High voltage large capcity breaker

A large-capacity, circuit breaker technology, applied in high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve problems that are difficult to deal with, and achieve the effect of simple structure, good insulation, and high insulation withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below with reference to the drawings.

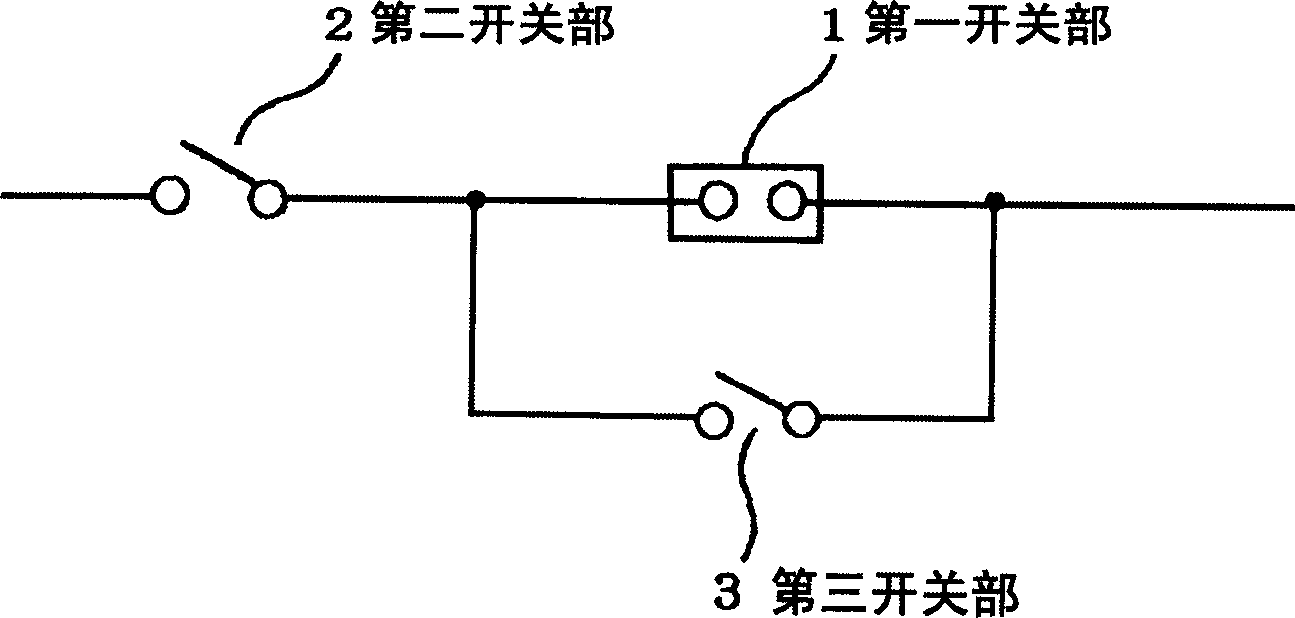

[0021] figure 1 It is a single-line wiring diagram of a high-voltage large-capacity circuit breaker showing an embodiment of the present invention.

