Container body partial heat-insulating layer foaming method

A technology for thermal insulation layer and container, which is applied in the foaming field of forming thermal insulation layer, can solve the problems of potential safety hazards, inconvenient injection operation, unbalanced pressure, etc., and achieve the effect of ensuring strength, convenient injection operation and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

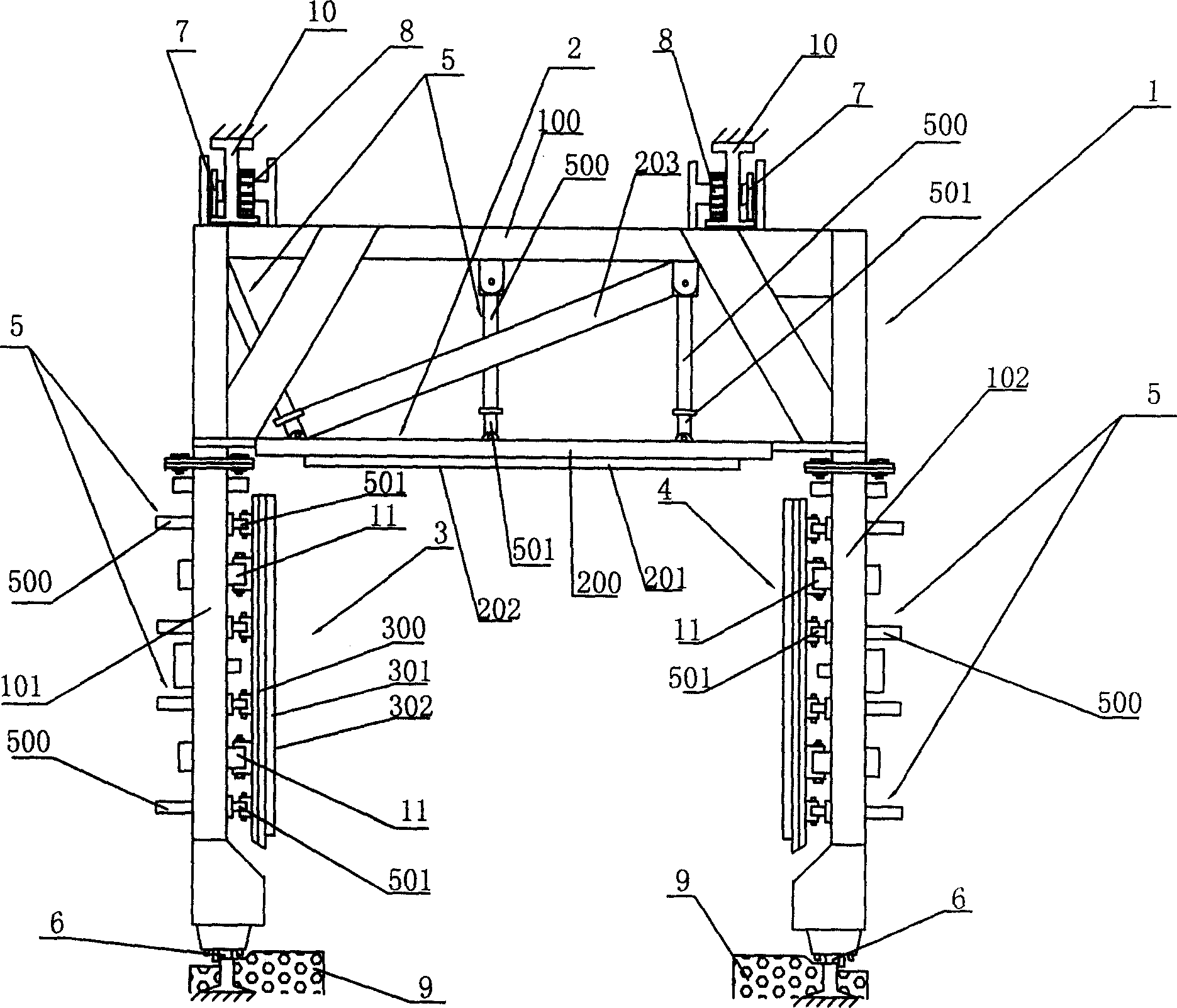

[0017] Embodiment 1, taking the case of repairing the partially damaged insulation layer of the side panel of the container body as an example, a foaming method for the local insulation layer of the container box body, which is carried out according to the following steps: Measure the bubble area and calculate its volume V. According to the standard density R, such as the required density of the box side plate is generally 40-50 kg / m3, calculate the required mass of liquid foaming material as the selected amount of injection material. Foaming holes and venting hole groups are set on the horizontal line of the outer wall plate corresponding to the commanding height of the foaming area, and each foaming hole and venting hole group is provided with one foaming hole and two venting holes. Located at the center between the two vent holes, the vent holes are respectively set at the left and right edge endpoints of the commanding height horizontal line of the foaming area. Inject the...

