Disc micromechanical top based on acoustic levitation

A micromachined gyroscope and acoustic levitation technology, which is applied in the direction of rotating gyroscope and gyroscopic effect for speed measurement, measurement device, etc., can solve the problems of low precision and efficiency, complex structure, etc. Weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

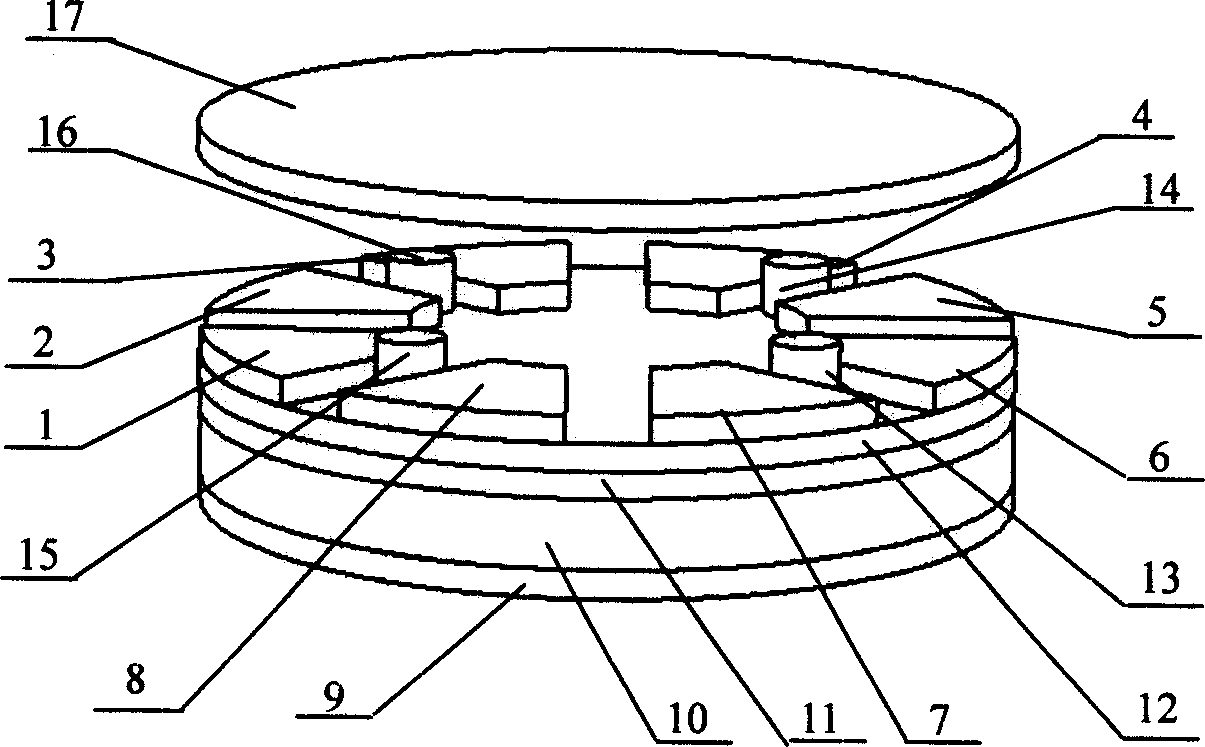

[0012] like figure 1 As shown, the present invention includes: eight capacitor plates 1, 2, 3, 4, 5, 6, 7, 8, partition electrodes 9, piezoelectric plates 10, base electrodes 11, insulating layers 12, and four support columns 13 . . 15, 16 on.

[0013] Capacitance plates 3, 8, 7, 4 and micro rotor 17 are combined to detect the left and right deflection angles of the micro rotor; capacitor plates 2, 1, 6, 5 and micro rotor 17 are combined to detect the front and rear deflection angles of the micro rotor.

[0014] The four supporting columns 13, 14, 15, 16 are all columnar. The support column is to prevent the contact and collision between the micro-rotor and the capacitor plate.

[0015] The piezoelectric plate 10 is polarized along the thickness direction.

[0016] The micro-rotor 17 is a circular metal disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com