Anode digestion votammetry

An anode stripping voltammetry and voltage technology, which is applied in the field of polarographic analysis, can solve problems such as low accuracy, high Cu concentration, and decreased sensitivity of polarographic instruments, and achieves extended service life, simple testing process, and shortened enrichment time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

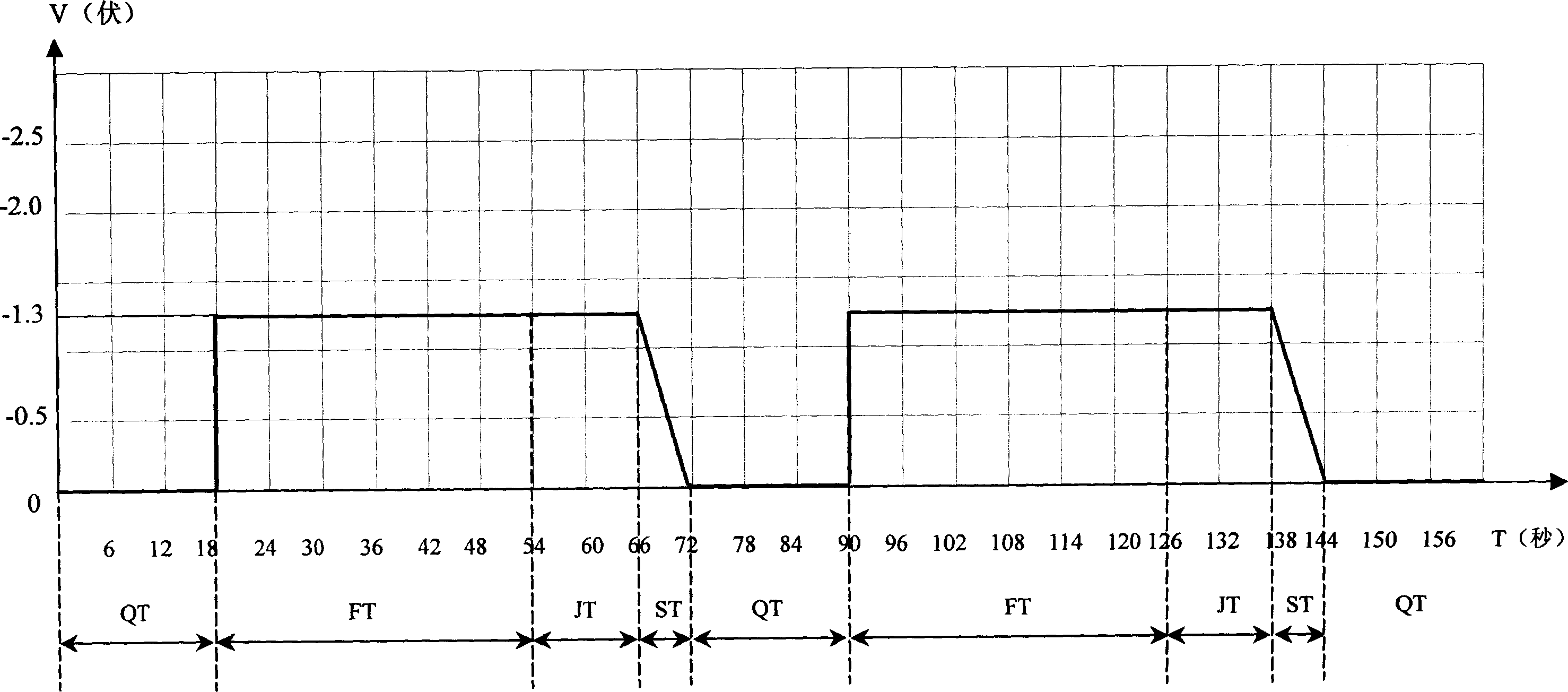

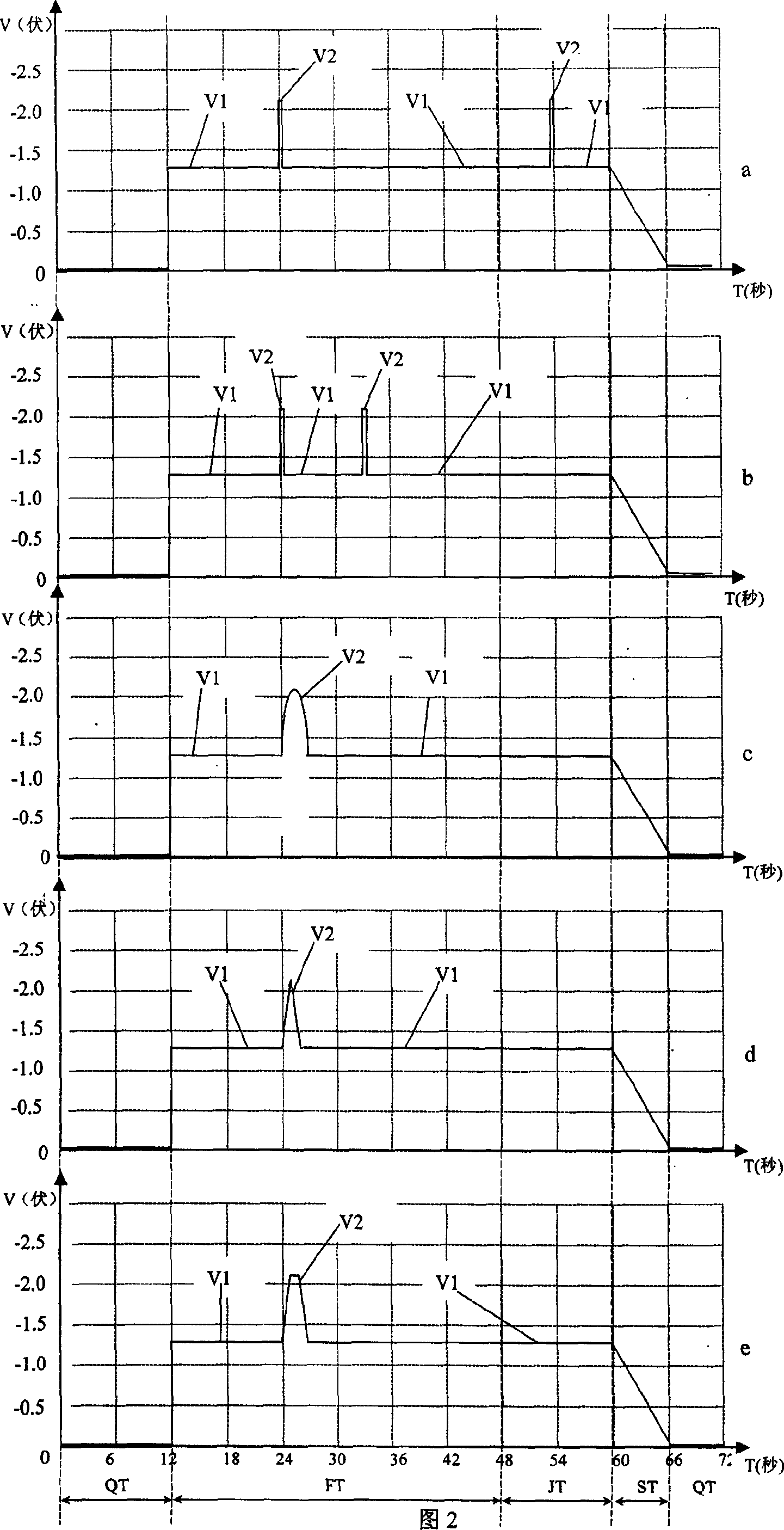

