Photomask and method for creating a protective layer on the same

A photomask and protective layer technology, applied in the field of photolithography, can solve the problems of reducing image quality, not removing photomask pollutants, etc., and achieve the effect of strong resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] refer to Figure 1 to Figure 6 , where the same numerals are used to designate the same or corresponding parts, for the best understanding of the preferred embodiment of the present invention and its advantages.

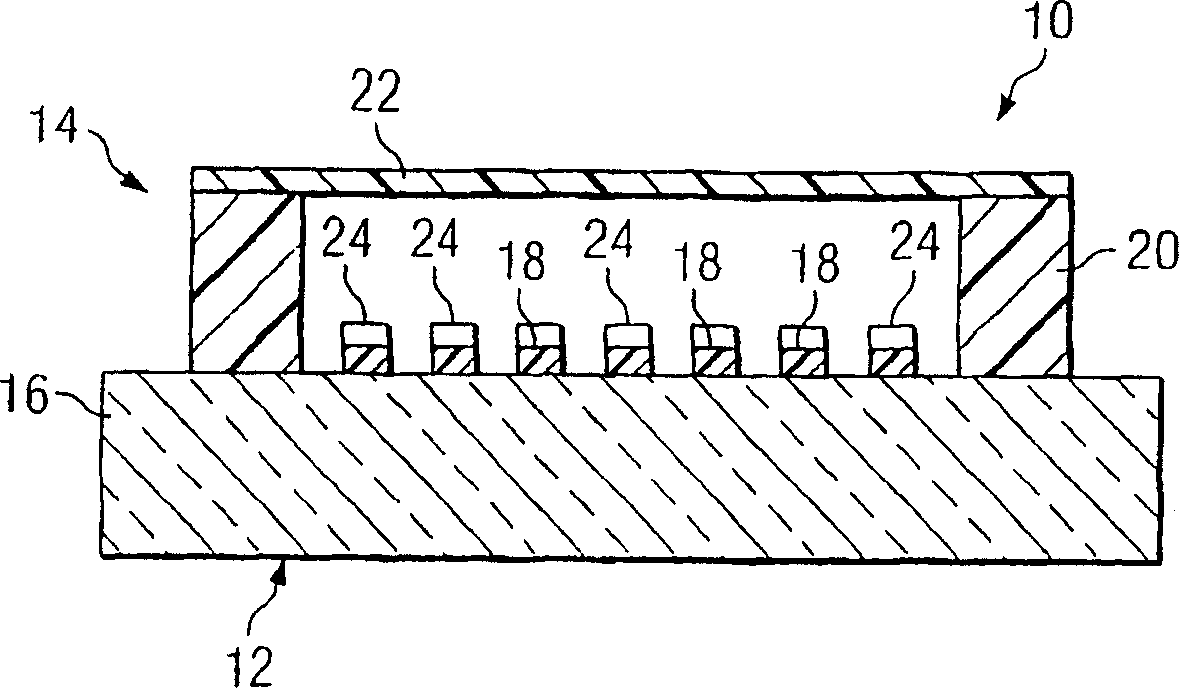

[0022] figure 1 Shown is a cross-sectional view of a photomask assembly 10 that may be inspected by automatically transferring defect images from an inspection system to a database. Photomask assembly 10 includes photomask 12 coupled to pellicle assembly 14 . Substrate 16 and patterned layer 18 collectively form part of photomask 12 . Photomask 12 may also be described as a mask or reticle, which may have a variety of sizes and shapes including, but not limited to, generally circular, circular, rectangular, or square. The photomask 12 can also be any type of photomask including, but not limited to, a disposable master, a 5-inch reticle, a 6-inch reticle, a 9-inch reticle, or one that can be used to project an image of a circuit pattern onto a semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com