Method for preparing lactate biosensing strip

A sensing strip, biological technology, applied in the direction of biochemical equipment and methods, microbial determination/inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: the preparation of the graphite paste that contains medium

[0070] 100 mg of graphite powder and polyvinylpyrroline (binder) were mixed with 0.01 M potassium ferricyanide (medium) in ethylene glycol monobutyl ether to prepare a screen-printable graphite paste for the working electrode.

Embodiment 2

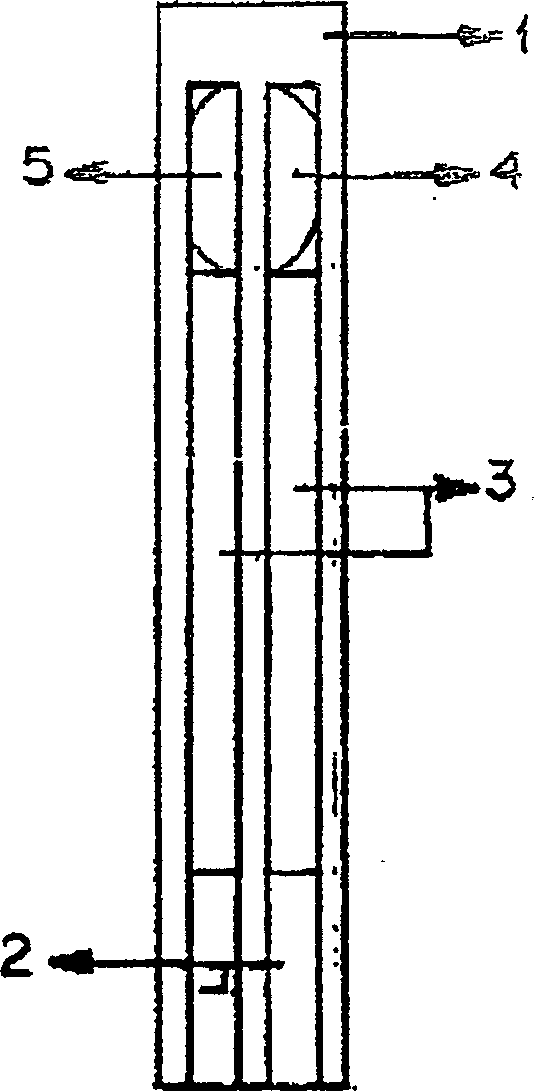

[0071] Example 2: Preparation of Dry Bars

[0072] A commercially available lactate oxidase solution (2 μl) containing 2 U lactate oxidase was physically absorbed on a sensor strip mixed with a graphite electrode medium and kept at 25° C. overnight to dry. The dried electrode was coated with a layer of hydrophilic nylon membrane. Before the film was applied, it was placed in distilled water containing 10% surfactant (Tween 80) for a period of time and the dried film was fixed on the strip.

Embodiment 3

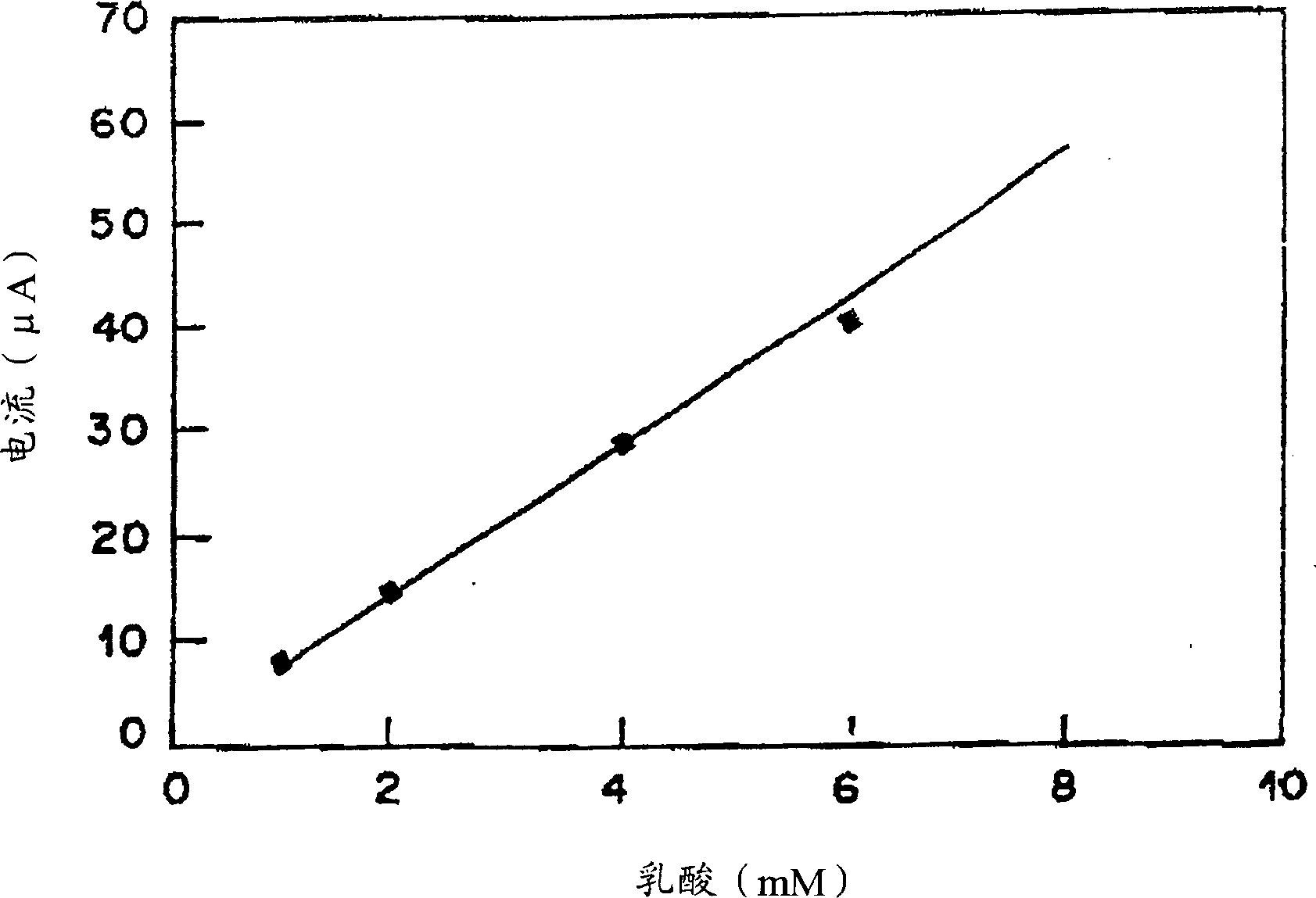

[0073] Embodiment 3: the preparation of lactic acid standard lactic acid solution

[0074] Prepare a 10 mM stock lactic acid solution in 0.1 M phosphate buffer. The stock solution was diluted with phosphate buffer to obtain 2mM, 4mM, 6mM and 8mM standard solutions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com