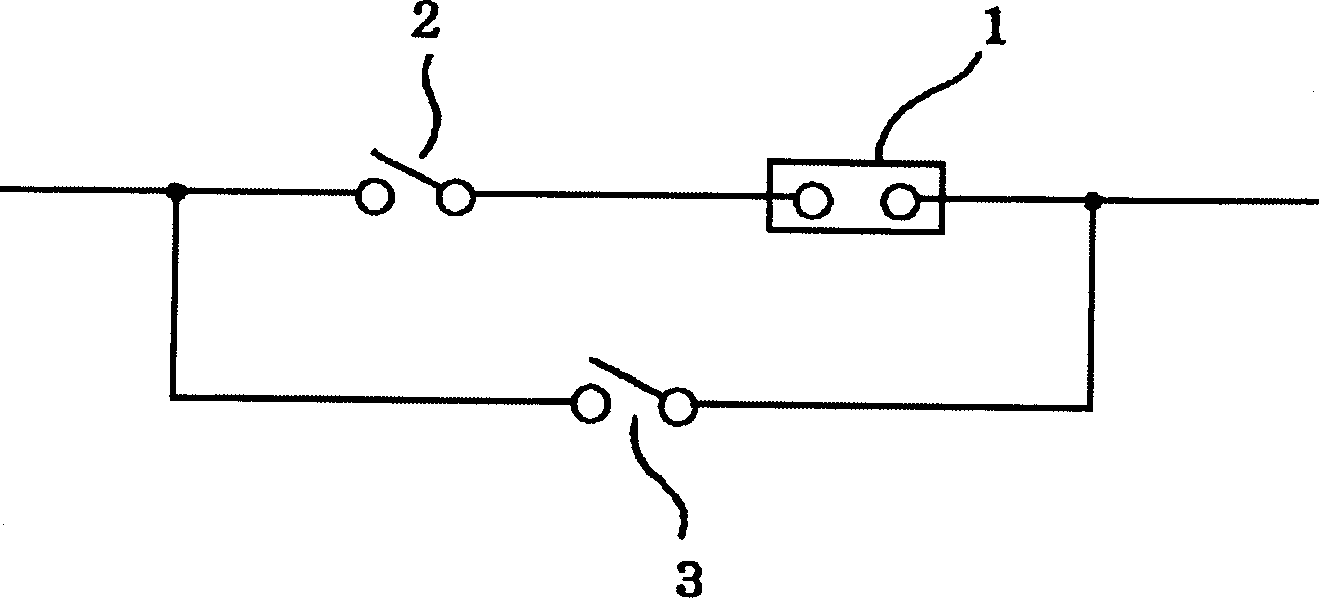

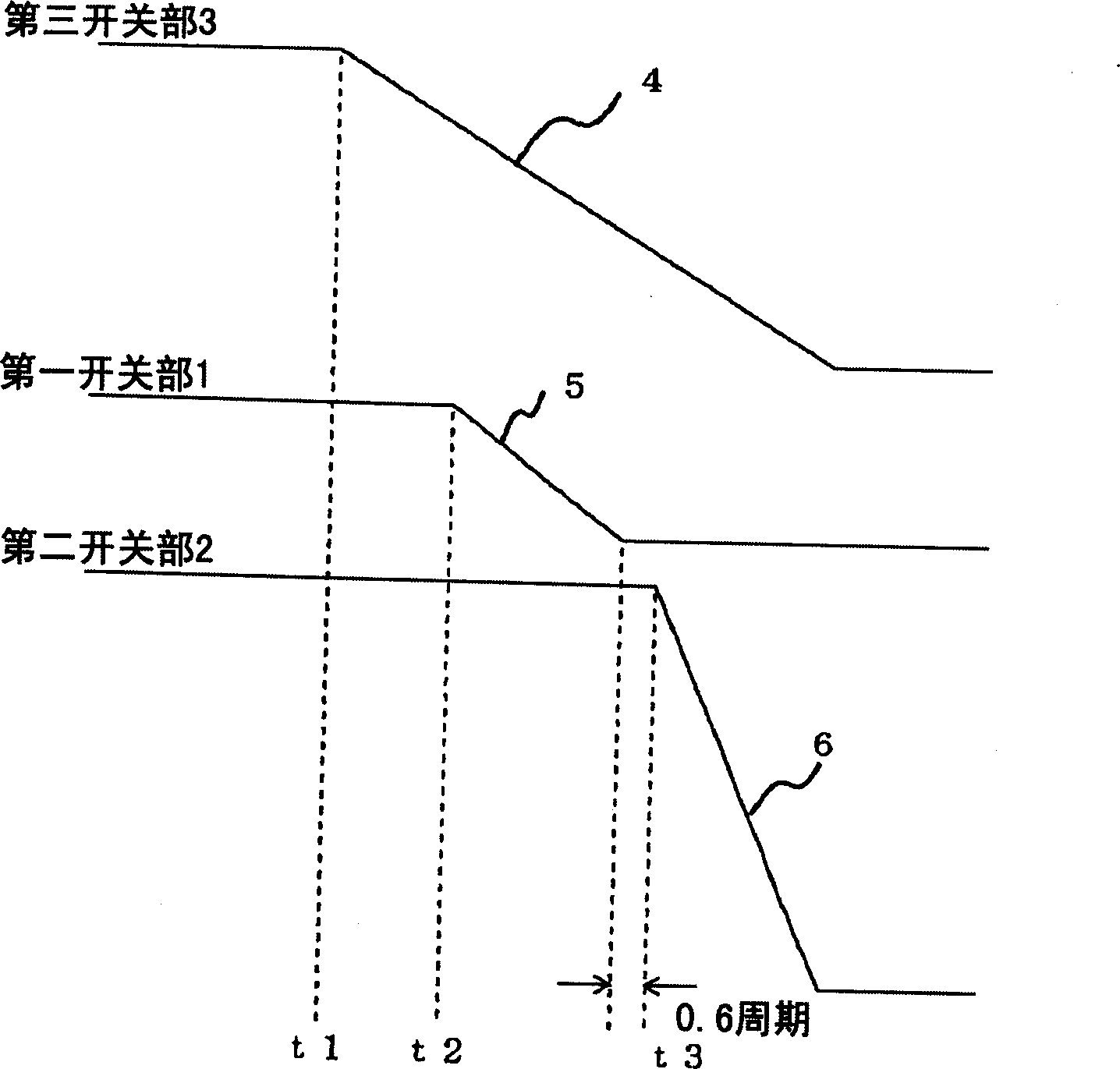

[0022] The components constituting the high-voltage large-capacity circuit breaker include: a first switch unit 1 ; a second switch unit 2 electrically connected in series with the first switch unit 1 , and a third switch unit 3 electrically connected in parallel with the first switch unit 1 . The first switch unit 1 is constituted by a vacuum interrupter having excellent current interruption characteristics for separating electrodes in a vacuum to interrupt current. On the other hand, the second switch unit 2 has a structure in which the contacts are separated in an insulating medium other than a vacuum, for example, in an insulating gas. After the current cut off by the first switch unit 1, the contacts The head is spaced apa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com