Insulating flange for connection of ship and shore pipelines

A flange and ship-to-shore technology is applied in the field of improvement of the structure of connecting flanges of ship-to-shore oil pipelines, and can solve the problems of difficult manufacturing process, difficult to guarantee reliability, and limited practical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

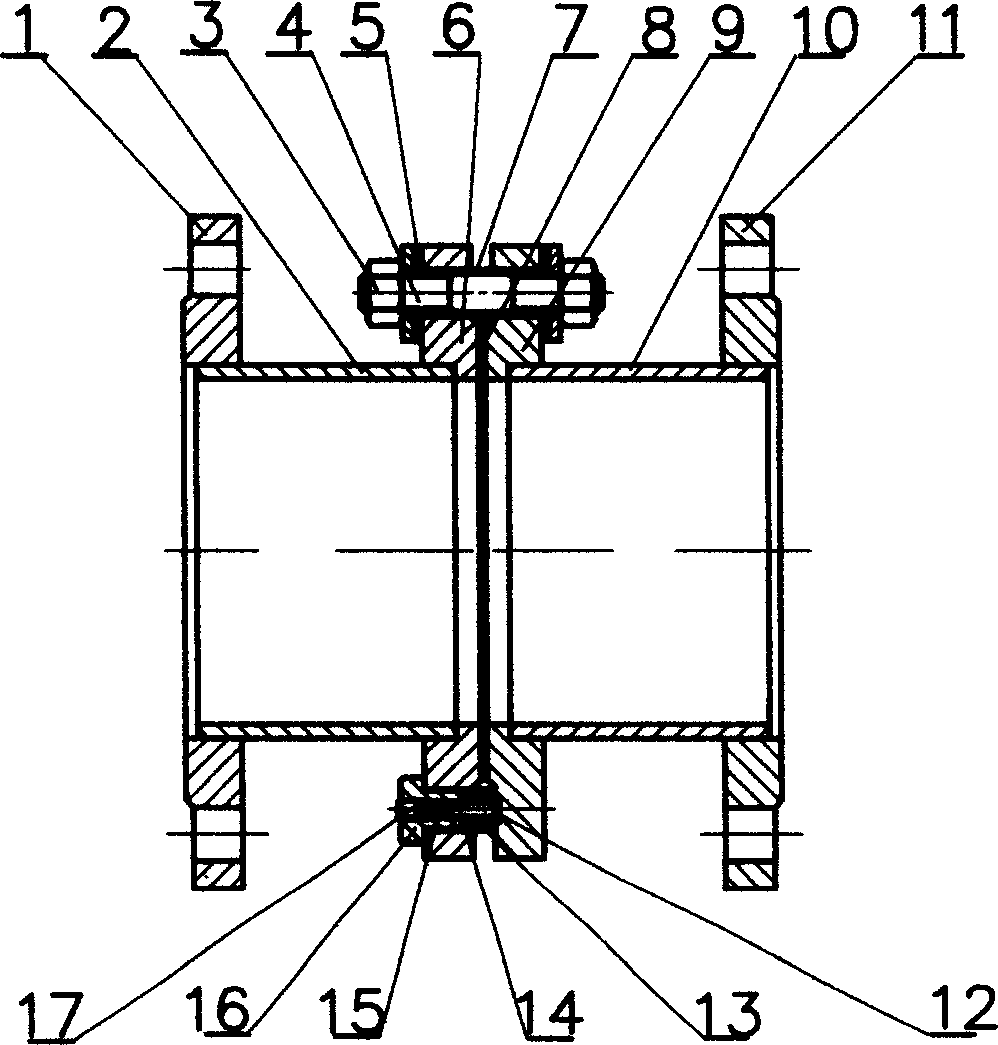

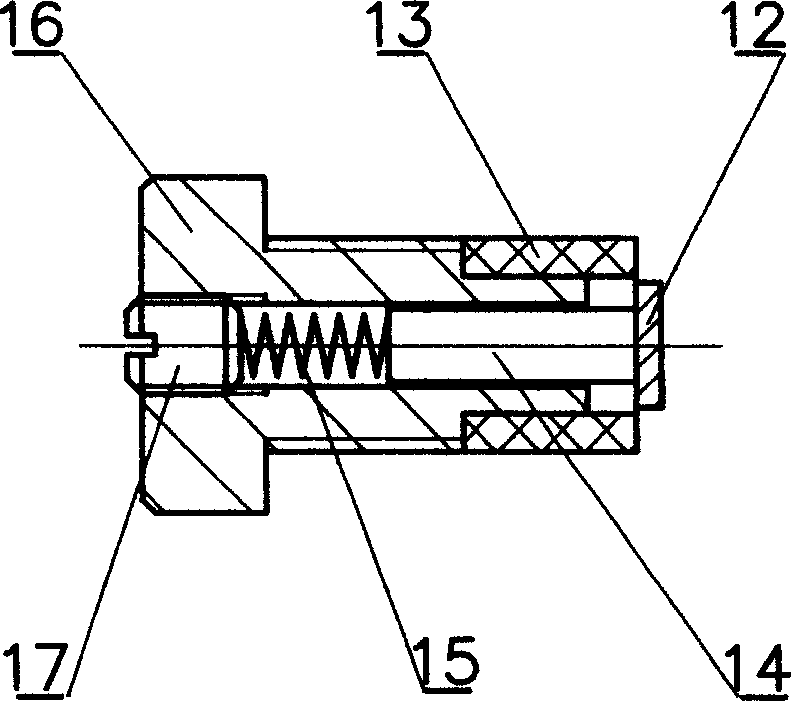

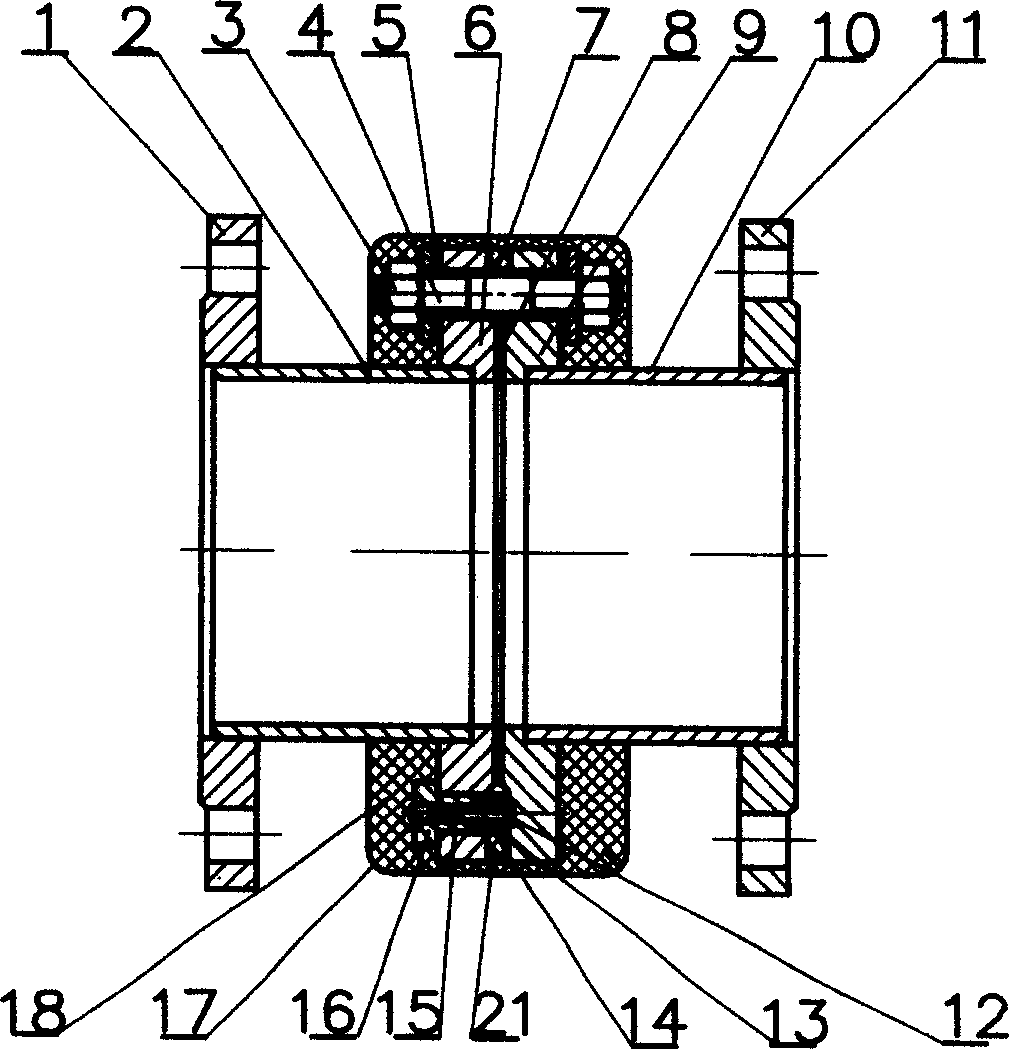

[0017] exist figure 1 , figure 2 In the shown ship-to-shore connection insulating flange, an insulating gasket 8 is placed between the left flange 6 and the right flange 9 of the circular disc structure, and the insulating gasket 8 is made of asbestos with high strength, oil resistance and pressure resistance. Gasket, its resistance value is not less than 109Ω. There are several bolt holes evenly distributed on the surface of the left and right flanges, each bolt hole is pierced with a stud bolt 4 (also a single head bolt), and the left flange 6 and the right flange are connected by the nut washer 3. The flange 9 is locked and connected; the bolt 4 is covered with a bolt insulating sleeve 7, and an insulating gasket 5 is placed between the nut washer 3 on one side of the bolt 4 and the flange, so that the bolt 4 can realize The connection of the left and right flanges is fastened, and the two flanges are kept insulated. The left side short pipe 2 and the right side short p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com