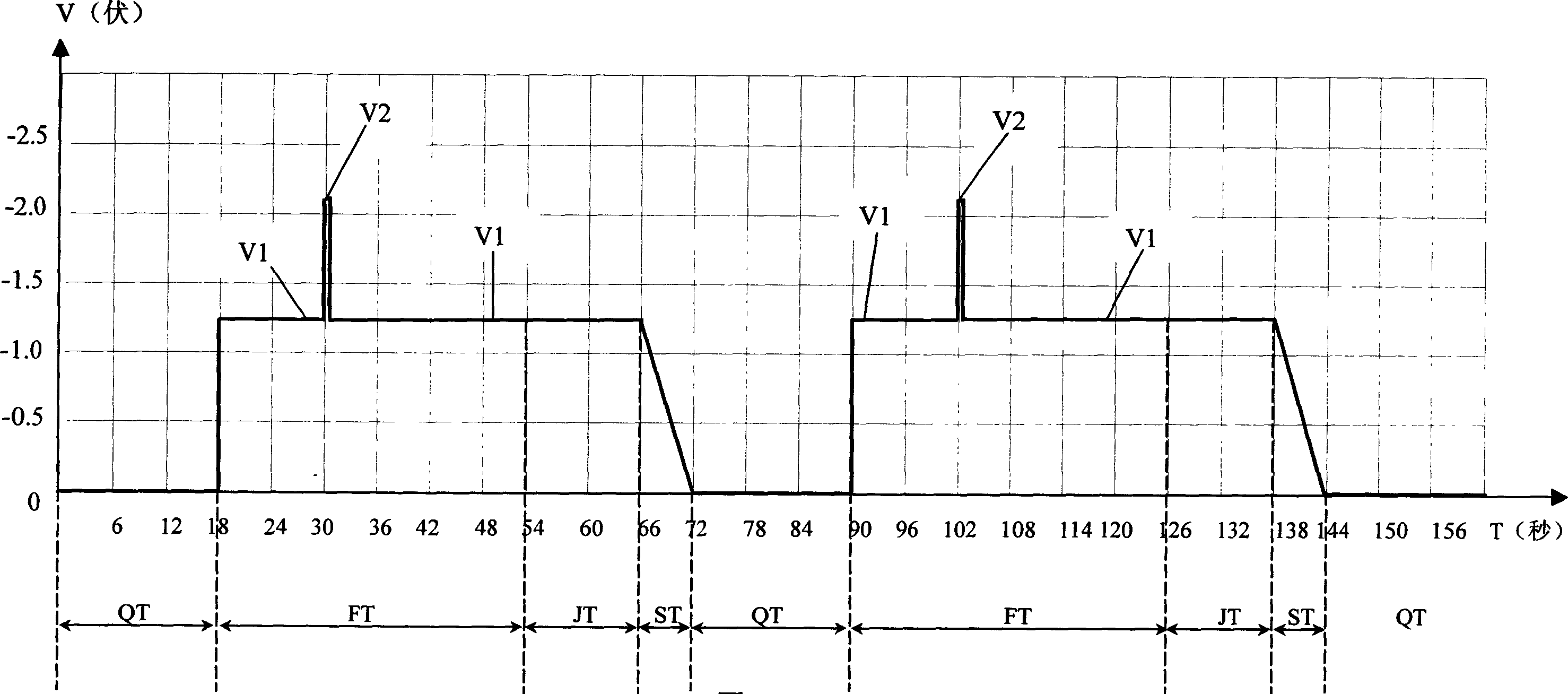

[0033] In order to compare the technical effects of the embodiments of the present invention with the existing anodic stripping voltammetry, before introducing the embodiments of the present invention, at first adopt the existing anodic stripping voltammetry to measure Zn, Zn, Concentration of Cd, Pb, Cu. Existing anodic stripping voltammetry includes four steps of cleaning, enrichment, standing and scanning in each test cycle. The instrument adopts a polarograph whose sensitivity is selected as 10. Mercury-based film working electrode. The waveform diagram of the voltage between the working electrode and the reference electrode of the anode stripping voltammetry as a function of time is shown in figure 1 As shown, the cleaning time QT=18 seconds, the enrichment time FT=36 seconds, the rest time JT=12 seconds, and the scan time ST=6 seconds; both the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com