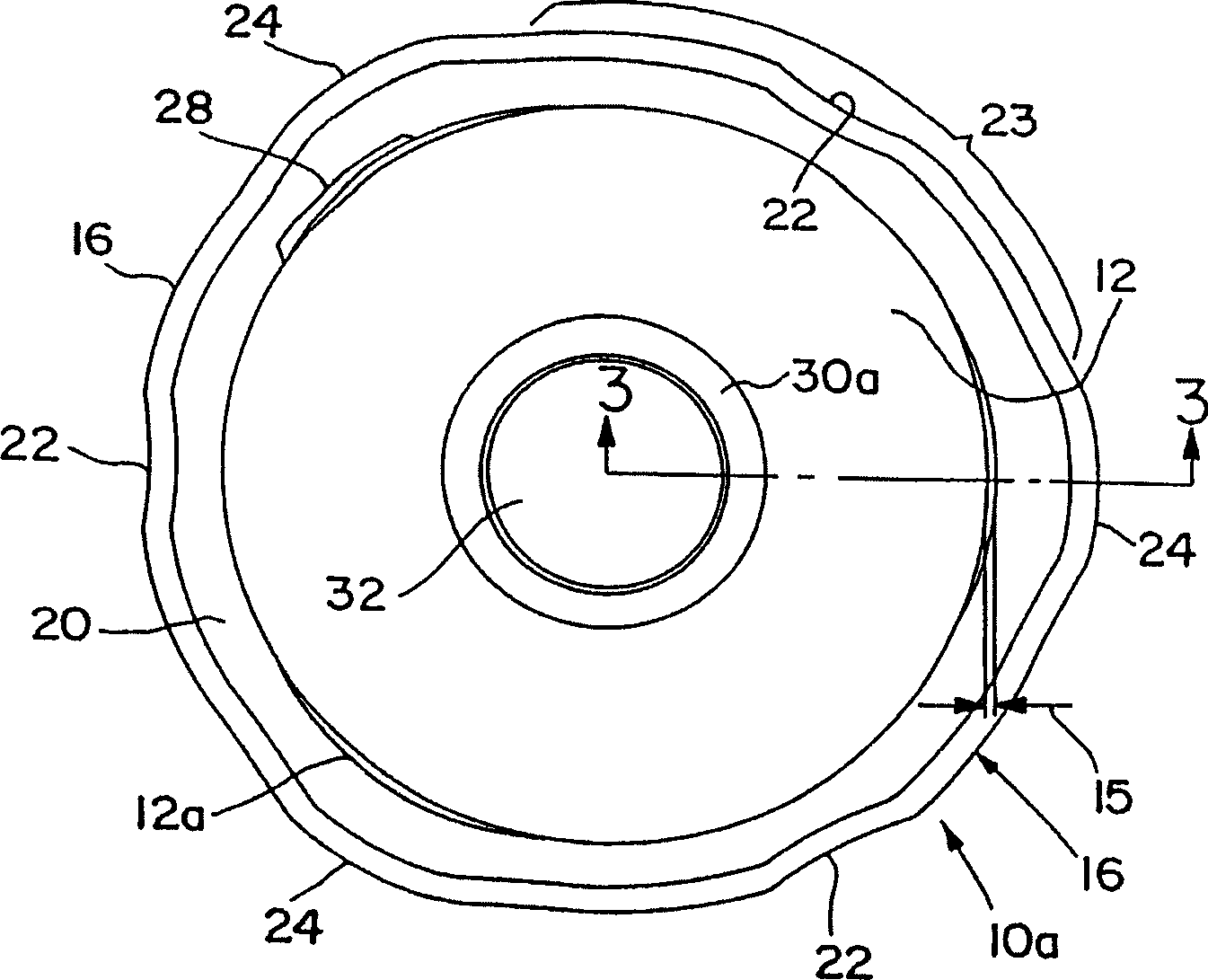

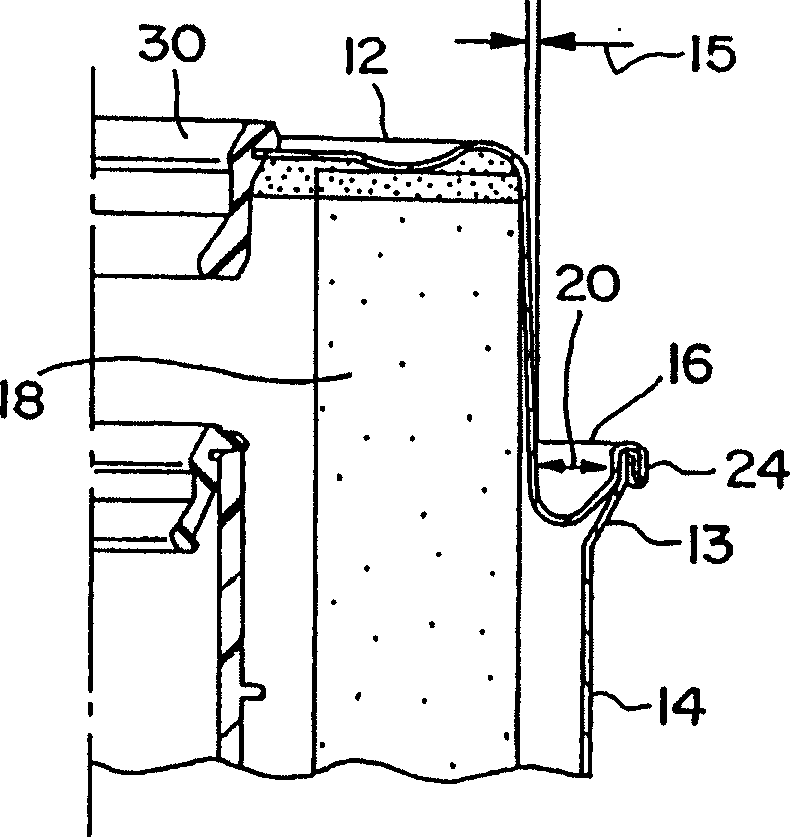

[0025] refer to Figure 1-Figure 3 A typical filter cartridge having features of the present invention is described and marked with the numeral 10. exist Figure 4-Figure 8 expressed in and Figure 1-Figure 3 A specific example of a filter base assembly that fits into the filter cartridge and is marked with the numeral 80. exist Figure 9 and Figure 10 A specific embodiment of a retaining collar suitable for securing the filter cartridge 10 to the base assembly 80 is shown in and marked with the numeral 100.

[0026] figure 1 is a cross-sectional view of a filter cartridge 10 including a first housing portion 12 connected to a second housing portion 14 along a peripheral roll interface. The first housing portion, or end cap 12 has a smaller diameter than the second housing portion 14 . figure 1 Among them, the metal sheets forming the respective housing parts of the rolling interface are indicated by dotted lines around the filter cartridge 10 near the rolling interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com