Mould holder

A retainer and mold technology, applied in the field of mold retainers, can solve problems such as increased workpiece cost and unfavorable product appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

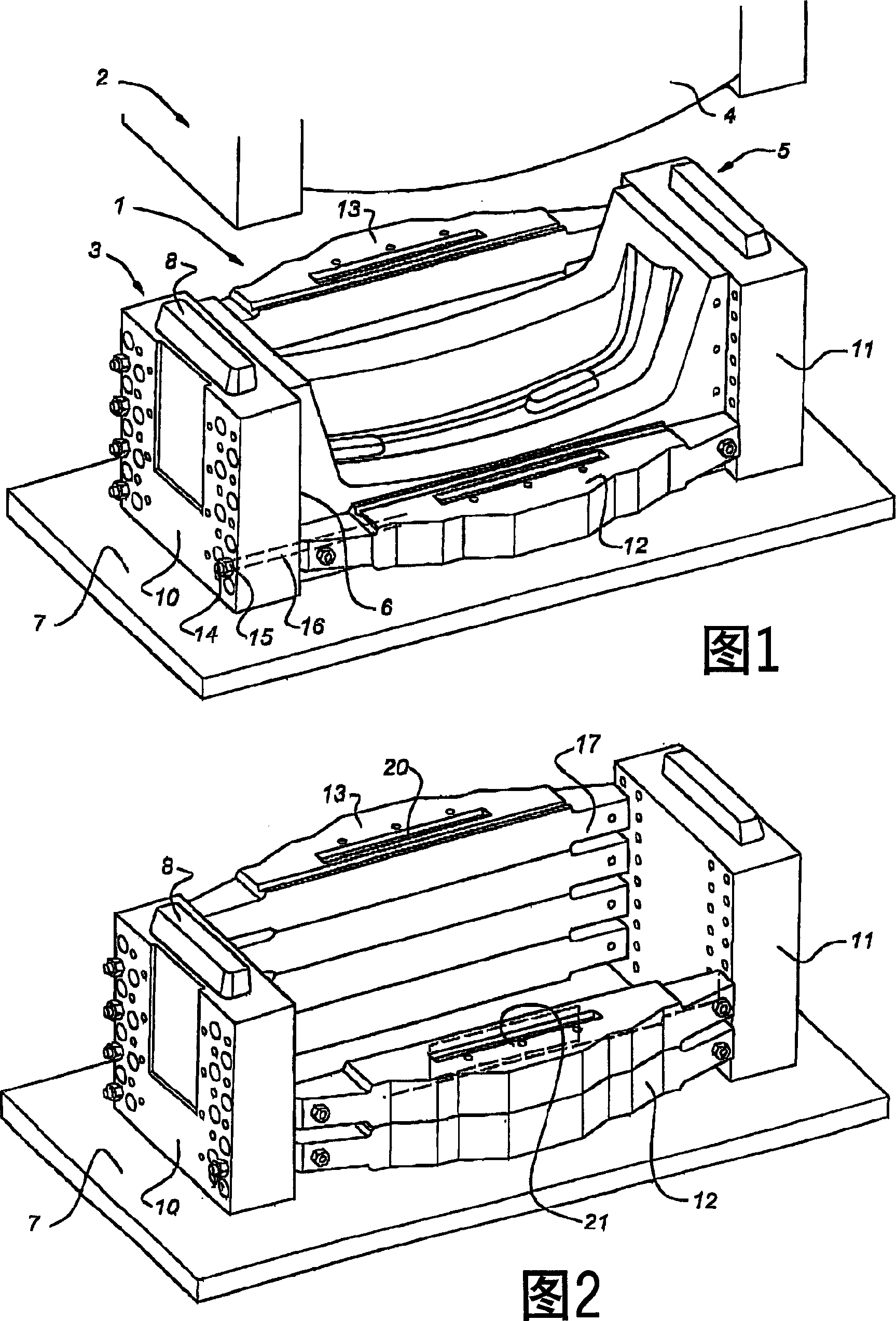

[0016] In FIGS. 1 and 2 , the mold assembly according to the invention is generally indicated with reference numeral 1 . It comprises an upper holder 2 , shown only highly schematically, provided with an upper mold part 4 . The lower holder 3 and the lower mold part 5 arranged therein are shown in more detail. A housing portion 6 in which the lower mold part is accommodated is defined in the lower holder. The lower mold part is provided with a plate 7 for fixing to the injection molding machine, while also having a centering ridge 8 interacting with the upper holder 2 to center the mold parts relative to each other.

[0017] The lower holder comprises end pieces 10 and 11 arranged opposite to each other with spacers 12, 13 interposed therebetween. There is also a tension rod 14 extending through a hole 16, which rod is provided with a nut 15 near its end. There are tension rods in the lower and upper spacers 12 , 13 and they extend through holes 18 in the end pieces 10 , 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com