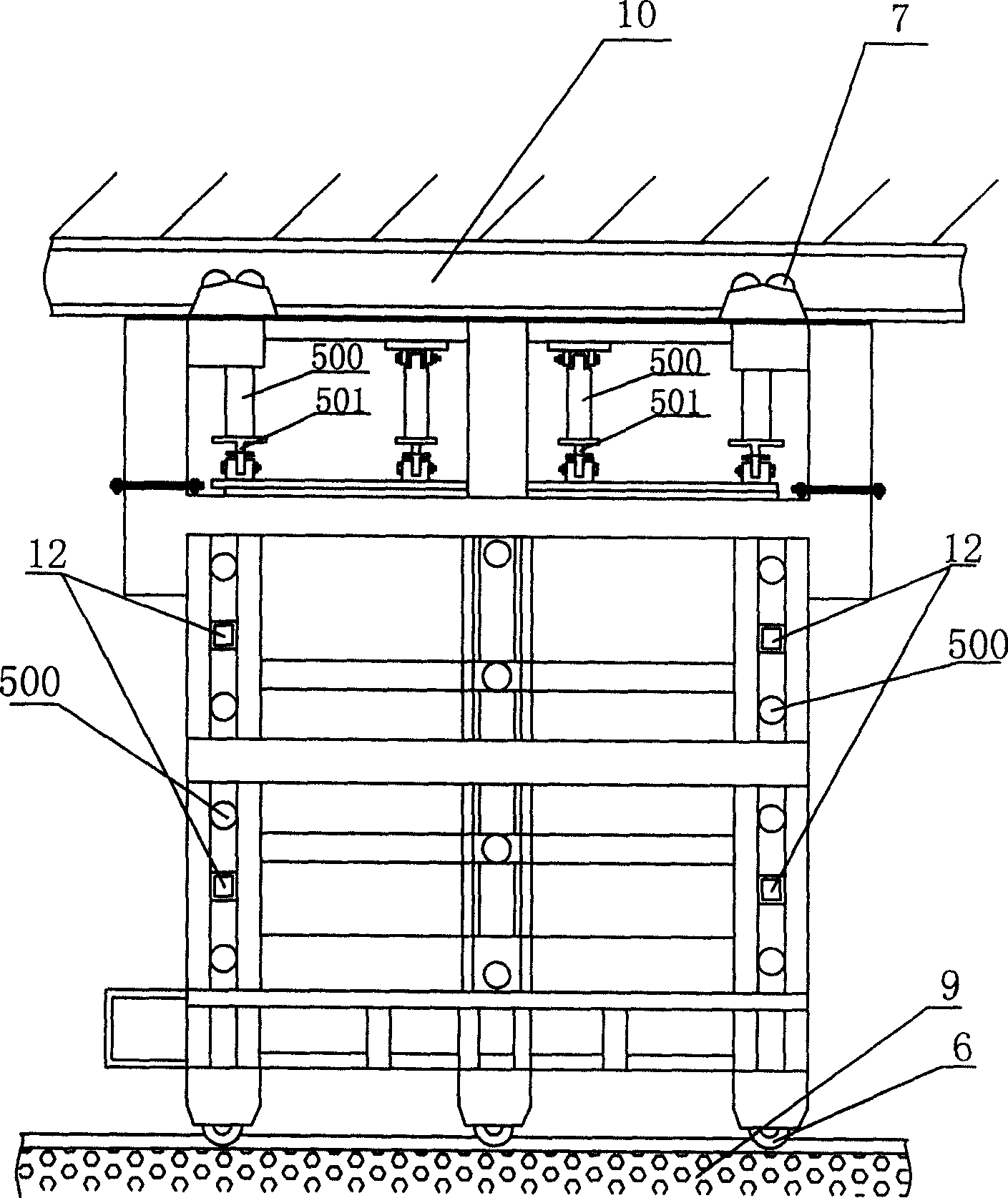

Embodiment approach 2

[0018] Embodiment 2, taking the case of repairing a partially damaged insulation layer on the roof of a container as an example, a foaming method for a partially damaged insulation layer of a container box, which is carried out according to the following steps: Measure and calculate its volume V. According to the standard density R such as the required density of the box top plate is generally 50-55 kg / m3, calculate the required quality liquid foaming material as the selected amount of injection material. When the top plate is placed horizontally, at the commanding height of the foaming area corresponding to the left or right end face of the top plate, a group of foaming holes and exhaust holes are set on the horizontal line along the edge of the length direction of the side wall plate, and each foaming hole and exhaust hole A foaming hole and two venting holes are arranged in the hole group, the foaming hole is located in the center between the two venting holes, and the venti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com