Substrate conveying apparatus for sequence type substrate box

A substrate handling and substrate box technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of reduced space efficiency and large space in clean rooms, and achieve the effect of increasing space efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

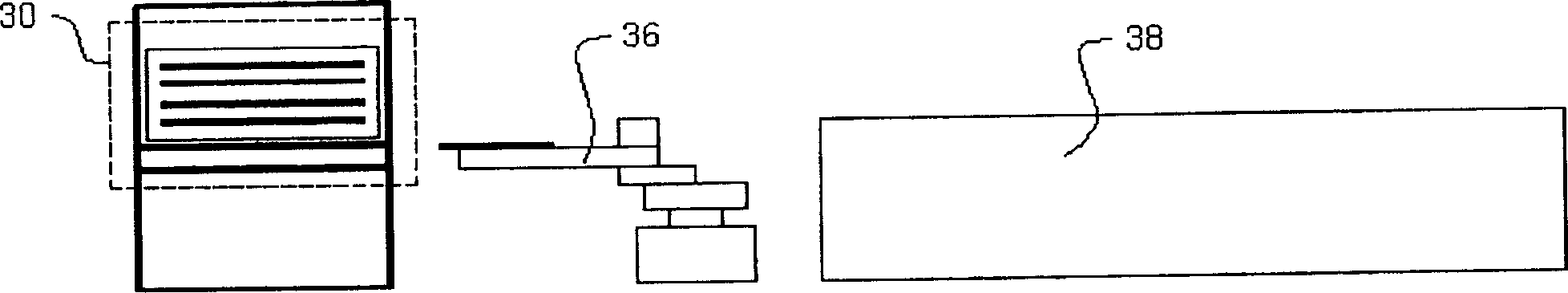

[0045] now refer to Figure 6 , Figure 6 A substrate handling device 50 according to a first embodiment of the present invention is shown, and the substrate handling device 50 is used to load the substrates in a plurality of sequential substrate cassettes into a loading port 62 of a flow processing equipment 60 . The substrate handling device 50 has a plurality of serial substrate cassette holders 72 for accommodating the serial substrate cassettes. The serial substrate cassette seat 72 has driving rollers (not shown in the figure) for sequentially outputting the substrates in the serial substrate cassette. The substrate handling device 50 also has a moving rail 76 arranged along the plurality of sequential substrate cassette holders 72, a receiving conveyor 74 (reception conveyor) movable along the moving rail 76, and a The robot arm 70 moves one end of the track 76 .

[0046]During operation, the serial substrate cassette containing a plurality of substrates is individua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com