Separating equipment for soliquoid

A technology for separation equipment and suspensions, applied in solid separation, wet separation, separation devices, etc., can solve the problems of sediment deposition and unevenness, and achieve the effects of preventing gas accumulation, reducing operating costs, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

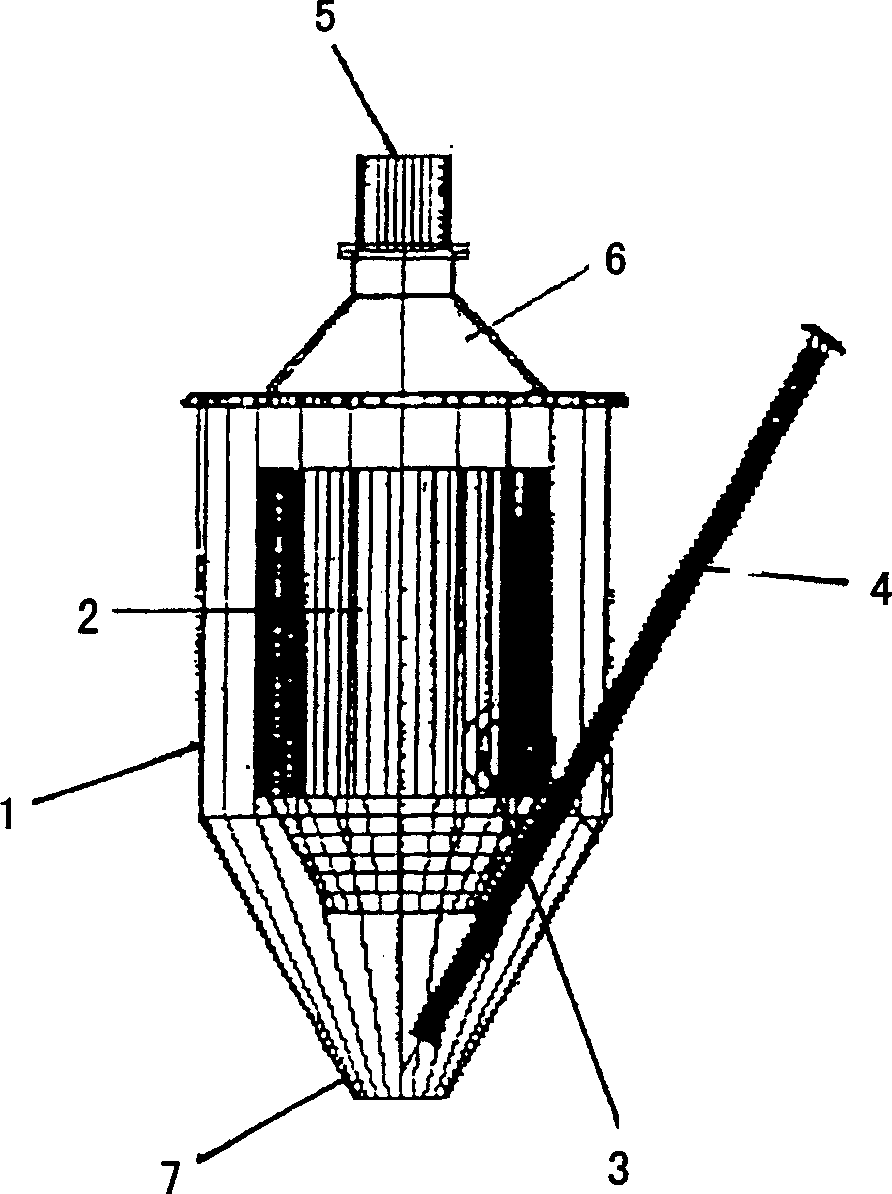

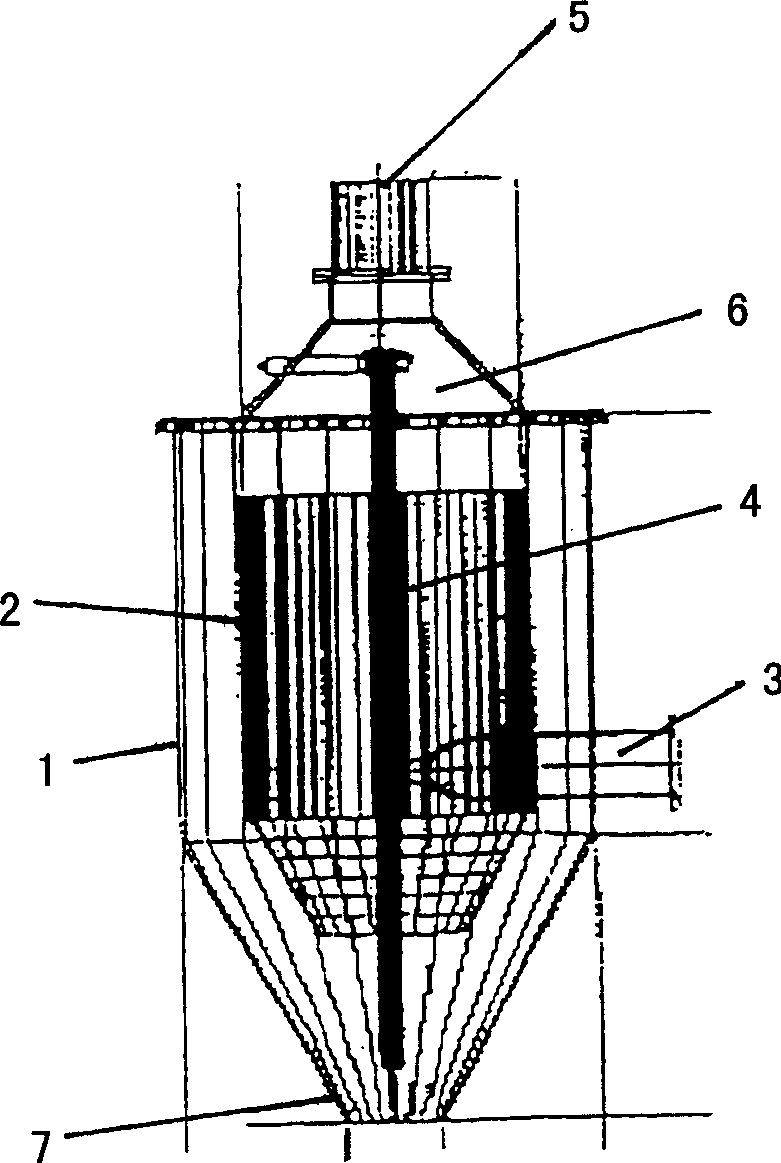

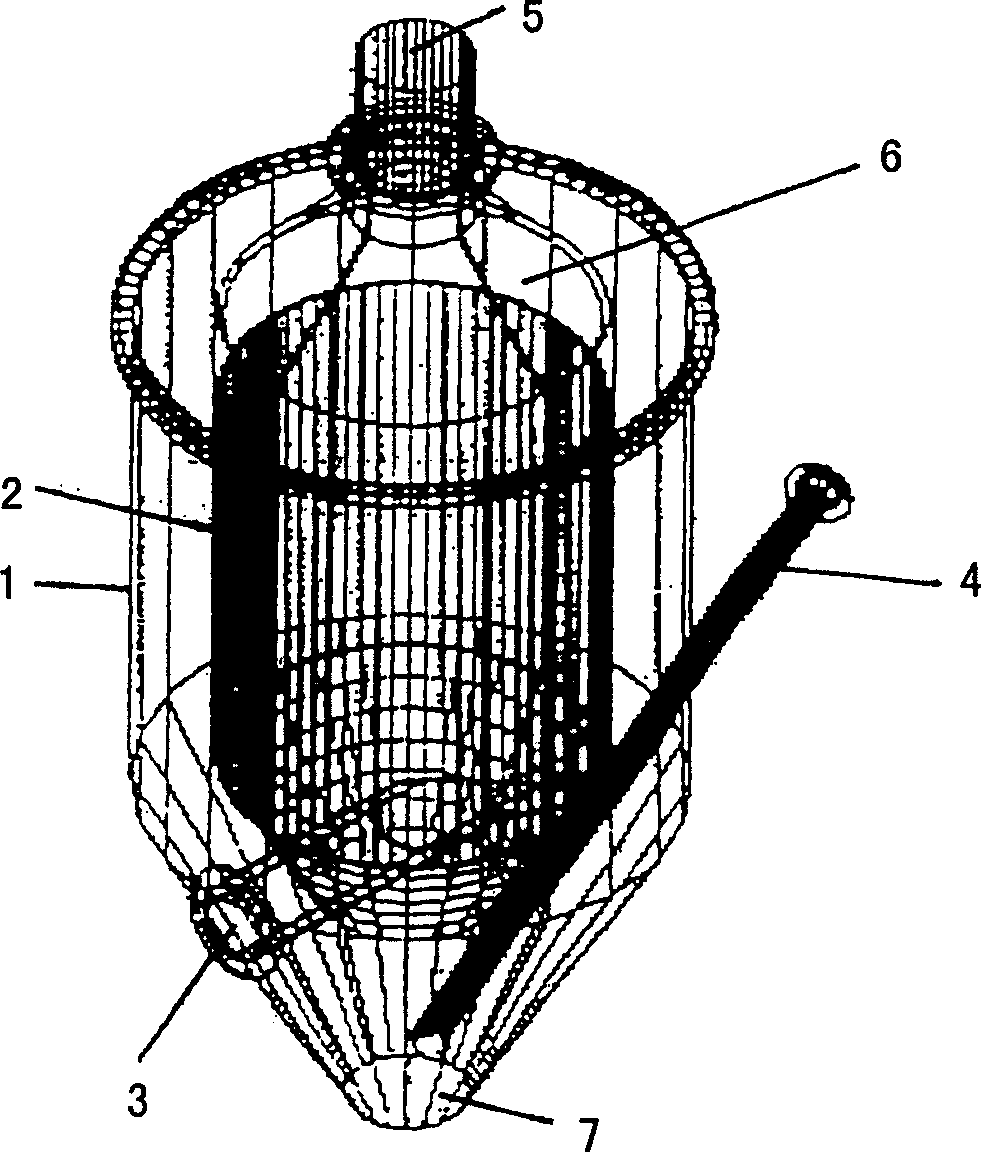

[0026] Each of these figures shows a different view of the same separation device. exist figure 1 In , the parts of the separation equipment are marked with reference numerals. The separating device has an outer base body 1 in which an inner body 2 is arranged. The base body 1 and the inner body 2 have an essentially cylindrical shape. The base body 1 is provided here with a conical bottom and a funnel tip 7 . The inner body 2 has a cone which is open downwards. Such as figure 2 As shown, the inlet 3 for the suspension is arranged eccentrically and constricts into a nozzle according to the permissible pressure loss. Discharge 5 for liquids containing hard-to-settle solids is arranged in the upper cover 6 . The cap 6 is conical and matches the diameter of the inner body 2 at the end. To optimize accessibility, the cover 6 is removable in one piece. In the conical bottom region of the base body 1 there is an outlet 4 for sludge containing easily settled solids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com