Gas-liquid mixed multi-piston disk brake system

A disc brake, gas-liquid mixing technology, applied in the direction of hydraulic brake transmission, etc., can solve the problems of long working time of the brake system, placement of the brake, large structural size, etc., to achieve thermal stability and water wading Good recovery, short braking reaction time and constant braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

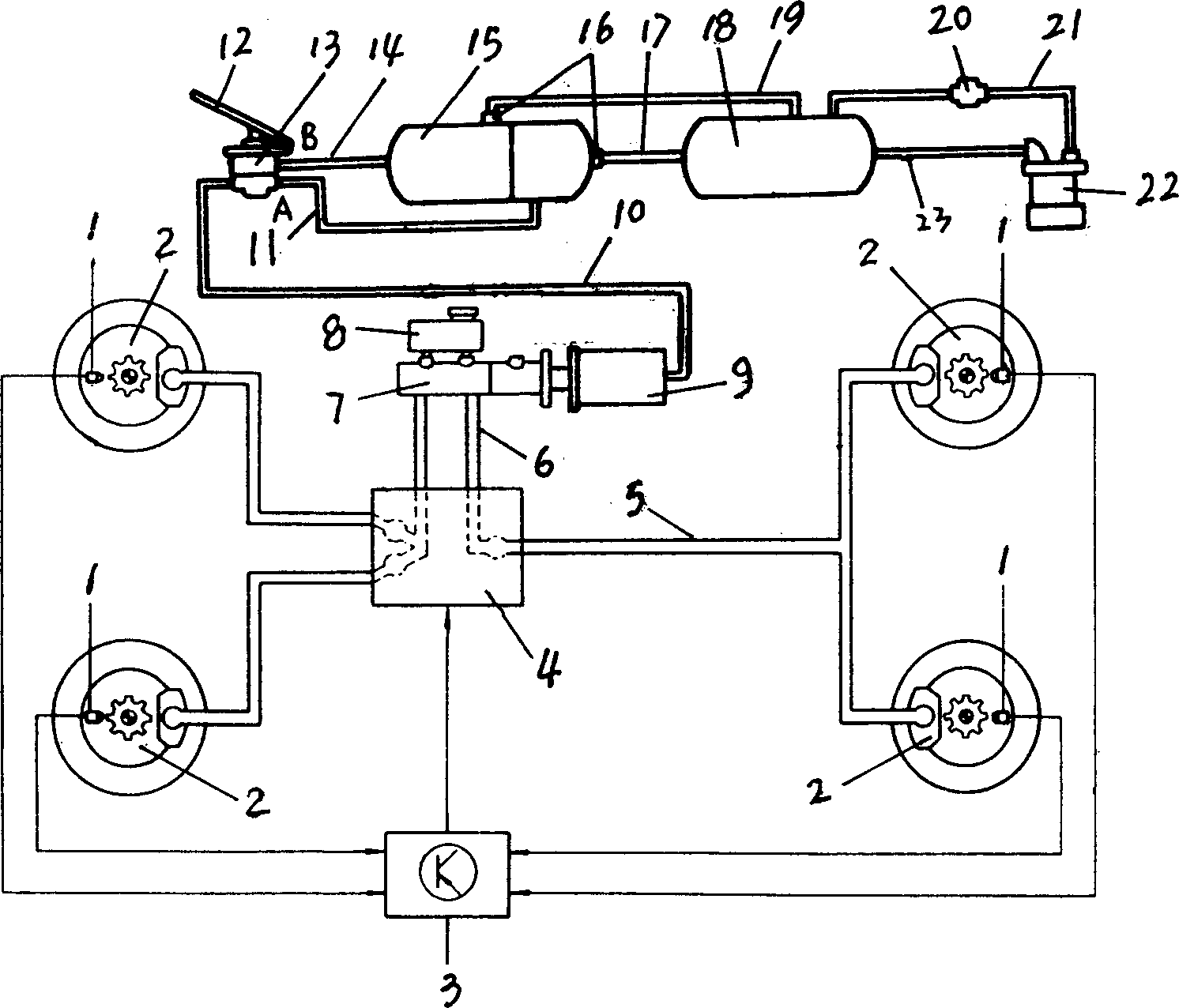

[0012] Such as figure 1 As shown, the gas-liquid mixing multi-live plug type brake system includes a multi-live plug hydraulic disc brake 2, a dispensing valve 4, a hydraulic main pump 7, a reservoir 8, a power chamber 9, a brake pedal 12, a gas pressure brake The control valve 13, the second storage barrel 15, the first gas cylinder 18, the air pump 22, the air passage of the air pump 22 is connected to the first storage cylinder 18, and there is a tuning on the sixth intake pipe 21 The pressure valve 20 is connected to the first storage cylinder 18 by the gas valve 20, and the first storage cylinder 18 is connected to the second storage barrel 15 by the fifth intake pipe 19, the fourth intake pipe 17, respectively. Pass, the fifth intake pipe 19, and the output port of the two mutually independent air chambers of the second storage gas barrel 15 is respectively provided by the second intake pipe 11 and the third intake pipe, respectively. 14 Connecting the input port A of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com