Self-sealing type deep-sea pressure-tight sampling control valve

A sampling control, deep-sea technology, applied in sampling devices and other directions, can solve problems such as high cost, reduce pressure holding effect, affect sampling operation, etc., achieve the requirements of reducing installation and stroke accuracy, prevent structural damage, and avoid the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

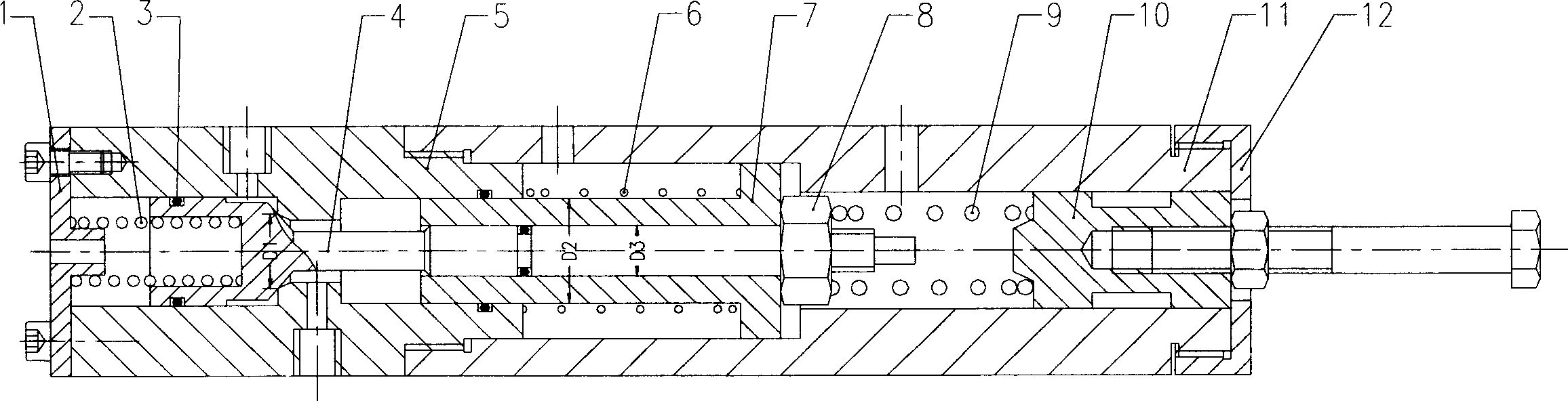

[0013] Such as figure 1 As shown, the present invention includes: spring seat 1, preload spring 2, O-shaped sealing ring 3, valve core rod 4, valve body 5, piston return spring 6, piston 7, limit nut 8, drive spring 9, drive Block 10, sleeve 11, end cover 12, O-ring seal 3 is arranged in the valve core rod 4, valve core rod 4, preload spring 2 and spring seat 1 are arranged in the valve body 5 in sequence, and the outside of the piston 7 is provided with There is a piston return spring 6, the piston 7 is set on the valve core rod 4, the limit nut 8 is set on the top of the valve core rod 4, one end of the sleeve 11 is set on the piston 7 and the piston return spring 6 and connected with the valve body 5 , the other end is provided with a driving spring 9 and a driving block 10 and is provided with an end cover 12 .

[0014] Except for the sealing of the valve port of the valve body 5 and the sealing structure formed by the piston 7, the valve body 5 and the valve core rod 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com