Acarus-proof antibiotic cellulose fiber

A cellulose fiber and anti-mite technology, applied in the field of cellulose fibers, can solve the problems of affecting the durability of the anti-mite effect, high production cost, complicated process, etc., and achieve the effects of good anti-mite effect, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

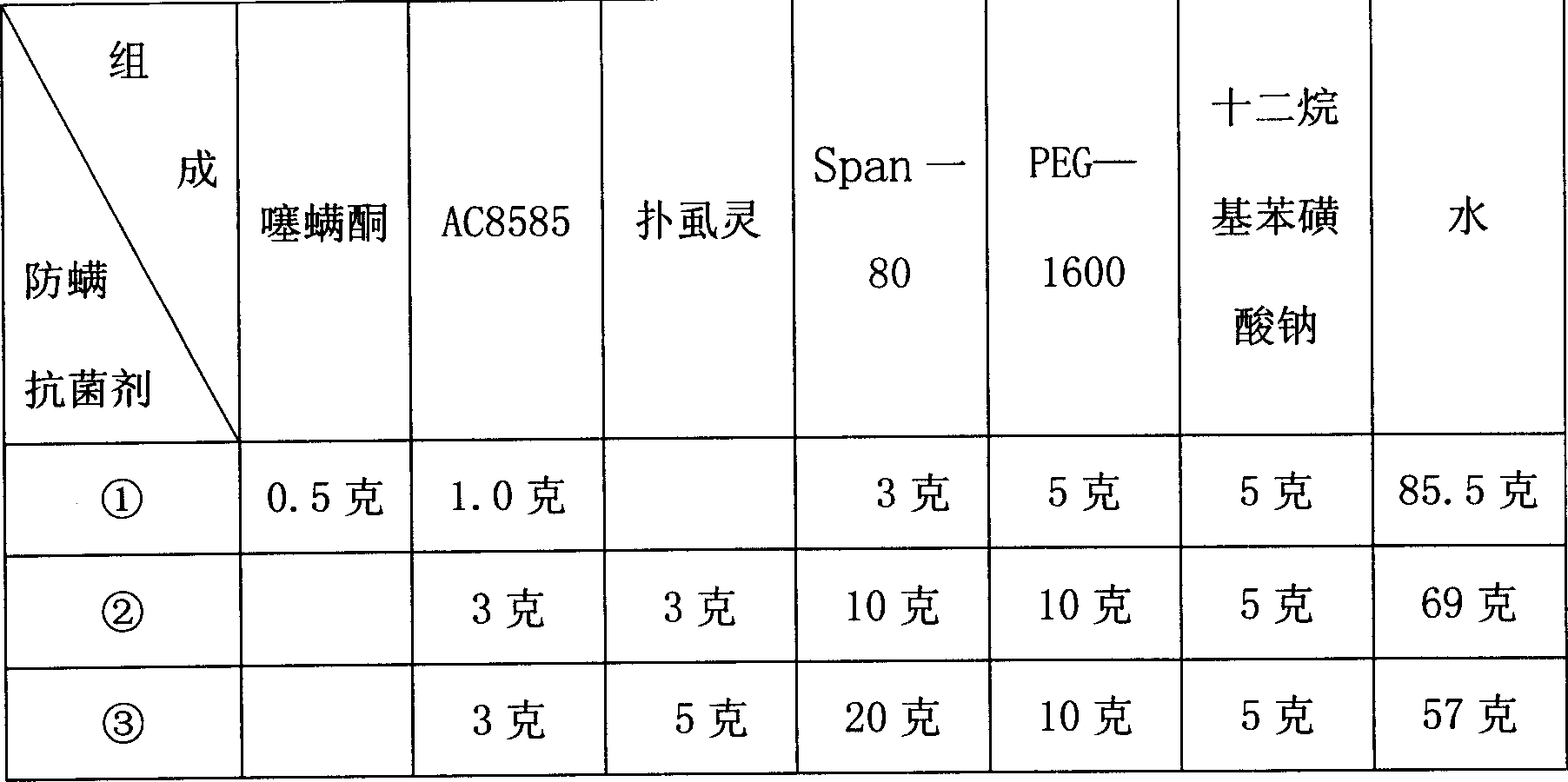

[0006] The following table 1 provides the specific formulations of three anti-mite antibacterial agents:

[0007] Table 1 anti-mite antibacterial agent formula

[0008]

[0009] The following table 2 provides the specific blending ratios of the above three anti-mite antibacterial agents and cellulose (a-Cell), forming nine kinds of anti-mite antibacterial cellulose fiber embodiments:

[0010] Blend ratio

[0011] The nine anti-mite and anti-bacterial fibers obtained by spinning according to the above ratios were tested for anti-mite effects. The detection method of the anti-mite effect was based on the "Anti-mite Fabric Avoidance Test Method" formulated by the Japan Clothing Products Quality and Performance Countermeasures Association in 1998. The test results See the table below:

[0012] The sequence of anti-mite viscose fiber

[0013] The above table shows that the anti-mite and antibacterial fiber of the present invention has good anti-mite effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com