Textile machinery with air flow delivery unit and filtering unit

A technology of textile machinery and air conveying, which is applied in the direction of continuous winding spinning machine, spinning machine, textile and paper making, etc., can solve the problems of pollution, loss of filtering effect, influence of wool yarn, etc., and achieves low cost and simple geometry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

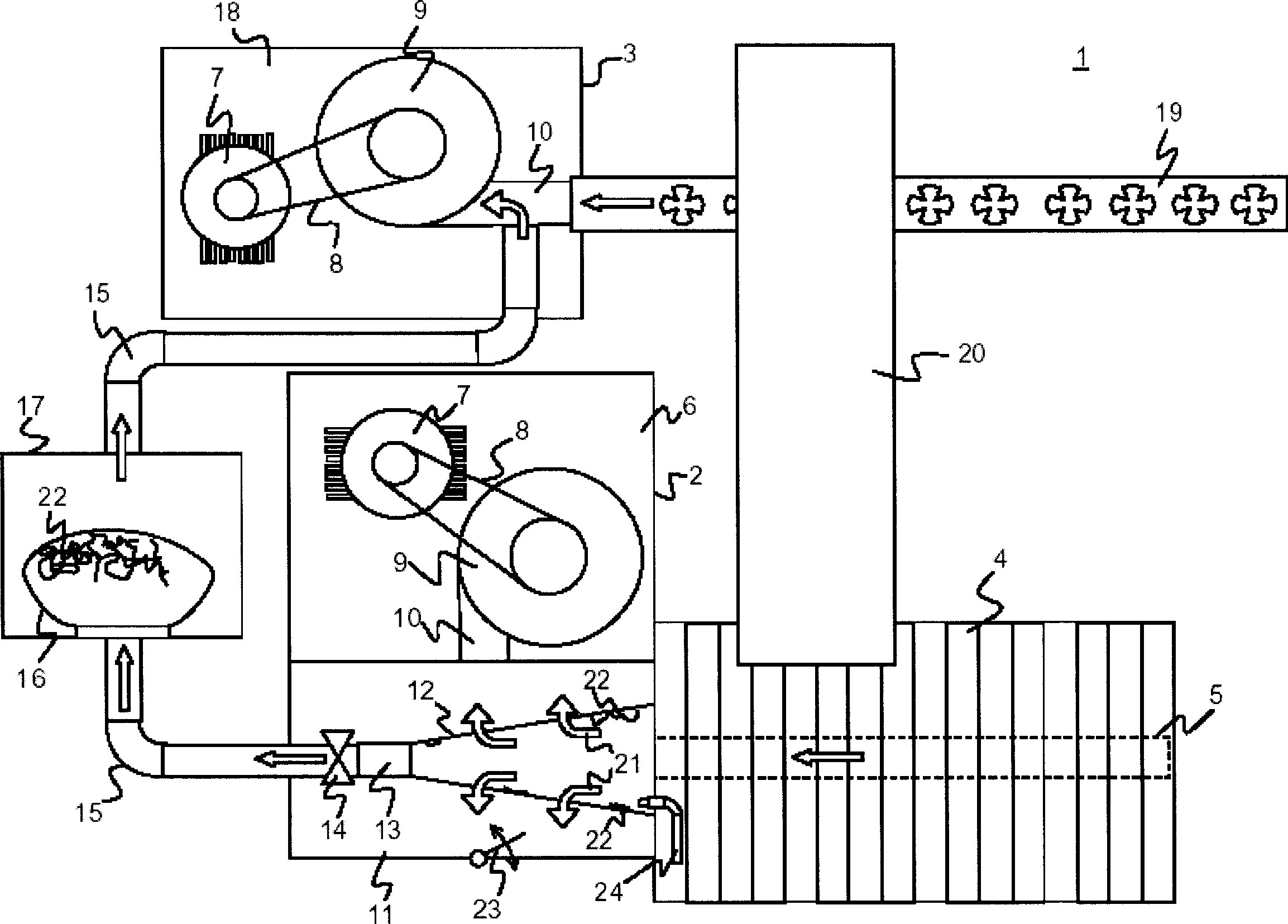

[0039] figure 1 A possible embodiment of the textile machine 1 of the invention is given in . The textile machine 1 is an open end spinning machine. It consists of mechanical lower part 2 and mechanical upper part 3. The mechanical lower part 2 has a large number of working positions 4 which receive vacuum via vacuum lines 5 . Furthermore, the mechanical lower part 2 also has a first air conveyor 6 whose function is to generate a negative pressure. The first air conveyor 6 is driven by an electric motor 7 which drives a blower 9 via a belt 8 . The inlet side 10 of the blower 9 is connected to a vacuum chamber 11 in which a conical filter 12 is located. The conical filter 12 is connected on the inlet side to the vacuum line 5 and on the outlet side to the cylindrical section 13 . Behind the cylindrical section 13 there is an adjusting device 14 which can be in the form of a gas flow valve or a flap and regulates the flow path via a conveying device 15 .

[0040] The conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com