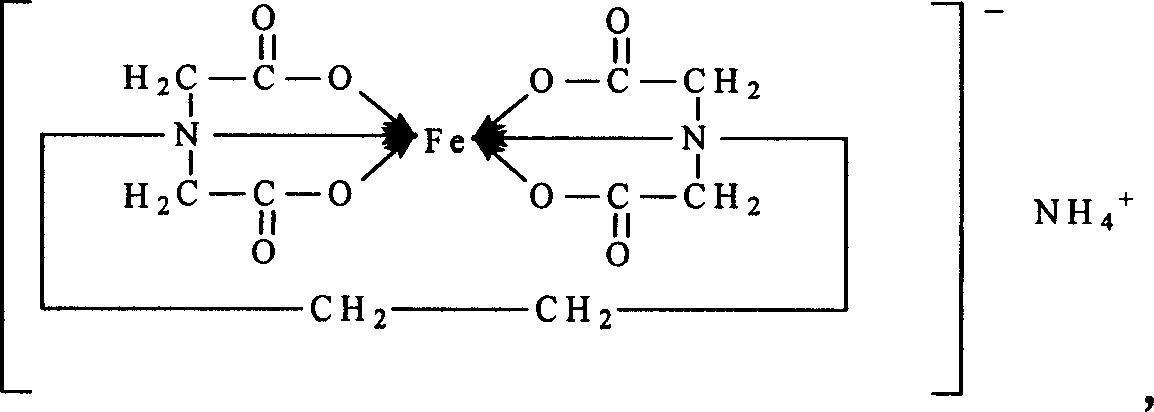

Preparation method of high concentration ferric ammonium ethylene diamine tetraacetate solution

A ferric ammonium ethylenediamine tetraacetate, high-concentration technology, applied in the directions of photography, optics, instruments, etc., can solve the problems of high energy consumption, long reaction time and high cost, and achieve fast reaction, fast preparation speed and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take H at a molar ratio of 1:1 4 EDTA and concentrated NH 4 OH (25%) was reacted in a 700w microwave reactor for 5 minutes, the aeration rate was kept at 0.08L / min, and the reaction produced NH 4 h 3 EDTA, then joined with H 4 EDTA and Fe powder with a particle size of 0.08 mm in a microwave reactor and NH 4 h 3 EDTA reacted for 60min to obtain NH with a concentration of 48% 4 solution of FeEDTA.

Embodiment 2

[0025] Take H at a molar ratio of 1:1.1 4 EDTA and concentrated NH 4 OH (25%) was reacted in a 700w microwave reactor for 5 minutes, the aeration rate was kept at 0.06L / min, and the reaction produced NH 4 h 3 EDTA, then joined with H 4 EDTA and Fe powder with a particle size of 0.08 mm in a microwave reactor and NH 4 h 3 EDTA was reacted for 40 minutes to obtain NH with a concentration of 46%. 4 solution of FeEDTA.

Embodiment 3

[0027] Take H at a molar ratio of 1:1.2 4 EDTA and concentrated NH 4 OH (25%) was reacted in a 700W microwave reactor for 5 minutes, the aeration rate was kept at 0.04L / min, and the reaction produced NH 4 h 3 EDTA, then joined with H 4 EDTA and Fe powder with a particle size of 0.12 mm in a microwave reactor and NH 4 h 3 EDTA was reacted for 40 minutes to obtain NH with a concentration of 45%. 4 solution of FeEDTA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com