Eccentric input material of paste mill in high concentration

A high-consistency refiner and feeding technology, which is used in fiber raw material processing, pulp beating/refining methods, textiles and papermaking, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

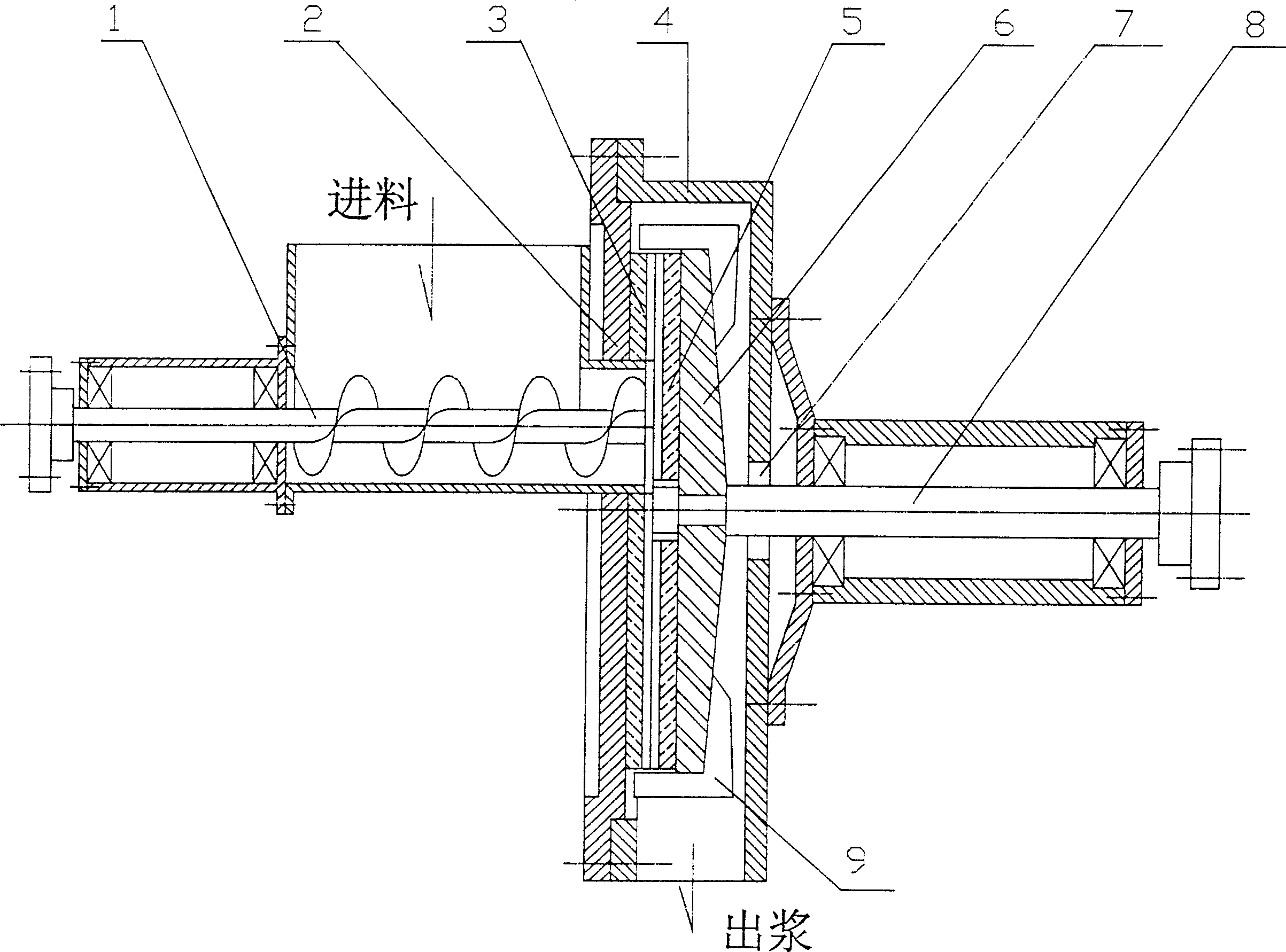

[0010] The embodiments of the eccentric feeding high-consistency refiner of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] In the eccentric feeding high-consistency refiner of the present invention, since the feed hole is provided with a larger eccentricity relative to the center of the rotary grinding plate, the feed hole is aligned with the refining tooth surface of the rotating grinding plate; the high-concentration fiber raw material Driven by the feeding screw, it directly enters between the fixed grinding plate and the rotating grinding plate, and the high-concentration fiber raw material is brought into the plane refining area by the grinding teeth on the rotating grinding plate, and the arc-shaped groove on the fixed grinding plate changes from deep to shallow It can make the bulky high-concentration fiber raw materials easily enter the plane refining zone without relying on the strong pushing of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com